Improvements To Modified SDA SRS 1.2TL Crossover

Comments

-

ignore the stupidity of this question...what would be the disadvantage of going with a high quality lower DCR inductor and adding a decent quality (mills) resistor to bring the DCR back up?

-

ignore the stupidity of this question...what would be the disadvantage of going with a high quality lower DCR inductor and adding a decent quality (mills) resistor to bring the DCR back up?

This is a very good question. In addition to the DCR, an inductor also has a small amount of capacitance due to the dielectric effect of the wire insulation. The larger the wire, the larger the capacitance. I don't know at what point an inductor's capacitance becomes an audible issue. One of our members who designs speakers, like Face, might be able to provide more insight on this.Proud and loyal citizen of the Digital Domain and Solid State Country! -

As long as the DCR is the same and they aren't saturating, I haven't heard much, if any difference between air core inductors. So to use a "high quality, low DCR" coil and add a resistor in series seems redundant to me. I've used Jantzen, Solen, Goertz/Alpha Core as well as some cheepo air cores, and base my choice on the DCR needed and space constraints. What I believe will make a bigger difference, isolating them from vibration by either going external and/or potting them.

I don't believe the minimal difference in capacitance will produce a audible difference either."He who fights with monsters should look to it that he himself does not become a monster. And when you gaze long into an abyss the abyss also gazes into you." Friedrich Nietzsche -

I'm in the camp that simply replacing that which was stock, from top to bottom with higher end components has always done enough for me. I'm not about to sink more money into a loudspeaker I either won't keep or will end up boxed in the closet. Call me jaded but none of this xover stuff is very interesting anymore. The legwork has been high-ended by multiple members, if not even moreso and the rest is up to the individual. Kudos to those guys.

I'm an air-core fan, period.CTC BBQ Amplifier, Sonic Frontiers Line3 Pre-Amplifier and Wadia 581 SACD player. Speakers? Always changing but for now, Mission Argonauts I picked up for $50 bucks, mint. -

Ray,

What gauge of inductors did you use on the small ones?? I may have missed this but just curious but lets say you used 16 ga would going to a smaller gauge work better on the smaller ones??

And Face I like the Idea of going with a external crossover with these upgrades I was thinking about this yesterday as I was pondering what I want to do.. Do the crossovers get warm?? If one was to go external would it be ok to make like a lexan dust cover for them?? -

TOOLFORLIFEFAN wrote: »Ray,

What gauge of inductors did you use on the small ones?? I may have missed this but just curious but lets say you used 16 ga would going to a smaller gauge work better on the smaller ones??

And Face I like the Idea of going with a external crossover with these upgrades I was thinking about this yesterday as I was pondering what I want to do.. Do the crossovers get warm?? If one was to go external would it be ok to make like a lexan dust cover for them??

Lexan is fine since we're not talking closed oven temps on broil. Even heat soak isn't a factor.CTC BBQ Amplifier, Sonic Frontiers Line3 Pre-Amplifier and Wadia 581 SACD player. Speakers? Always changing but for now, Mission Argonauts I picked up for $50 bucks, mint. -

Lexan is fine since we're not talking closed oven temps on broil. Even heat soak isn't a factor.

Thanks Mark,

What is your thought on the vibration to these inductors inside the cabinet?? -

Larry, the only times I've seen people cook their crossover are when:

1. They believe it's a good idea to use their living room stereo for background music when doing yard work.

2. They overdrive their speakers with a less than capable amp.

3. They cover resistors with hot glue/polyfill and listen at loud volumes.

Use common sense and you'll be fine."He who fights with monsters should look to it that he himself does not become a monster. And when you gaze long into an abyss the abyss also gazes into you." Friedrich Nietzsche -

TOOLFORLIFEFAN wrote: »Thanks Mark,

What is your thought on the vibration to these inductors inside the cabinet??

No thought at all. If you secure them with a nice tight wire wrap, to the PCB or whatever structure you have assembled..... unless you are taking psychological medications, you should should be 100% A O K.CTC BBQ Amplifier, Sonic Frontiers Line3 Pre-Amplifier and Wadia 581 SACD player. Speakers? Always changing but for now, Mission Argonauts I picked up for $50 bucks, mint. -

TOOLFORLIFEFAN wrote: »What gauge of inductors did you use on the small ones??

14 ga, same as the large inductor.TOOLFORLIFEFAN wrote: »I may have missed this but just curious but lets say you used 16 ga would going to a smaller gauge work better on the smaller ones??

I don't know. For the other inductors, I think keeping the DCR the same is key.Proud and loyal citizen of the Digital Domain and Solid State Country! -

DarqueKnight wrote: »

I don't know. For the other inductors, I think keeping the DCR the same is key.

DCR is all that matters....the gauge could be all over the place and would be depending on the application.

I'm not saying that directly to you DK, just used the quote.CTC BBQ Amplifier, Sonic Frontiers Line3 Pre-Amplifier and Wadia 581 SACD player. Speakers? Always changing but for now, Mission Argonauts I picked up for $50 bucks, mint. -

Larry, the only times I've seen people cook their crossover are when:

1. They believe it's a good idea to use their living room stereo for background music when doing yard work.

2. They overdrive their speakers with a less than capable amp.

3. They cover resistors with hot glue/polyfill and listen at loud volumes.

Use common sense and you'll be fine.

LoL!!! I would never do that I was just curious if it would be ok to cover your External Crossovers just to keep dust off them. I wasn't sure if they got warm enough to cause any damage to them..

Don't get me wrong I pushed my speakers hard a couple of times just to see what they would do. Only for short periods of time but that has passed They get loud enough from time to time without pushing the limits. Personally I think they sound better at moderate levels. the SDA effect sounds better as well.. -

DCR is all that matters....the gauge could be all over the place and would be depending on the application.

I'm not saying that directly to you DK, just used the quote.

Then why do you think DK had no improvements with the smaller inductors? but the 16mh inductors seems to be the way to go?? -

I wouldn't expect a glaringly obvious change either. Not every tweak is going to knock your socks off, or change the world. I stick to stock tolerances as a guide and go with better components when I rebuild my xovers. The inductor isn't the heart and soul of a loudspeaker xover, just the meat and it's easy to do. It's just a winding but what kind of winding can make a big difference depending on era and blah blah. DK and Face have a better attack of explanantion than I do since I have moderate interest in doing so at all.

You could go from wild to mild when it comes to inductors and gauge, just keep within tolerance of the original DCR unless your tweaking or DIY....just keep to stock for rebuilds of SDA xovers. The cost is always something that should play a role and why go larger if you can go smaller and better, yet achieve the same DCR? The same stuff you do with caps and sizes. And who knows what might be on sale that week? See where I'm coming from?

Inductors weren't even an issue until recently for some reason or another and the LSi15 was my very first full bore rebuild of a Polk current. Vintage are much easier to work on. I hated that project and it sucked life out of me. Face has also worked a LSi15 and while he's more crafty than I am, can at least attest to it being a PITA.

All the rest was smash and grab stuff. Everyone was replacing caps and resistors and it was a woo hoo event for a year or so. Then the usual upgrade bug took over....only one thing left. Inductors.

I was certainly no pioneer but always advocated doing inductor work since my project with North Creek on another unrelated project ages ago. I always replace inductors, period. Why not? If I'm putting in man hours to trip out a speaker, fix it or do whatever, why not?CTC BBQ Amplifier, Sonic Frontiers Line3 Pre-Amplifier and Wadia 581 SACD player. Speakers? Always changing but for now, Mission Argonauts I picked up for $50 bucks, mint. -

Ray, Your reviews are worthy the best HiFi mags. I am happy to see that I got the inductor placement spot on.HT/2 CH

McIntosh MX120, MC500, MC206, MEN220

polkaudio SDA SRS 1.2TL, XO, Inductor, Tweeter, Larry's rings, WBT Binding posts, Moretite and Dynamat mod. Built by Mollie Jones 27:th of February 1991, CS350-LS XO mod, LS-f/x, DSW MicroPro 4000

MIT Shotgun S3.3 Bi-wire SC, Shotgun S3.3 SC, Shotgun S3.3 Proline IC, Shotgun S3.3 IC, Shotgun S3.3 Sub cable, AVT 1 Optical IC, EXP 3 Speaker interconnect. -

DK, cant wait to see how the x-over will look for your SRS's.

