Building a pair of Polk Monitor 10's

Comments

-

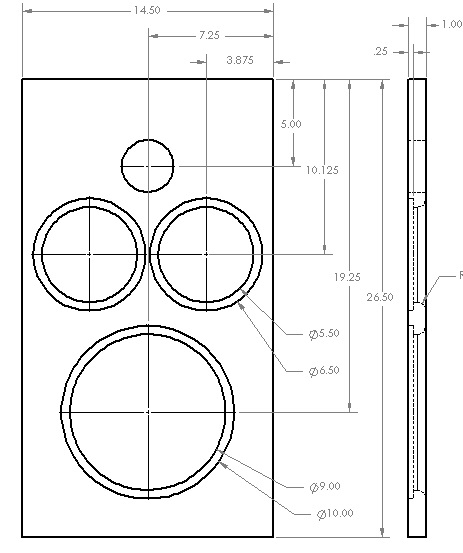

This is the construction drawing I will be following.

Will I am -

As far as aesthetics, the only obvious change is I may laminate the front with an Oak laminate rather than the satin black polk used. We'll have to see how that looks before making any permanent decisions...

Will I am -

Did the coating used on the originals front baffle serve a sonic purpose?

-

Now that is a good question. The only answer I can give is I have seen M10's with painted fronts and others with what appears to be a poly laminate. Did polk test all construction materials including vendor changes and process improvements or did they say that's close enough, we're making money?

I am making my cabinet from MDF, not particle board, and I'm making 1" front and back panels rather than 3/4", so I think in my build it's moot.

If polk had a sonic benefit in mind using a laminate rather than something else, i would be impressed.

Will I am -

I finished my cross overs this evening. Anything I missed?

Will I am -

Stick with nylon risers...the steel will mess with the inductors on the terminal cups.

nbrowser - as you can see I went with the nylon standoffs for the additional riser, but I did use the original steel standoff on the first riser. So I haven't added any additional steel but I also haven't removed any. That meets my build criteria, right or wrong.

Will I am -

Looks good, nice an clean.Polk S10, S8, S4

Polk RT8

Polk Monitor 7s

Working on getting SDAs -

Looks good. Pretty sure those original standoffs were aluminum though.Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

You are correct, the others I bought are steel so even better. My mistake.Will I am

-

-

In the shop today to start cutting pieces.

Will I am -

Nice shop! 3 bandsaws?Beach Audio: Rega RP6 (mods) - AT33PTG/II - Parks Budgie SUT - PSAudio NPC * Eversolo DMP-A6 * Topping D90iii * Joule-Electra LA-100 mkIII * Pass Aleph 30 * MIT S3 * Polk SRS 2.3tl (mods) * PSAudio PPP3

Beach Study: Pro-Ject Stream Box S2 Ultra & Pre Box S2 * Pass ACA * DH Labs SS Q10 * Brines Folded ML-TQWT RS 40-1354 * PSA Dectet

Beach Master: WiiM Pro * Dayens Menuetto * Zu Libtec * Dynaudio Audience 50

Beach Den: Bluesound Powernode 2i * DH Labs SS Q10 * Zu Omen DWII * Richard Gray RGPC

Town Study: WiiM Pro * Chord Qute (Pardo) * Elekit TU-8600 * MIT S3 * Revel M22 * Beyer DT-990 * Shunyata Hydra 2

Town Den: Music Hall mm5.1se - Denon DL-103r - Jolida JD9ii (mods) * WiiM Pro * Cary xCiter * Rogue 99 Magnum * Schiit Aegir * MIT S3 * Polk SRS 1.2tl (mods) * Dectet * Bottlehead Crack - Senn 600

Town Porch: WiiM Pro Plus * Sunfire Sig II * Canare 4S11 * Magnepan 1.6 * Dectet -

-

-

Perfect fit! Now for the real thing!

Will I am -

-

So Monitor 7's are suppose to be the bee's knees when it comes to the series. Let's find out. I had enough material to make a pair of 7's.

Will I am -

-

Very impressed!!! Looks good!!!

-

I like your work! Looking forward to seeing you smile when your finished.

-

Great thread! Been there before a few times..LOL

-

Today is wood laminating day. I decided to do the front and backs in oak. I think this will be a good contrast to the walnut veneer.

Will I am -

After trimming. These will look good after sanding and a clear satin finish.

Will I am -

These are the pieces for the sides and top including the solid walnut for the front.

Will I am -

Last thing we got done tonight was gluing the solid walnut to the sides.

More to come next weekend.

Will I am -

-

-

Getting ready, sanding the sides smooth for the veneer.

Will I am -

Is that your workshop!?!

*subscribed*Where’s the KABOOM?!?! There’s supposed to be an Earth shattering KABOOM!!! -

Will I am