Monitor 10 Crossover Rebuild

Comments

-

Waking this thread up again. My nephew Brendan and I are going to tear into his Monitor 10's this weekend. We've had the parts for a while now, but on my advice we held off for a little bit before getting started with the mods. I told him that it was important for him to get his ears used to what the speakers sound like before any mods, so he can better appreciate the improvements that he gets for the money that he's spending on the upgrades. Otherwise, in the back of his mind he'll be wondering if the upgrades made much of a difference.

So while he has had the speakers in hand, he put new cloth on the grills using the leftovers I had from when I did my 4.1TL's. Luckily my leftovers were the perfect size he needed for his two grills!

This weekend we'll do the caps (Sonicaps for the highs, Dayton for the shunt), the resistors (went with the Mills 10W for the 2R4's, as hoped Elliot was able to find a matched pair that read higher than 2.4, so definitely within spec for the 2.5 +/- 5%). We have the binding posts from eBay, and we'll be applying the Blackhole 5 strips as Dave instructed. We'll re-do the internal wiring with Cardas Litz, install the hurricane nuts, and apply the dynamat and armacell seals. And thanks to Larry for sending me a batch of the black oxide screws he supplied with his rings!

Looking forward to getting this work done so Brendan can start breaking the caps in. I'll follow up with some pics after we do the work.Good music, a good source, and good power can make SDA's sing. Tubes make them dance. -

Sounds like fun!Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

Looking forward to pics. I have a pair of 10's that I will be upgrading very soon. Just got them put together with spare parts I had lying around but want to do a decent crossover upgrade, posts, possible rewire internal wiring, veneer job, spikes, ect....

Pics of step by step would be wonderful to see.2-ch System: Parasound P/LD 2000 pre, Parasound HCA-1000 amp, Parasound T/DQ Tuner, Phase Technology PC-100 Tower speakers, Technics SL-1600 Turntable, Denon 2910 SACD/CD player, Peachtree DAC iT and X1asynchorus USB converter, HSU VTF-3 subwoofer. -

So my nephew and I ran out of time this weekend, didn't get a chance to do both speakers. But we completely finished one speaker and got it all reassembled. So we have one completely rebuilt, the other completely stock. We should finish the other speaker this coming weekend. Meanwhile, he set his preamp to Mono, and has both speakers playing the same signal, and is comparing the modded to the stock. He is pretty amazed at how much better the modded speaker sounds than the one with no work done, and that's before any substantial break-in time.