Your wait is over!

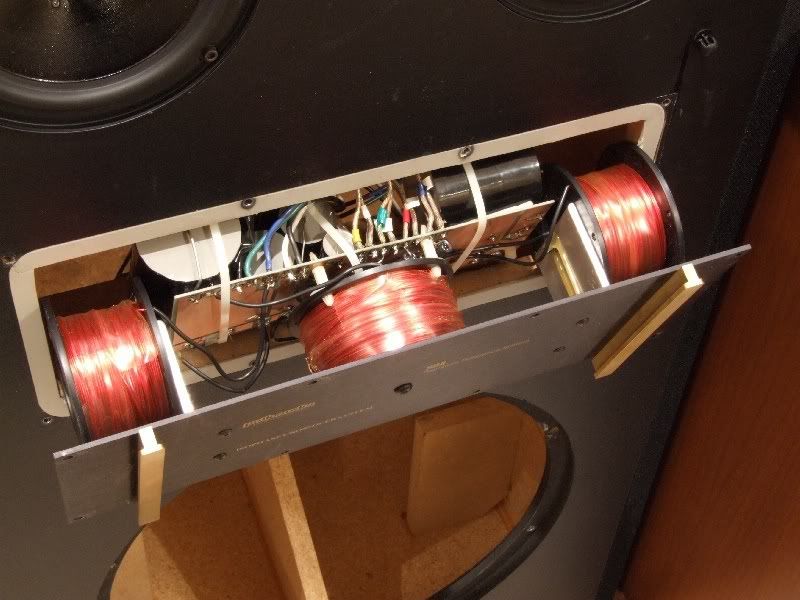

I went from this:

Figure 1. SRS crossover wires soldered directly to the board.

and this:

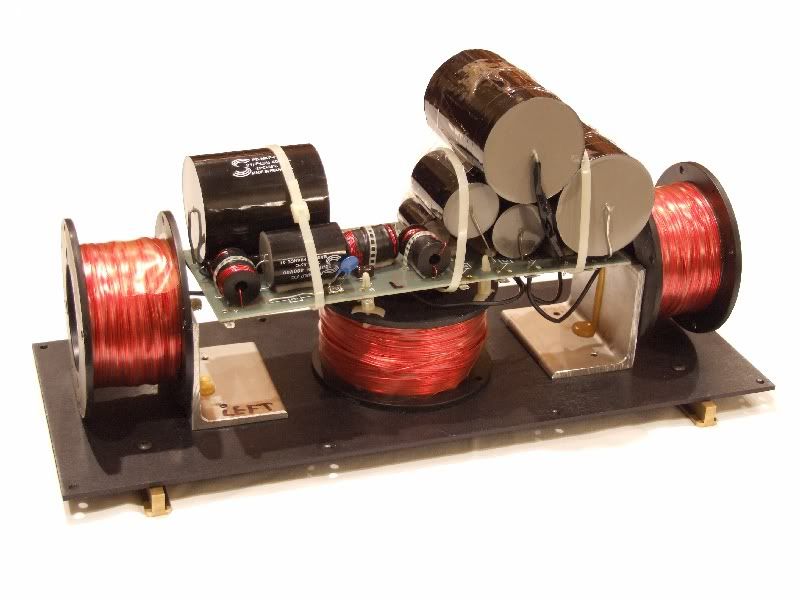

Figure 2. A big pile of SRS crossover goodness...but a mess.

to this:

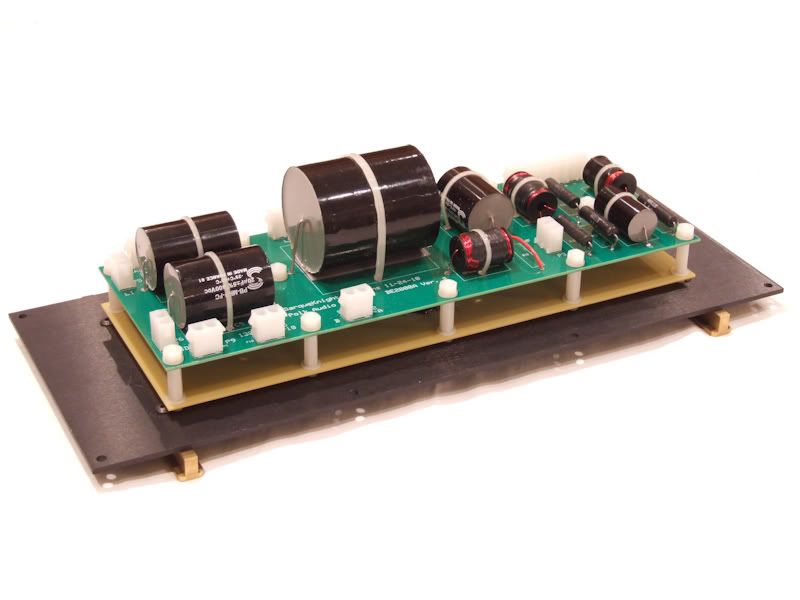

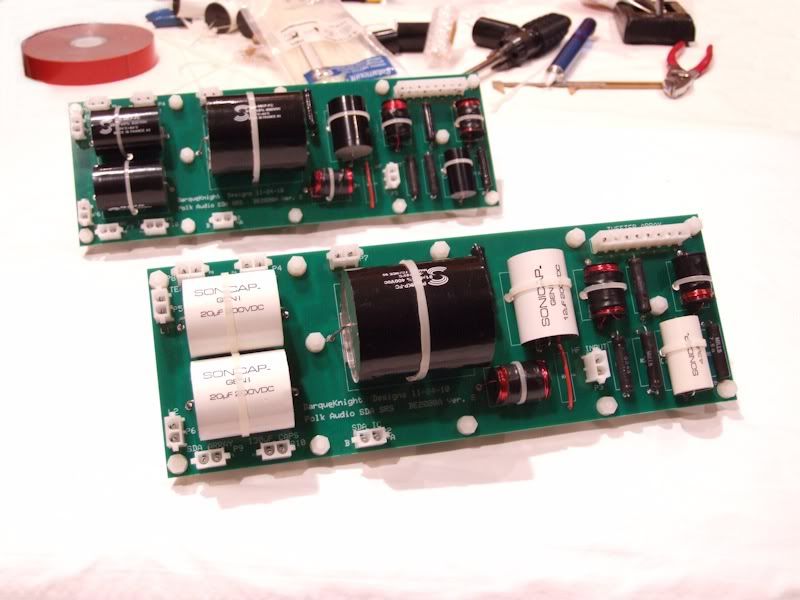

Figure 3. New SDA SRS crossover assembly: main board, support board and crossover cover plate.

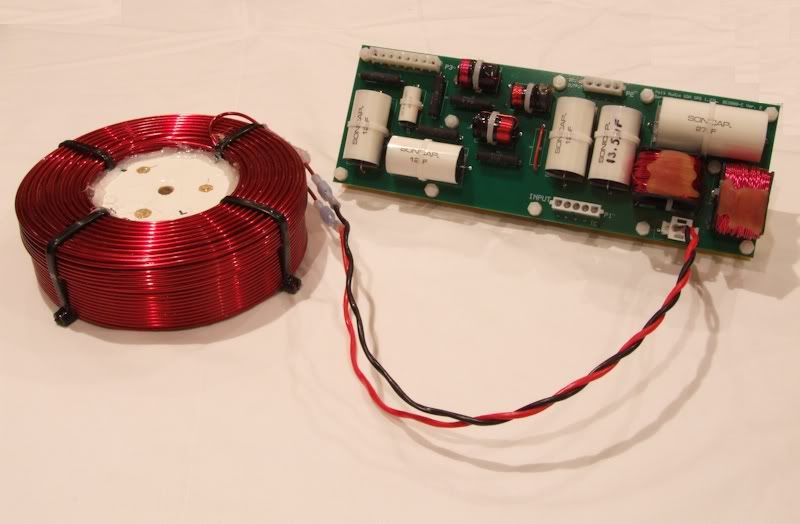

Figure 4. Left to right: 130uf capacitor board, main board, 16 mH Northcreek inductor, stock 2.75 mH inductors.

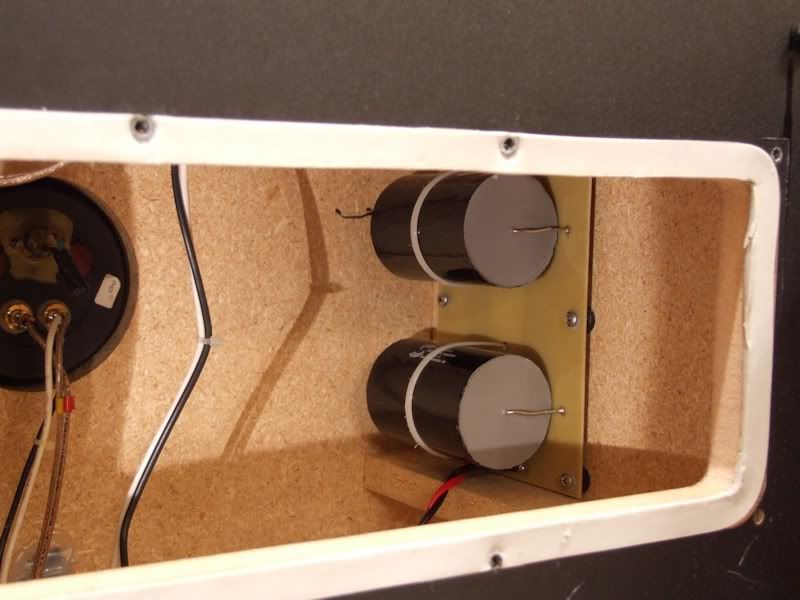

Figure 5. The soup can sized 130 uF Solen capacitors were mounted on a separate circuit board tucked in the corner.

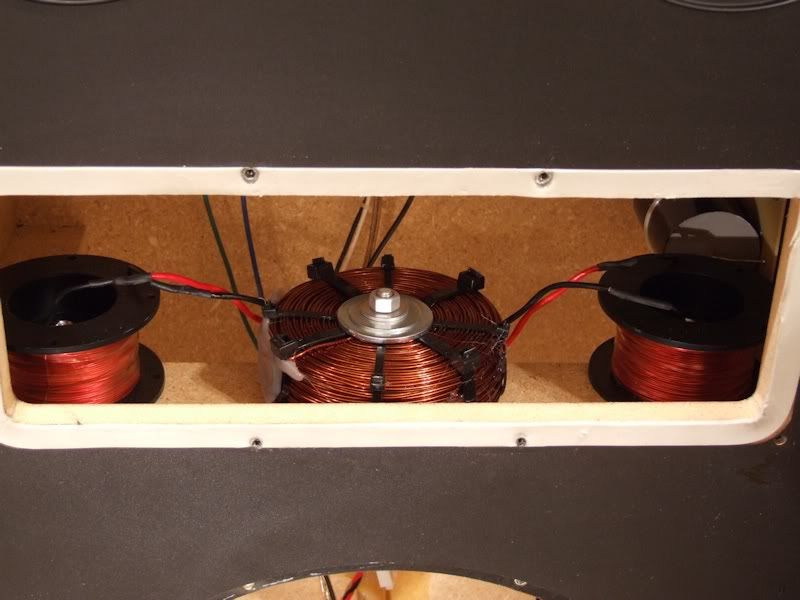

Figure 6. Large inductor mountings. There is a cabinet brace just below the crossover opening that is 4" wide at the front and 1" wide at

the sides. It provided a good place to mount the 2.75 mH and 16 mH inductors. The inductors were mounted with aluminum nuts and

bolts.

Figure 7: Back during the Jurassic, when my SDA SRS's were manufactured, Polk had not started to use the nice wiring harnesses that

were used with later SDA speakers. The original connections were of the soldered and metal tab/quick disconnect type. I replaced all of

those with plug-in wiring harnesses.

More later after listening evaluations and burn in are completed.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Wow man that is quite a difference.

-

hearingimpared wrote: »Wow man that is quite a difference.

Defintitely...sound wise as well as looks wise.:biggrin:Proud and loyal citizen of the Digital Domain and Solid State Country! -

^^^^ Thou art a tease!

-

VERY, VERY Nice. Great job and looks good.:cool:“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain

-

On the 8th day God created Ray!!!

Very nice work champ!!! -

TOOLFORLIFEFAN wrote: »On the 8th day God created Ray!!!

Very nice work champ!!!

On the 9th Nat King Cole and on the 10th Ella Fitzgerald!!! That's some great company Ray!!! When in heaven I can see you blowing that sax and boogieing with Nat and Ella! -

Very clean Dr.

Now just get rid of those Solen's on the highs!Please. Please contact me a ben62670 @ yahoo.com. Make sure to include who you are, and you are from Polk so I don't delete your email. Also I am now physically unable to work on any projects. If you need help let these guys know. There are many people who will help if you let them know where you are.

Thanks

Ben -

Now just get rid of those Solen's on the highs!

I thought about doing that, but the required 91 uF capacitor (that big one in the middle of the board) presented some problems. Most film cap manufacturers don't seem to like to make values over 30 uF. Besides, the SRS's do light 2 channel duty and mostly 5 channel, front speaker, duty in the home theater system, so Solens are fine. Proud and loyal citizen of the Digital Domain and Solid State Country!

Proud and loyal citizen of the Digital Domain and Solid State Country! -

Now just get rid of those Solen's on the highs!

I changed the capacitors in one of my CRS+ pairs from AudioCaps to Sonicaps and the improvement in clarity was fantastic! I was able to do a direct comparison between a pair of CRS+'s with the Sonicaps and an identical pair with AudioCaps.

AudioCaps are better than Solens and Sonicaps are better than AudioCaps, so Sonicaps are much better than Solens and I decided to ditch the SRS's Solens (except for the very large value 130 uF and 91 uF caps). Proud and loyal citizen of the Digital Domain and Solid State Country!

Proud and loyal citizen of the Digital Domain and Solid State Country! -

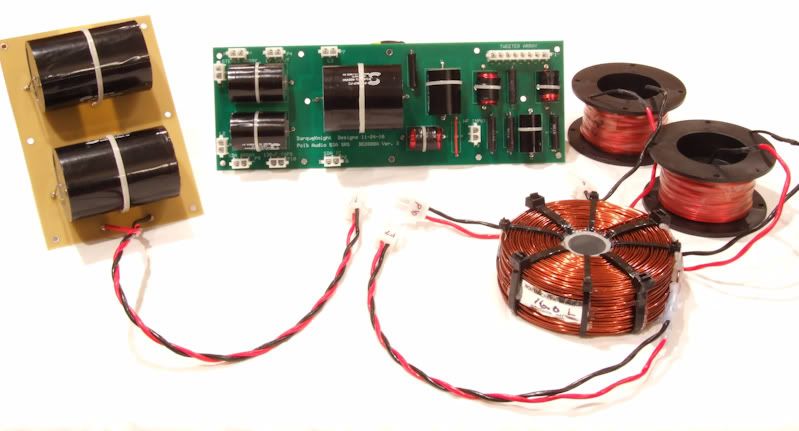

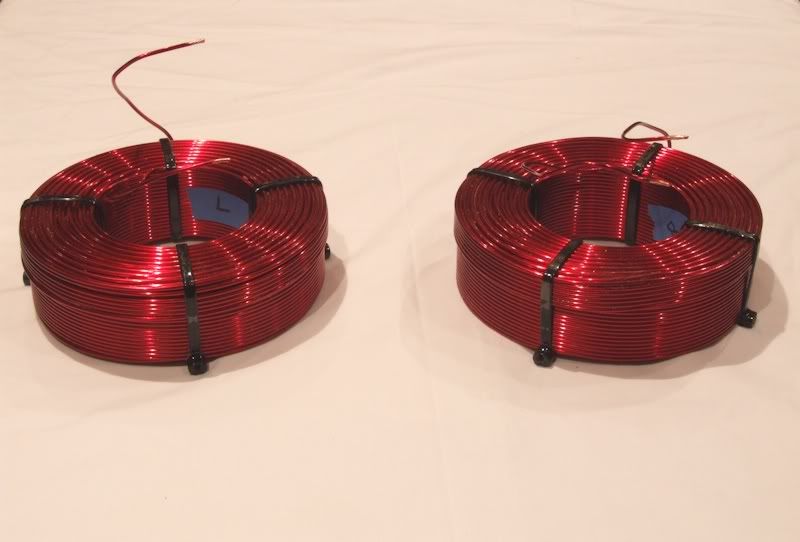

An SDA comrade-in-arms, Janne, suggested that, since we had such good results with the Northcreek 14 AWG inductors in our SDA SRS 1.2TL's, we should not stop there. He thought we should investigate Solen's 10 AWG 16 mH inductors. I thought this was a good idea too.

Partsconnexion in Canada didn't stock these inductors but they could order them. I realized an overall 15% savings from the price at the Solen website. I received my inductors 18 days after placing the order. Total price was $416 for the pair.

Figure 1. Solen 10 AWG, 16 mH inductors: 2.5" high x 7.5" outside dia. X 4" inside dia. Weight: 17.1 pounds (L), 17.3 pounds (R).

Both Solen inductors measured 15.4 mH and 0.8 DCR. The DCR's of the Northcreek inductors was 1.3 ohms. The DCR's of the stock inductors was 2.8 ohms.

The total DCR of the 1.2TL's went down to 3.0 ohms (R) and 3.1 ohms (L) with the Solen inductors. The speaker DCR's with the Northcreek inductors was 3.4 ohms each speaker. The speaker DCR's with the stock inductors was 3.8 ohms (L) and 3.9 ohms (R).

The Solen inductors are manufactured using a high precision honeycomb structured perfect lay hexagonal winding technique. The alternating current passing through an inductor will induce an alternating magnetic field, which will produce a mechanical vibration in each turn of wire corresponding the applied audio frequency. This mechanical vibration generates an acoustic radiation that will cause a non-linear loss and distortion which causes audio frequency noise. The high precision perfect lay hexagonal winding technique eliminates most electro-mechanical vibration losses. Each inductor is dipped in an industrial varnish that impregnates and totally solidifies all the outside turns.

Figure 2. L-R 16 mH inductors: Solen 10 AWG, Northcreek 14 AWG, stock 18 AWG. The stock SDA inductors, like those horrible

polyswitches, are bottlenecks to better sound.

Figure 3. This project required a bit of carpentry work. Spools for the inductors were made of three 3/4" thick MDF discs screwed

together and hot glued to the inductors. Wear a face mask if you try this at home. MDF dust is nasty stuff...and carcinogenic.

Figure 4. To add support for the narrow (2") brace that the 17 lb. inductors will rest on, two 1.5" #10 brass wood screws were

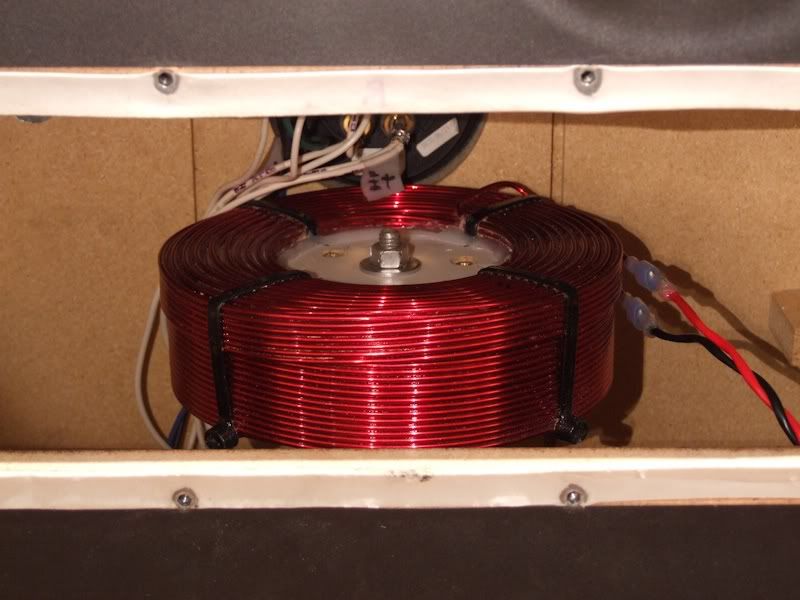

installed at each end of the brace from the cabinet exterior.

