Revox A77 restoration

Comments

-

Here's a photo of the unpainted phenolic pieces showing the holes I drilled for the RCA jacks and the mounting screws. Also the template I drew to figure out where to drill the holes.

-

Here are three examples of the revolution counter, earliest from left to right. The biggest improvement is a reduction of the mechanical noise as the tape is fast forwarded and rewound. Important if you're making a live recording. I've been soaking the one in the middle in WD40 to try and loosen it up, it was completely locked into position. The reset part still isn't working properly so I'll keep on trying.

-

This is the back of the counters and shows the toothed belt I needed to buy from eBay for the one I wanted to use.

-

-

KennethSwauger wrote: »...Bakelite which is a type of phenolic material. The first printed circuit boards, in the '60's, were a paper derived phenolic. Today chances are if you see a tan PCB it will be a phenolic type.

Interesting...especially the tweeters. I do know of Bakelite jewelry and furniture hardware from watching The Antiques Roadshow. Had no idea there was/is the electronics connection.➀Speakers: Polk1.2tl's (Uber Mods) ➁Pre/Amp/DAC: PS Audio PMG Signature Pre, BHK Signature 250, PMG Signature 512 ➂Cables/IC's: MIT S1Bi-Wire/S1 Balanced +Avel Lindberg 1000VA "Dreadnought" ➃Power Conditioner: PS Audio P15 Power Plant ➄Power Cords: Core Power Technologies Gold, DH Labs Power Plus DIY w/Neotech NC-P301 & P311ends ➅Streaming: Roon ROCK on wifi'd NUC, TP-Link WAP, & Uptone EtherREGEN, AfterDark, Emperor Double Crown Clock, Black Modernize LPS⟿Ω☯☥☮⟿🔊♩♪♫♬♩♪♫♬♩♪♫♬ -

Some catching up to do on this project. I finished the reconditioning of the main circuit board assembly, where all of the circuit boards connect. This also holds the support brackets for the VU meters and contains all of the selector switches and potentiometers. There is a sliding bar that attaches to the rotating on/off selector that is responsible for changing the tape speed and setting the proper record/playback EQ. The Nagravox company makes a super well made replacement for this easy-to-break part.

-

Here is a photo of the opposite side of this assembly. I painted the three sockets in the front (headphones and two microphones) and the brackets that attach the VU meters. I also added the central bulb between the two meters, this was added in later versions of the deck.

-

This is a closer photo of the VU meter assembly, the meters were available in either a black or white background.

-

These are the complete set of printed circuit boards for the deck, the input amplifier, record amplifier, bias circuit and playback amplifiers. I've replaced all of the previous tantalum coupling capacitors with WIMA film types, all of the bypass capacitors with Sprague electrolytic versions and all of the trimmer resistors (which tend to become defective) are replaced with sealed versions.

-

Another photo.

-

-

Glad to see the story continue! Amazing work.SystemLuxman L-590AXII Integrated Amplifier|KEF Reference 1 Loudspeakers|PS Audio Directream Jr|Sansui TU-9900 Tuner|TEAC A-6100 RtR|REL T/9X SE Sub

-

The main transistor used throughout the record and playback circuits is the BC107 family of general-purpose low power silicon NPN bipolar junction transistors. The variations are the BC108 and BC109 with B and C suffixes denoting improved noise levels. Here is the schematic for the playback circuitry. The playback head is directly connected to the base of Q801 which has it's output connected to the base of Q802, these are both BC109C transistors.

-

In trying to see if different transistors can change the sound I've begun looking at BC109 devices using my Heathkit curve tracer especially the tests involving dynamic linearity. An ideal trace would have each of the test steps rising quickly from the base horizontal line and forming evenly spaced horizontal lines. Here is a photo of a typical BC109C from an unknown manufacturer.

Note the fairly gradual slopes of the steps and the not exactly parallel traces, kind of like new recruits coming to sloppy attention. Now here is the exact same test with a BC109C made by ATES an Italian subsidiary of the Siemens company.

This looks much more ideal, toes to the line, sharp uniform creases and a sense of pride. I've ordered some new transistors made by a US company Central Semiconductor, based in New Jersey, that specializes in recreating older transistors even the old style metal cap instead of the newer plastic. -

Quite a difference.

-

I've spent some time going over the complete functioning of the deck and sorting out some issues. I ended up removing the complete lower section of the deck and replaced one of the card edge connectors and replacing some of the shielded cables that connect to the two microphone inputs and the single headphone output. There was some less than acceptable soldering done somewhere along the deck's history that finally got on my nerves enough to replace. I also ended up removing and testing all of the transistors on all of the circuit boards and found one that was intermittent causing a dropping of one channel during recording.

Now I could begin testing and calibrating the record and playback functions using both the Revox service manual and Jack Clark's guide. The first step is to calibrate the playback using a test tape and a good meter.

Post edited by SeleniumFalcon on -

Once that is done things such as meter calibration, channel separation, dummy load adjusting, bias level setting can be done. Checking the bias frequency (usually at least four times the upper frequency response capability, in this case 120kHz) and adjusting the record bias and playback bias filters can be done. The bias current is used to erase the tape using the ease head and is mixed with the signal to be recorded to lower distortion and improve high frequency response. The amount of bias depends upon the tape's formulation and a balancing act between noise, distortion and frequency response. You might see the term "over bias" which relates to how much the bias strength is adjusted after the optimum bias point is reached. Here again a signal generator and a good meter is used (a distortion analyzer can be helpful).

-

I just started to look at the deck's record and playback wow and flutter performance using a wow and flutter meter made by Tenma. There are several standards that can be chosen: DIN, NAB and JIS each having a different weighting factor that tries to make the measurement meaningful for actually how the speed errors effect what is heard. I noticed that using LAST on all the stationary parts (heads and guides) reduced NAB wow and flutter by 50%, but didn't seem to change the DIN measurement. I'm going to see if changing the capstan roller's pressure effects the wow and flutter.

-

I'm using SM911 tape for testing.

-

I had to figure out a problem yesterday, when the tape is placed in stop mode the brakes should engage and cause the reel tables to stop. This was only intermittently happening letting the reels continue to turn, not a good thing. I had fiddled with the two small "C" clips that hold two brake actuating arms onto the brake plate and maybe the clips were too tight against the arm pivots. I removed the clips and sanded them to make sure there weren't any rough spots that would cause the arms to bind. I oiled the posts the arms rotate on and made sure the arms could pivot. This seemed to work but it started to happen again. There could be lots of causes, the relays could be the problem, not removing the DC voltage to the brake solenoid and letting the brake arms stay released. Or, the buttons that control tape motion could be losing contact.

To try and figure out where the problem starts I looked at the 26VDC that activates the brake release solenoid and saw that when play was pressed it was present at the solenoid's terminals.

-

Then I checked to see that the voltage was dropped when stop was selected.

-

This meant that the problem was something mechanical that wasn't letting the solenoid's arm pull out away from the solenoid and allow the brake bands to contact the platter hubs and stop the reel tables. I removed the spring that is supposed to pull the arm back after the voltage drops and it looked okay. When I got the new brake bands it came with a new spring and maybe it wasn't strong enough to pull the solenoid arm back? So I compared it to the spring from another deck and it seemed to have about the same tension. I thought about removing a small amount of the spring's length to increase the tension, but that seemed a bit crude. Then I thought about repositioning the solenoid itself further away from the rest position and giving it more tension with the pulled spring. That worked, using the two screws I could very slightly reposition the solenoid and now the brakes worked fine. Normally in a standard overhaul of an A77 it wouldn't be necessary to completely take everything apart so the brake system wouldn't need to be adjusted. Most of the time just cleaning the brakes would be all that's needed.

-

Wonderful precise "WORK" and terrific pictures."Sometimes you have to look to the past to understand where you are going in the future"Harry / Marietta GA

-

Ken,

It's a shame your name was removed from the beginning of this thread and all other posts.

Why couldn't Polk put a new name instead of deleted user?"Sometimes you have to look to the past to understand where you are going in the future"Harry / Marietta GA -

I'm just glad people find the subject interesting enough to read it. That's very gratifying considering it's such an older piece of equipment. Maybe it can help someone in the future to restore another one?

-

Holy Cow.

My expertise ends at loading a reel and pushing the play button.

Tell the truth guys, your REALLY building some kind of funky flux capacitors. -

SeleniumFalcon wrote: »I'm just glad people find the subject interesting enough to read it. That's very gratifying considering it's such an older piece of equipment. Maybe it can help someone in the future to restore another one?

I find this fascinating. And gives me insights into the functions of my own deck (a TEAC).SystemLuxman L-590AXII Integrated Amplifier|KEF Reference 1 Loudspeakers|PS Audio Directream Jr|Sansui TU-9900 Tuner|TEAC A-6100 RtR|REL T/9X SE Sub -

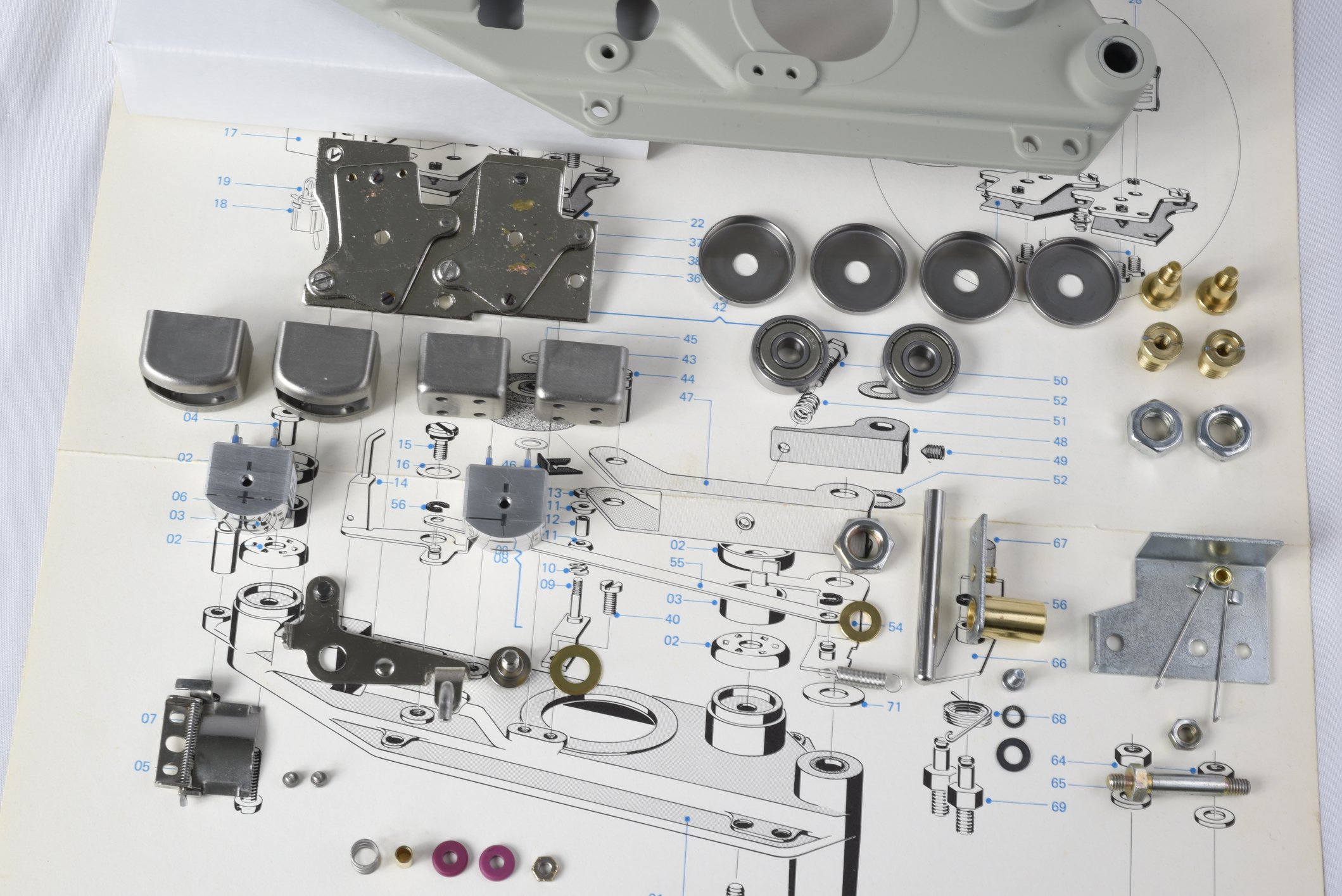

The next step in this project is to replace the original record and playback heads with new versions. This involves completely disassembling the head block assembly and getting everything looking as new as possible. Both of these heads are double shielded, two tight fitting metal shells hold both heads and a small "trap door" shields the playback head when tape play begins. After lots of Q-tips and Flitz I've managed to get all the parts, some very small, looking fairly good and can now start building up the block.

-

I've reassembled the head assembly, trying to get things aligned as much as possible by eye. Now I have to wait for the Cardas tone arm cable and braided shielding so I can attach wires to the record and playback heads. Then swap the new head block for the old one and begin the alignment process.

-

That's gorgeous. Looks brand new!➀Speakers: Polk1.2tl's (Uber Mods) ➁Pre/Amp/DAC: PS Audio PMG Signature Pre, BHK Signature 250, PMG Signature 512 ➂Cables/IC's: MIT S1Bi-Wire/S1 Balanced +Avel Lindberg 1000VA "Dreadnought" ➃Power Conditioner: PS Audio P15 Power Plant ➄Power Cords: Core Power Technologies Gold, DH Labs Power Plus DIY w/Neotech NC-P301 & P311ends ➅Streaming: Roon ROCK on wifi'd NUC, TP-Link WAP, & Uptone EtherREGEN, AfterDark, Emperor Double Crown Clock, Black Modernize LPS⟿Ω☯☥☮⟿🔊♩♪♫♬♩♪♫♬♩♪♫♬