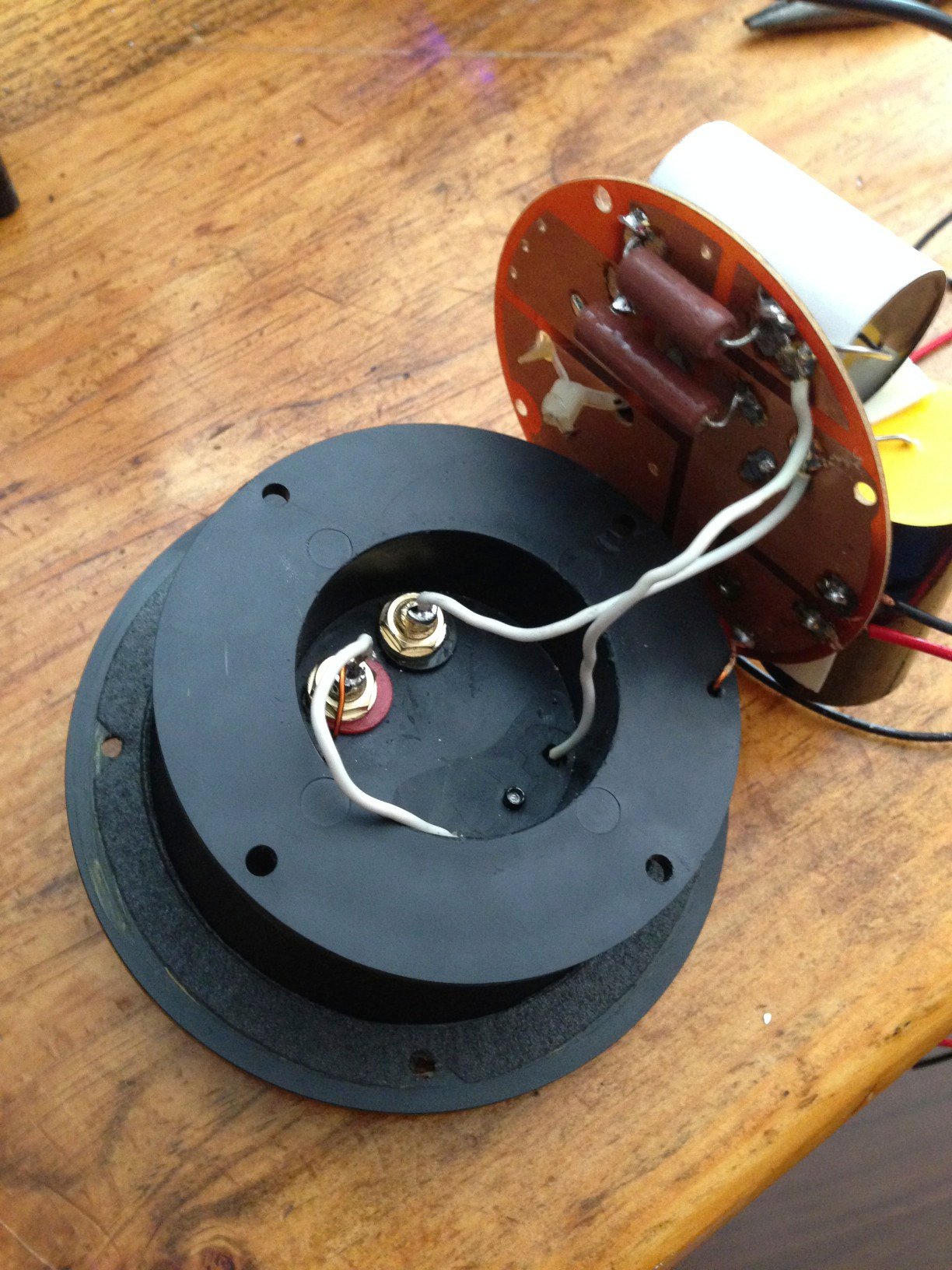

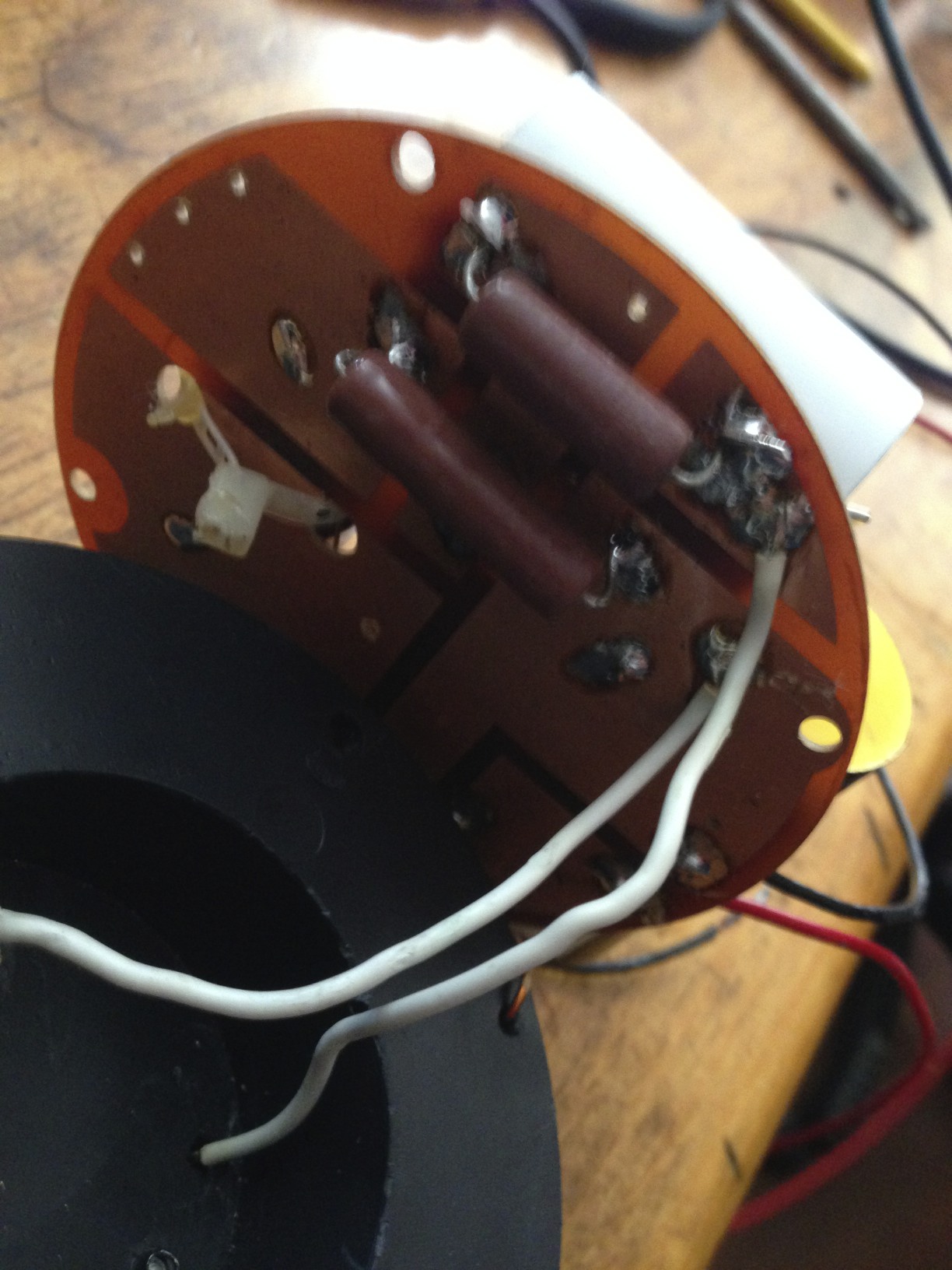

Here are a few pics. Mills resistors undermounted:

Crossovers and Blackhole 5 installed

And the reason we didn't have time to finish, I had to get home and cook this gorgeous Tri-Tip: Good music, a good source, and good power can make SDA's sing. Tubes make them dance.

Good music, a good source, and good power can make SDA's sing. Tubes make them dance. -

did you glue everything down...?Marantz 1152 DC- Denon DP 1200, Soundsmith Carmen MKII- ADS L980 - Blue Jeans IC's

-

Looks great.......including the tri-tip

-

Looks greatHome Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

I did not glue it all down. So far just double sided tape. I really don't like pouring glue all over everything. I was considering drilling a few holes in select locations in order to accommodate some cable ties.Good music, a good source, and good power can make SDA's sing. Tubes make them dance.

-

That's what I do.I did not glue it all down. So far just double sided tape. I really don't like pouring glue all over everything. I was considering drilling a few holes in select locations in order to accommodate some cable ties.Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

By the way, Dave - now I understand why you were saying the binding posts were a PITA. They sit inside the cup, making it hard to work on them. I pushed the leads through the holes I drilled for the posts, and did the soldering before I inserted the posts into the cup. But the leads are not very long, so steadying everything for the soldering was tricky. Like you said - PITA!Good music, a good source, and good power can make SDA's sing. Tubes make them dance.

-

Well this project is done! Brendan and I finished the other speaker last night. He's got a nice little rig going! Modded Monitor 10's, modded NAD 2200 amp, NAD 1155 preamp, and a Squeezebox Touch. His Signal Cable speaker cables and interconnects arrive on Monday. We're planning to do some cap and opamp upgrades to his preamp and some point down the road.

Thanks for all the advice, it was invaluable!Good music, a good source, and good power can make SDA's sing. Tubes make them dance. -

I am sure he will appreciate and love his first set of polks and the rest of the gear.

-

Glad everything worked out for you. I use a pair of "Helping Hands" to hold the post and wire while I'm soldering.By the way, Dave - now I understand why you were saying the binding posts were a PITA. They sit inside the cup, making it hard to work on them. I pushed the leads through the holes I drilled for the posts, and did the soldering before I inserted the posts into the cup. But the leads are not very long, so steadying everything for the soldering was tricky. Like you said - PITA!Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

Well this project is done!

No...NOT DONE! Not done at all! Good Pics (as promised in post #62) or it didn't happen, Neil. You know better than that! ;-)

Did you ever get the styrofoam fungi off the cabinets? What worked, or didn't work, for that?

How did you like working with the hurricane nuts? Did that go smoothly? Did you use any glue/epoxy with them? On the PE linked page, customer reviewers seemed to be most pleased when they used epoxy.

How did the redo of the grille cloth go? Same cloth as used on your 4.1TLs? Link?

More info on the budget BPs linked by Dave - do you like them? Are these good ones to use with any of the Monitor 10s? I noticed they have a shorter threaded shaft than the Cardas and Vampires I used on my SDA2BTLs and was wondering if this length was better for my 10Bs. I'm thinking that the longer shafted ones might not work as well with the 10Bs since the crossover component board might be too close and not leave enough room for the full BP shaft under it. Can you (or Dave) comment a little more on the PITA part of mounting/connecting the BPs for those of us who couldn't quite follow the earlier narrative?

Lastly, good on you, Neil, for doing this with your nephew! That's likely a pair of speakers he'll have for a very long time and appreciate your introducing him to this great hobby, often and for years to come. Well done! -

teekay0007 wrote: »No...NOT DONE! Not done at all! Good Pics (as promised in post #62) or it didn't happen, Neil. You know better than that! ;-)

Did you ever get the styrofoam fungi off the cabinets? What worked, or didn't work, for that?

How did you like working with the hurricane nuts? Did that go smoothly? Did you use any glue/epoxy with them? On the PE linked page, customer reviewers seemed to be most pleased when they used epoxy.

How did the redo of the grille cloth go? Same cloth as used on your 4.1TLs? Link?

More info on the budget BPs linked by Dave - do you like them? Are these good ones to use with any of the Monitor 10s? I noticed they have a shorter threaded shaft than the Cardas and Vampires I used on my SDA2BTLs and was wondering if this length was better for my 10Bs. I'm thinking that the longer shafted ones might not work as well with the 10Bs since the crossover component board might be too close and not leave enough room for the full BP shaft under it. Can you (or Dave) comment a little more on the PITA part of mounting/connecting the BPs for those of us who couldn't quite follow the earlier narrative?

Lastly, good on you, Neil, for doing this with your nephew! That's likely a pair of speakers he'll have for a very long time and appreciate your introducing him to this great hobby, often and for years to come. Well done!

I can comment on the PITA Binding Posts. With the Monitor, and RTA Series, the back of the binding post cup is at the bottom of the spool inductor. Getting down there to tighten the lock nuts is difficult if you solder the leads. If you go with large crimp ring terminals instead of solder, you could use a thin-wall socket wrench or nut driver, and it would be easier. I choose to solder. The leads must be long enough to slide the lock nut and plastic washer on, then thread through the hole, then slide the shoulder washer and clear trim piece on. Then solder the lead to the binding post. Home Theater/2 Channel:

Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/ -

teekay0007 wrote: »No...NOT DONE! Not done at all! Good Pics (as promised in post #62) or it didn't happen, Neil. You know better than that! ;-)

Did you ever get the styrofoam fungi off the cabinets? What worked, or didn't work, for that?

How did you like working with the hurricane nuts? Did that go smoothly? Did you use any glue/epoxy with them? On the PE linked page, customer reviewers seemed to be most pleased when they used epoxy.

How did the redo of the grille cloth go? Same cloth as used on your 4.1TLs? Link?

More info on the budget BPs linked by Dave - do you like them? Are these good ones to use with any of the Monitor 10s? I noticed they have a shorter threaded shaft than the Cardas and Vampires I used on my SDA2BTLs and was wondering if this length was better for my 10Bs. I'm thinking that the longer shafted ones might not work as well with the 10Bs since the crossover component board might be too close and not leave enough room for the full BP shaft under it. Can you (or Dave) comment a little more on the PITA part of mounting/connecting the BPs for those of us who couldn't quite follow the earlier narrative?

Lastly, good on you, Neil, for doing this with your nephew! That's likely a pair of speakers he'll have for a very long time and appreciate your introducing him to this great hobby, often and for years to come. Well done!

Afraid I broke my promise, didn't take any additional pictures, sorry about that.

To answer your questions - yes, styrofoam came off easily with denatured alcohol as Dave suggested. Didn't even require any elbow grease.

The hurricane nuts went ok, there is one nut on one driver that is spinning loosely, but it's already been tightened down very substantially. It might be a good idea for us to go back and hit it with some epoxy so it holds tight.

Grill cloth isn't done yet, all he's done so far is pull the old cloth and staples, and then hit the frames with some black spray paint.

The Dayton shunt caps worked out fine. I haven't auditioned M10's with higher end shunt caps versus the Daytons, but the speakers sound great. Plenty of clean bass.

The BPs Dave recommended are fine. As Dave said, it's a pain in the neck to twist down the nut after you've soldered the connection (I didn't use a crimp ring either), a longer post might have helped. But we got it done without too much difficulty. If you're mounting them on something that's flat as opposed to a cup (like Trey's binding post plate) it would be a breeze.

It was a great time doing a project like this with my nephew, best part is seeing how happy he is with the end result. He's got a great sounding system and he is really enjoying it!Good music, a good source, and good power can make SDA's sing. Tubes make them dance. -

westmassguy wrote: »I can comment on the PITA Binding Posts. With the Monitor, and RTA Series, the back of the binding post cup is at the bottom of the spool inductor. Getting down there to tighten the lock nuts is difficult if you solder the leads. If you go with large crimp ring terminals instead of solder, you could use a thin-wall socket wrench or nut driver, and it would be easier. I choose to solder. The leads must be long enough to slide the lock nut and plastic washer on, then thread through the hole, then slide the shoulder washer and clear trim piece on. Then solder the lead to the binding post.

Thanks Dave. It sounds like the first step is to lengthen the leads that are connected to the BPs so you can even work with them.

Are you and your customers pretty happy with their overall performance? Do they stay firmly in place, hold onto bananas and spades nicely and conduct properly? They look a lot like the ones Polk now uses on the LSiM series.

Is soldering just your personal preference, or is it that soldering makes a better electrical connection than the crimp ring terminals? -

I use them on all my own speaker when I replace them. They're very solid, and heavy. Pure copper with gold plating. Not a brand name for sure, but everyone's been happy with all the ones I've done. I prefer soldering, because I know in 5 or 10 years, the Cardas Quad Eutectic will still be there. Some crimp terminals corrode at the wire connection, and the binding post connection. Rather be safe than sorry down the road.Home Theater/2 Channel:

Front: SDA-2ATL forum.polkaudio.com/discussion/143984/my-2as-finally-finished-almost/p1

Center: Custom Built forum.polkaudio.com/discussion/150760/my-center-channel-project/p1

Surrounds & Rears: Custom Built forum.polkaudio.com/discussion/151647/my-surround-project/p1

Sonicaps, Mills, RDO-194s-198s, Dynamat, Hurricane Nuts, Blackhole5

Pioneer Elite VSX-72TXV, Carver PM-600, SVS PB2-Plus Subwoofer

dhsspeakerservice.com/