Figure 5. Solen inductors with MDF spools installed.

Figure 6. Custom crossover with Solen SDA inductor.

Figure 7. Solen inductor installed.

Preliminary Measurements

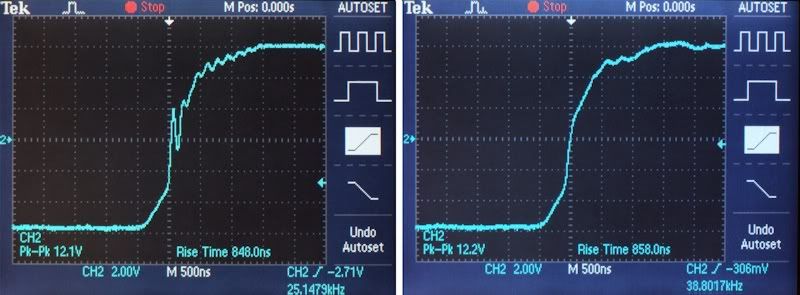

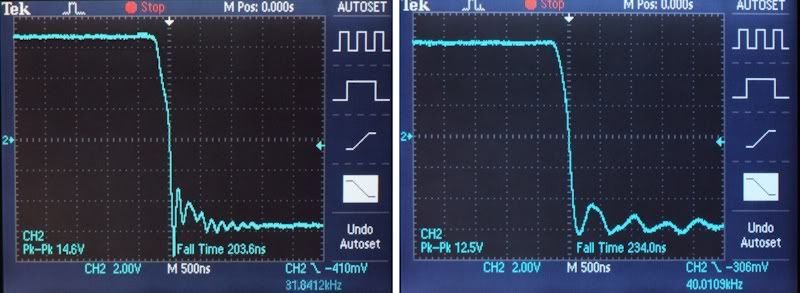

The Solen inductors exhibited much better measured noise performance prior to conditioning on the Cable Cooker compared to the Northcreek inductors. Figures 8 and 9 show the outputs of the Northcreek 14 AWG inductors (left) and Solen 10 AWG inductors at the beginning of conditioning on the Audiodharma Cable Cooker.

Figure 8. Rising edge of the Cable Cooker's conditioning signal pulse from the Northcreek inductors (left) and Solen inductors

(right) at the beginning of conditioning.

Figure 9. Falling edge of the Cable Cooker's conditioning signal pulse from the Northcreek inductors (left) and Solen inductors

(right) at the beginning of conditioning.

Preliminary Listening Evaluation

The Solen inductors enhanced the improvements brought by the Northcreek inductors with the additional benefit of significant improvement in center image weight, clarity and detail.

A more extensive listening evaluation will be done after the Solen inductors complete conditioning on the Cable Cooker.

The Northcreek inductors are going into a pair of SDA CRS+'s.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Those inductors are HUGE:eek:Please. Please contact me a ben62670 @ yahoo.com. Make sure to include who you are, and you are from Polk so I don't delete your email. Also I am now physically unable to work on any projects. If you need help let these guys know. There are many people who will help if you let them know where you are.

Thanks

Ben -

I did not visually detect any sagging when the inductor was placed on the brace. I used the Shelf Sag Calculator at http://www.woodbin.com/calcs/sagulator.htm to compute the amount of deflection caused by a 17.3 pound center weight on an end supported 3/4" thick 2" x 10.5" piece of MDF. The calculator specified 0.00" total deflection without real world correction factors included and 0.01" deflection with real world correction factors included. The eye can detect deflection of 0.03" per running foot.

Over time, an additional 50% sag can be expected, which in the case of this brace would still be visually undetectable. However, since the brace is in a vibration prone environment, sag greater than 50% might be realized. But then again, I probably won't get any sag since the inductor's 7.5" diameter covers 71% of the brace's 10.5" span and the center of the span is bolted to the load. This acts as a rigid reinforcement against sagging and provides a near uniform load across the brace rather than a center load.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Proud and loyal citizen of the Digital Domain and Solid State Country!

-

DK you just got too much money and spare time on your hands.

BTW: Did you ever get an answer back on the schematics ?“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain