Building a pair of Polk Monitor 10's

Options

Comments

-

So today, pulled everything out of the clamps, sanded, and veneered. It would be so much easier if I could use solid wood, but...

Getting closer to final assembly.

Will I am -

Added cross bracing to the fronts. I don't think it needs it but why not. This is far beyond the originals as far as rigidity.

Will I am -

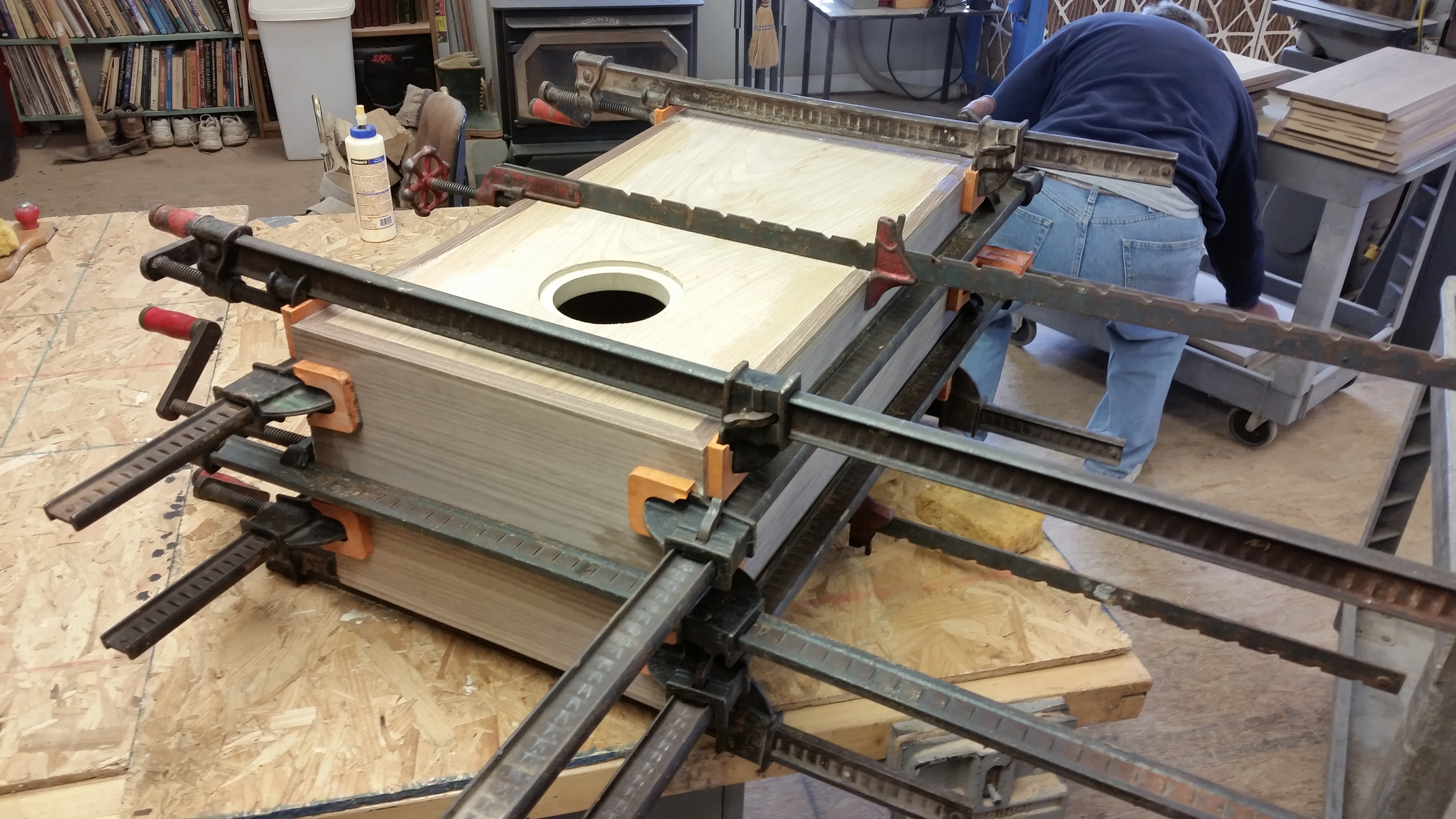

Cut the miters, biscuits, and an army of clamps,

Our first test fit. Looks good.

Will I am -

Beautiful!! Have to say I'm jealous...

-

Man, those are gorgeous. It would almost be a sin to put a grill on them.

BTW, the originals had a front to back brace between the two woofers, starting at the bottom of the woofer opening, running vertically to just below the tweeter opening.

A roll of Dacron was stuffed horizontally behind the tweeter. A second roll, cut like a pair of pants, was inserted behind the woofer openings, with a flap at the bottom.Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

westmassguy wrote: »Man, those are gorgeous. It would almost be a sin to put a grill on them.

BTW, the originals had a front to back brace between the two woofers, starting at the bottom of the woofer opening, running vertically to just below the tweeter opening.

A roll of Dacron was stuffed horizontally behind the tweeter. A second roll, cut like a pair of pants, was inserted behind the woofer openings, with a flap at the bottom.

Very good info. You all are on top of keeping me straight. That was my next question.

Today is final assembly! It is getting stressful. Good stress but this is where all the hard work comes together, so far it looks like our diligent on making accurate cutting pays off.Will I am -

If somebody goes against the rules and the outcome sounds great, does it still count ?

-

Biscuit cutting on the tops, ready for glue.

Will I am -

One down, just enough clamps for two speakers,

Will I am -

Nice work Will.

Any significance/connection to the pic of Fallingwater on the back wall? -

Non intended, but good eye... Been there a couple times. I guess I need to hang the poster straight...Will I am

-

Those are lookin' sweet!!

-

Why are you not cutting in the tweeter to sit flush? It would look better, that is the only thing I don't like, everything else is top shelf...

-

Sanded and test fitting components. There are a couple decisions left. Do I route the tweeter to sit flush, do I chamfer the edge. I like how the walnut frames the oak... routing a perfect gusset for the tweeter is risky. Hence why I was looking for a RDO-194 router template... I'm still trying to figure that one out...

Will I am -

Beautiful!! Those will be the nicest set of 10's on the planet, what am I saying they already are...

-

I see two different options. I could route out 3/8" deep recess just outside the edge of the tweeter. But the face of the RDO is contoured, not flat like the peerless so it looks odd sitting in a recess.

Or I could route to a lip just under the edge of the tweeter and set the tweeter in the recess like a cookie jar lid. Unfortunately there is less than an 1/8" reveal. This would have to be a very accurate cut.

I use a collar on a router to follow an inside profile of a template. The profile is the same shape but larger to compensate for the distance from the collar to the bit. This is an accurate cut. I believe I would have to have a template made on a 3 axis router table.

I could do free hand routing in the center and use sharp wood chisel and wood carving tools.

Still working on it. Or I could mount them as is...Will I am -

You can surface mount the tweeter. I've done it. You need to grind off the lip on the back of the plastic bezel. It will still be raised about an 1/8".Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

How comfortable are you relying on your handworking skills?

-

Dude's got skills!! Those are going to be drop dead gorgeous.Post edited by lightman1 on

-

Those look real nice! The corners are perfect and hard to do. Can't wait to see a finish on them and for the grain to pop. What are you going to use?Polk S10, S8, S4

Polk RT8

Polk Monitor 7s

Working on getting SDAs -

Gorgeous wood work

H9"Appreciation of audio is a completely subjective human experience. Measurements can provide a measure of insight, but are no substitute for human judgment. Why are we looking to reduce a subjective experience to objective criteria anyway? The subtleties of music and audio reproduction are for those who appreciate it. Differentiation by numbers is for those who do not".--Nelson Pass Pass Labs XA25 | EE Avant Pre | EE Mini Max Supreme DAC | MIT Shotgun S1 | Pangea AC14SE MKII | Legend L600 | BlueSound Node 3 - Tubes add soul! -

Didn't think about sanding down the lip on the tweeter... I like that idea...westmassguy wrote: »You can surface mount the tweeter. I've done it. You need to grind off the lip on the back of the plastic bezel. It will still be raised about an 1/8".

Will I am -

I'm with you, I want to see these pop. There are all sorts of finish options. I like to keep it simple and see the wood without stains and color. I use a straight tung oil, rubbed on in several coats. You can finish from a dull mat to a french gloss. Just depends on what you like. I'm shooting for a satin to semi gloss finish. It brings out the grain and darkens to a wet look.deucekazoo wrote: »Those look real nice! The corners are perfect and hard to do. Can't wait to see a finish on them and for the grain to pop. What are you going to use?

Just started the first coat. I like what I'm seeing.

Will I am -

deucekazoo wrote: »Those look real nice! The corners are perfect and hard to do. Can't wait to see a finish on them and for the grain to pop. What are you going to use?

The mitered corners are very difficult, especially biscuiting accurately on a 45! One thing I have learned from working with MDF, you need to take caution in tightening clamps. MDF will crush.

Will I am -

Come on Will this ain't your first rodeo. I bet you could rig those tweeters using hand tools after a few adult beverages and blind folded no problem. Who you kidding. Great workmanship so far. Looking forward to seeing the finished product. Although sight is but one of the aspects of those beuts.

Thank you! Beverages after the ripping is done, a prerequisite to woodworking, especially the sanding.Will I am -

I like to keep it simple and see the wood without stains and color.

Me too, I don't like using stain and it drives me nut when people stain hard wood.

Let the natural color come out.

Polk S10, S8, S4

Polk RT8

Polk Monitor 7s

Working on getting SDAs -

-

-

-

deucekazoo wrote: »

Sorry, but nothing makes the grain of wood pop like a dye and a film coat. New walnut is cold, it needs to be warmed up.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk