Goodbye Binding Post Cup. 1.2tl's

Comments

-

How can I get these??

There was a member named Musky who did some of these as one off's for the forum. I don't believe he is making anymore of them, but feel free to contact him and see."....not everything that can be counted counts, and not everything that counts can be counted." William Bruce Cameron, Informal Sociology: A Casual Introduction to Sociological Thinking (1963) -

I decided to take a cue from Roger Russell and rewire my SDA SRS 1.2TL's with Cardas copper Litz wire in 15.5 gauge. The Cardas wire is slightly larger than the stock wire, which is 16 gauge. This is the same wire that Mr. Russell uses in his $18,000 IDS-25 loudspeaker system. However, Mr. Russell does not believe the Cardas wire offers any sonic advantage over ordinary wire. He just uses it for marketing reasons. [Link: Cardas wire and the IDS-25]

There is nothing wrong with the stock wire. I just want to see if the better wire makes a difference in this application. The Cardas wire is a lower noise design due to the Litz configuration (reduction of strand interaction by insulating individual wire strands) and due to the polished surface of the conductors. AudioQuest uses similar technologies in their cables.

The wire will be conditioned on the Audiodharma Cable Cooker prior to assembly.

Figure 1. Main ingredients: wire and connectors.

Figure2. I will be using 1/4" WBT quick disconnects, which are gold plated copper.

Figure 3. I found that I could use the WBT disconnects with the narrow tab on the RD0198 tweeters if I gently pry up the middle band on the back of the disconnect and slide the tweeter tab under it.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Looking forward to the results Raife. Cardas Litz wire is very good sounding stuff, IMO. I used it in the DAC I made.

Taken from a recent Audioholics reply regarding "Club Polk" and Polk speakers:

"I'm yet to hear a Polk speaker that merits more than a sentence and 60 seconds discussion."

My response is: If you need 60 seconds to respond in one sentence, you probably should't be evaluating Polk speakers.....

"Green leaves reveal the heart spoken Khatru"- Jon Anderson

"Have A Little Faith! And Everything You'll Face, Will Jump From Out Right On Into Place! Yeah! Take A Little Time! And Everything You'll Find, Will Move From Gloom Right On Into Shine!"- Arthur Lee -

Oh say it ain't so! The one piece of my speakers that I haven't modded is the wiring harnesses. I have a feeling that you're going to come back and say "WOW!!!!!"Good music, a good source, and good power can make SDA's sing. Tubes make them dance.

-

Interesting - I'm a believer in a Litz type configuration. Multiple smaller wires individually insulated and braided.

I use a diy version in my speaker cables: teflon insulated 24 awg solid core copper, 27 pairs braided on the lows (equivalent to 9 awg), 9 pairs braided on the highs (15 awg). The benefits are supposed to be reduced skin effect, reduced smearing from strand jumping of the signal, very low inductance.

Looking forward to your report."Science is suppose to explain observations not dismiss them as impossible" - Norm on AA; 2.3TL's w/sonicaps/mills/jantzen inductors, Gimpod's boards, Lg Solen SDA inductors, RD-0198's, MW's dynamatted, Armaflex speaker gaskets, H-nuts, brass spikes, Cardas CCGR BP's, upgraded IC Cable, Black Hole Damping Sheet strips, interior of cabinets sealed with Loctite Power Grab, AI-1 interface with 1000VA A-L transformer -

Great!! I have been wanting to do this for some time now, I'm looking forward to your findings..

-

Cardas Litz wire is very good sounding stuff, IMO. I used it in the DAC I made.

Even if this doesn't work, I can sleep better knowing that my speakers are full of audiophile approved Cardas wire.:razz:Proud and loyal citizen of the Digital Domain and Solid State Country! -

Too bad it doesn't come in colors other than black and red. Would be good to be able to stick with spec colors. Could always throw a bit of colored shrink tube on the end to indicate white, blue, green, etc., but would look better if the jacket was the correct color....Good music, a good source, and good power can make SDA's sing. Tubes make them dance.

-

You and Roger are like two peas in a pod, Raife.Jay

SDA 2BTL * McCormack DNA 0.5 amp * Oppo BDP-93 * Modded Adcom GDA-600 DAC * Rythmik F8 (x2)

Micro Seiki DQ-50 * Hagerman Cornet 2 Phono * A hodgepodge of cabling * Belkin PF60

Preamp rotation: Krell KSL (SCompRacer recapped) * Manley Shrimp * PS Audio 5.0 -

The Cardas wire is a lower noise design due to the Litz configuration (reduction of strand interaction by insulating individual wire strands)

Cardas wire is a PITA unless you've got a solder pot.Too bad it doesn't come in colors other than black and red.

It use to come in lots of colors, might have to look around a bit tho.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

DarqueKnight wrote: »Even if this doesn't work, I can sleep better knowing that my speakers are full of audiophile approved Cardas wire.:razz:

Or even better Raife, the fact that it's used by Roger Russel! :eek::razz:

:eek::razz:

Taken from a recent Audioholics reply regarding "Club Polk" and Polk speakers:

"I'm yet to hear a Polk speaker that merits more than a sentence and 60 seconds discussion."

My response is: If you need 60 seconds to respond in one sentence, you probably should't be evaluating Polk speakers.....

"Green leaves reveal the heart spoken Khatru"- Jon Anderson

"Have A Little Faith! And Everything You'll Face, Will Jump From Out Right On Into Place! Yeah! Take A Little Time! And Everything You'll Find, Will Move From Gloom Right On Into Shine!"- Arthur Lee -

Cardas wire is a PITA unless you've got a solder pot.

I didn't find it too bad Jesse. I just used my Weller soldering iron. It does take a little patience, but not too bad IMO.It use to come in lots of colors, might have to look around a bit tho.

It really depends on the gauge you are looking for how easy it is to find multiple colors. At 15.5 AWG it may be more difficult. I found smaller gagues in Red, Green, Blue, White, and Black at Sonic Craft a couple years back. All these colors are probably made in 15.5 AWG but as you said Jesse are much harder to find.

Taken from a recent Audioholics reply regarding "Club Polk" and Polk speakers:

"I'm yet to hear a Polk speaker that merits more than a sentence and 60 seconds discussion."

My response is: If you need 60 seconds to respond in one sentence, you probably should't be evaluating Polk speakers.....

"Green leaves reveal the heart spoken Khatru"- Jon Anderson

"Have A Little Faith! And Everything You'll Face, Will Jump From Out Right On Into Place! Yeah! Take A Little Time! And Everything You'll Find, Will Move From Gloom Right On Into Shine!"- Arthur Lee -

DarqueKnight wrote: »Even if this doesn't work, I can sleep better knowing that my speakers are full of audiophile approved Cardas wire.:razz:

I get the feeling you sleep like a baby anyway:cool:

curious to know what you do to the enamel coating on his wire to make your crimp work better or are you tinning the wire before hand? -

nspindel wrote:Too bad it doesn't come in colors other than black and red.

The limited colors didn't bother me as I prefer the conventional colors of red for + and black for -. I am going to color code the ends with acrylic paint according to driver/tweeter number.Cardas wire is a PITA unless you've got a solder pot....curious to know what you do to the enamel coating on his wire to make your crimp work better or are you tinning the wire before hand?

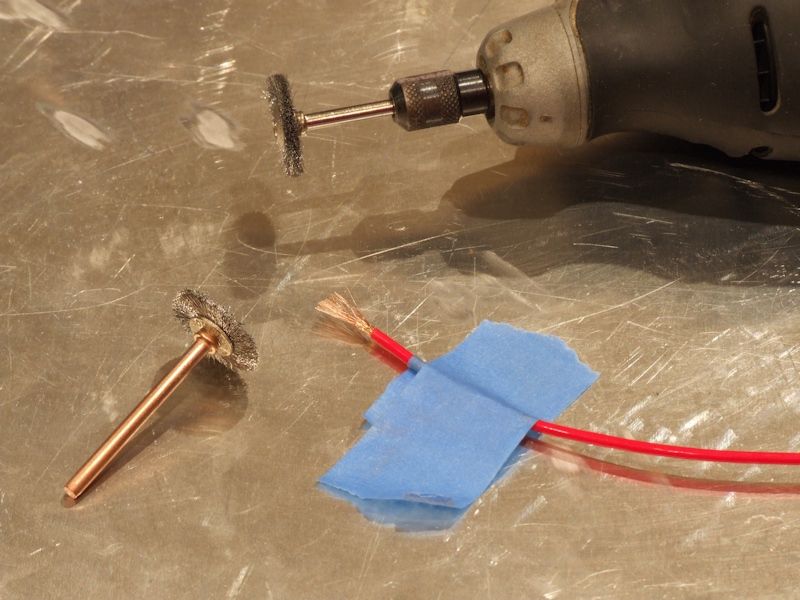

I am using a Dremel with a stainless steel wire wheel (attachment #503) to grind off the annoyingly clear and invisible polyurethane coating. Continuity is confirmed with a multimeter. The wire is rotated 90 degrees and secured in four different orientations so that all sides of a strand get treated.

I am using all crimped connections as they are electrically quieter than soldered connections. All of the grinding and crimping is a tedious process, but I am hoping there will be some audible benefit from the cleaner connections and reduced strand interaction.I get the feeling you sleep like a baby anyway:cool:

I do.:biggrin:Proud and loyal citizen of the Digital Domain and Solid State Country! -

could someone use some sort of liquid stripper? would it just be more gunk in the way? I was just thinking one could strip and wash for good clean metal without all the tedious dremal work on such small areas. I've always liked Cardas items and had very good luck, but the wire i must say been very hesitant about because of what others have told me that used it.

-

DarqueKnight wrote: »The limited colors didn't bother me as I prefer the conventional colors of red for + and black for -. I am going to color code the ends with acrylic paint according to driver/tweeter number.

Ray, Just a thought why not use colored heat shrink tubing, it won't come off and you can use it on the connector barrel to help seal the connection.DarqueKnight wrote: »I am using all crimped connections as they are electrically quieter than soldered connections.

I didn't know that, I guess you do learn something everyday. :cool: I was taught that crimping was done for a good mechanical connection and then soldered for a good electrical connection.

Anyway I'll be very interested in your results as I've still got my 4.1TL project to finish that I have to make up a new wiring loom for and a new set of 1C's to do.“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain -

It use to come in lots of colors, might have to look around a bit tho.

Only thinner gauges. 15.5 is only red and black, at least at soniccraft.Good music, a good source, and good power can make SDA's sing. Tubes make them dance. -

could someone use some sort of liquid stripper? would it just be more gunk in the way? I was just thinking one could strip and wash for good clean metal without all the tedious dremal work on such small areas.

I don't know of any solvent that will dissolve cured polyurethane. If there were such a solvent, cleaning the resulting sticky gunk would be another problem. It seems that, with polyurethane, we are stuck with burning it off with solder or grinding it off.

I just wish the wire coating was colored so that I could visually tell when it was all off!Ray, Just a thought why not use colored heat shrink tubing, it won't come off and you can use it on the connector barrel to help seal the connection.

Painting is quicker and easier.I didn't know that, I guess you do learn something everyday. :cool: I was taught that crimping was done for a good mechanical connection and then soldered for a good electrical connection.

Solder is quick, easy, and convenient, but the metals used are not as conductive as copper...hence the use of silver to improve conductivity. The best electrical connection is a metal-to-metal pressure weld, but this is impractical in many situations.Proud and loyal citizen of the Digital Domain and Solid State Country! -

DarqueKnight wrote: »I don't know of any solvent that will dissolve cured polyurethane. If there were such a solvent, cleaning the resulting sticky gunk would be another problem. It seems that, with polyurethane, we are stuck with burning it off with solder or grinding it off.

I just wish the wire coating was colored so that I could visually tell when it was all off!

How about setting up an oil lamp, removing the glass chimney and burning it off over the flame? Should be easy to control."Science is suppose to explain observations not dismiss them as impossible" - Norm on AA; 2.3TL's w/sonicaps/mills/jantzen inductors, Gimpod's boards, Lg Solen SDA inductors, RD-0198's, MW's dynamatted, Armaflex speaker gaskets, H-nuts, brass spikes, Cardas CCGR BP's, upgraded IC Cable, Black Hole Damping Sheet strips, interior of cabinets sealed with Loctite Power Grab, AI-1 interface with 1000VA A-L transformer -

DarqueKnight wrote: »I am using a Dremel with a stainless steel wire wheel (attachment #503) to grind off the annoyingly clear and invisible polyurethane coating.

I meant to say attachment #530. However, I have replaced attachment #530 (stainless steel brush) with attachment #428 (carbon steel brush). The carbon steel brush works faster and is more appropriate for this type of work. From the Dremel product descriptrions:

428-Carbon Steel Brush - "Remove dirt, rust, and corrosion from most surfaces. Clean electrical connectors and other metal parts, remove buildup from faucets, clean camp stove burners and more."

530-Stainless Stee Brush - "Use on stainless steel, pewter, aluminum, silver and other white metals. Use for cleaning, deburring and surface finishing."

The carbon steel brush is attached to the Dremel. The stainless steel brush is at the lower left. The work

surface is the bottom of an aluminum baking pan.drumminman wrote: »How about setting up an oil lamp, removing the glass chimney and burning it off over the flame? Should be easy to control.

I don't see any smiley's, so I am assuming you are not being facetious. The hair-thin wires easily get red hot and incinerate in an open flame. Even if incineration weren't a problem, you would still have to scrape off the charred polyurethane residue...and soot from the oil.Proud and loyal citizen of the Digital Domain and Solid State Country! -

DarqueKnight wrote: »I don't see any smiley's, so I am assuming you are not being facetious. The hair-thin wires easily get red hot and incinerate in an open flame. Even if incineration weren't a problem, you would still have to scrape off the charred polyurethane residue...and soot from the oil.

Nope, no smiley faces. I was serious. Good points though. I suppose I was thinking solid core, burn it off and make a couple passes with some 0000 steel wool to remove the residue.

OK, carry on "Science is suppose to explain observations not dismiss them as impossible" - Norm on AA; 2.3TL's w/sonicaps/mills/jantzen inductors, Gimpod's boards, Lg Solen SDA inductors, RD-0198's, MW's dynamatted, Armaflex speaker gaskets, H-nuts, brass spikes, Cardas CCGR BP's, upgraded IC Cable, Black Hole Damping Sheet strips, interior of cabinets sealed with Loctite Power Grab, AI-1 interface with 1000VA A-L transformer

"Science is suppose to explain observations not dismiss them as impossible" - Norm on AA; 2.3TL's w/sonicaps/mills/jantzen inductors, Gimpod's boards, Lg Solen SDA inductors, RD-0198's, MW's dynamatted, Armaflex speaker gaskets, H-nuts, brass spikes, Cardas CCGR BP's, upgraded IC Cable, Black Hole Damping Sheet strips, interior of cabinets sealed with Loctite Power Grab, AI-1 interface with 1000VA A-L transformer -

Lasered the plates today. Machine the delrin next week. After seeing Jesse's dreadnought with the NL2's I had to change it. Guess I should have listened to Mike in the first place.. :cheesygrin:

-

After seeing Jesse's dreadnought with the NL2's I had to change it.

I used the NLT4's, a bit beefer all around.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

Great work, as always Larry! Speakon connections are great. No chance of them accidently coming off...

-

I used the NLT4's, a bit beefer all around.

I just saw that. humm wonder if I should order a set before I machine the delrin? I am going to counter bore it so it sets flush to it, and put the stainless flush as you see it.. -

Lasered the plates today. Machine the delrin next week. After seeing Jesse's dreadnought with the NL2's I had to change it. Guess I should have listened to Mike in the first place.. :cheesygrin:

I would suggest a right angle connector, like the Speakon NL4FRX, at the speaker for better strain relief. This would also provide more flexibility in moving the speakers closer to the wall if needed. I don't know if the NL4FRX would provide enough clearance above the top binding posts though.Proud and loyal citizen of the Digital Domain and Solid State Country! -

I could change it and put it on the bottom..:cheesygrin:

-

I've got no issues with strain relief or clearance to the wall. My speakers are 6" off the back wall and there's room to spare.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

DarqueKnight wrote: »I would suggest a right angle connector, like the Speakon NL4FRX, at the speaker for better strain relief. This would also provide more flexibility in moving the speakers closer to the wall if needed. I don't know if the NL4FRX would provide enough clearance above the top binding posts though.

I like this idea! There is room for the big MIT S1 cables, however but a right angle connector would be a nice option.Carl -

I see an issue with the NL4FRX if one is using MIT Shotgun cable. The maximum inside diameter of the shell at the tail end is 14.5mm. The one I used had a maximum inside diameter of 16mm and I had to enlarge it to 21mm, which was at the absolute edge of what it could be enlarged to. The shell also appears to be shorter than the one I used, which may also present an issue.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk