Air Core Inductor falls off crossover during shipping

Comments

-

god luck Drew.. as a man who own a soldering iron but sucks at it, I understand!

just don't burn yourself! you only do that once I promise

And it's best not to solder wearing shorts. You only do that once, too. Maybe twice if you're really thick.

As Doc Mark mentions, it's a handy skeel. I suck less at it, but still suck, and it causes me a measure of performance anxiety, but it's kinda fun and rewarding when you fix something. After you try and successfully work a security Torx set, you're probably ready to move up to apprentice soldering.Post edited by msg onI disabled signatures. -

Disregard

-

god luck Drew.. as a man who own a soldering iron but sucks at it, I understand!

just don't burn yourself! you only do that once I promise

And it's best not to solder wearing shorts. You only do that once, too. Maybe twice if you're really thick.

As Doc Mark mentions, it's a handy skeel. I suck less at it, but still suck, and it causes me a measure of performance anxiety, but it's kinda fun and rewarding when you fix something. After you try a successfully work a security Torx set, you're probably ready to move up to apprentice soldering.

Indeed. Baby steps.

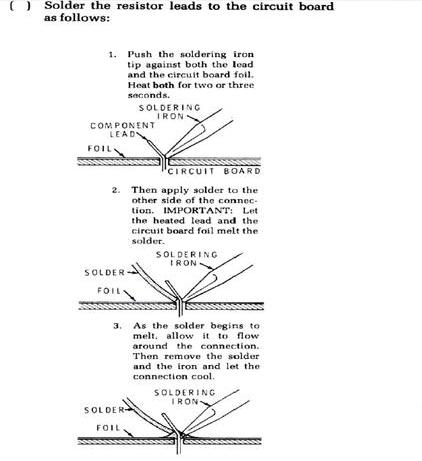

heathkit howtosolder by Mark Hardy, on Flickr

heathkit howtosolder by Mark Hardy, on Flickr eico solder joints by Mark Hardy, on Flickr

eico solder joints by Mark Hardy, on Flickr

I am sure there are video tutorials on YT and whatnot.

Get a good soldering iron or (better yet) temp-controlled station (used is never a bad idea; electronics surplus places can be a good resource for a pro-quality workstation at a reasonable price).

-

Definitely worth the effort Drew. Those are beautiful speaks btw.

Glad the seller is willing to work with you. -

Not really the sellers fault though. Classic example of the shipping company dropping a package flat on it's side. At least that loose hunk of copper didn't wipe out the woofer.

-

Don't take that to mean I'm not rooting for Drew. Those are some really nice speakers.

-

ATC already got back to me regarding next steps in their repair/troubleshooting process. Fast response and service! I've sent them over some photos and the serial numbers to determine the exact model of these.

They've also put me in touch with their US distributor who can assist with repairs! So far so good.

My security torx set arrives later this week hopefully, so I can get at that crossover and figure out what all needs to be done with it. -

Let's continue to talk about ATC speakers while we wait. I just found this cool article about their drivers and speaker design: http://www.acousticfrontiers.com/atc-speakers-technology/

-

ATC Speakers have been my #1 want to hear speakers for a long time...

why do so many musicians have then in their studio's or home (or so I've read)2 ch- Polk CRS+ * Vincent SA-31MK Preamp * Vincent Sp-331 Amp * Marantz SA8005 SACD * Project Xperience Classic TT * Sumiko Blue Point #2 MC cartridge

HT - Polk 703's * NAD T-758 * Adcom 5503 * Oppo 103 * Samsung 60" series 8 LCD -

I've been intrigued by these

https://www.musicdirect.com/speakers/atc-scm40-v2-tower-speakers-cherry-demo

I'll probably never own a pair, but I would certainly like to hear them one day.

-

With the help of my security torx set and right angle screw driver which turned out to be invaluable, I disassembled the speaker tonight.

Cheap harbor freight/eBay tools:

After removing the three security torx screws holding in the silver tweeter waveguide, I slowly and carefully lifted the front baffle. When I did, i realized the baffle was in contact with the wires that were connected to the tweeter and the top of the tweeter lifted off as well with it. The bottom/magnet part is adhered to the cabinet somehow, maybe screwed in from behind. I've illustrated what I mean here:

There's only one way to remove the baffle, by lifting it straight up, and it wasn't clear to me that the tweeter's leads were in contact with it. I don't really know how I could have prevented this, and I'm not sure if it's by design. So, I might be needing a new tweeter as well. But if you look at the way the faston connectors get recessed into the holes in the cabinet, I'm not sure of any other way you'd be able to get a good grip/leverage on them in order to connect or disconnect them. Anyway, I've reached out to ATC for clarification on this.

As I made my way into the cabinet after removing the woofer, I think it's worth mentioning that the woofer is connected using spring loaded banana plugs! Very nice:

Speaking of the woofer, it's massive and uses a huge magnet structure, check it out:

Finally, getting to the crossover we can see that the heavy inductor fell off and partially unraveled, but that it's ends are still firmly soldered to the PCB. Additionally, looking at the lower left hand side of the crossover, we can see that the action of it falling off has severed the positive wire connection to the woofer. Guess that explains why I didn't hear anything at all from the woofer.

I hardly heard anything from the tweeter either. Is it possible that the violent action of the inductor falling off and moving around inside the cabinet also pulled/shocked the wire that was running to the tweeter, and that's why it's now separated and hardly making any sound? Just a thought, might be off base.

Also, @F1nut, Bennic caps!!!

I've emailed the photos to ATC and will let you know what they say.

-

Also, @F1nut, Bennic caps!!!

UghPolitical Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

-

ooooh, wait -- need to disengage Snarky Marky mode!

<ctrl-s><crtrl-o>

There, that's better!

Let's see.

I imagine the tweeter is glued in. Not uncommon with those smaller domes; often they're designed for press fit installation.

I am not a fan of PCB XOs* -- they're not very rugged, and they use - for better or worse - thin, flat (tho' perhaps broad) copper traces for the signal. The fragility of the traces can be an issue. OK, that wasn't very helpful

Constructively, I would say trace out all of the wiring of the circuit, including the traces on the PCB, and look for either lifted traces (fairly unlikely) or (more likely) cracked solder joints. Check for shorts, too. Look closely, as it could take only a couple strands of the zip cord to foul things up.

Look at the connections to the woofer and tweeter, too -- as an aside banana plugs seems like an odd/risky choice for an internal connector in a loudspeaker, since they can come loose.

Let's see... it probably wouldnt' hurt to check that big, loose inductor for continuity with an ohm meter (DMM or just a little multitester should suffice); resistance from end to end won't be zero, of course, but it should be low (several ohms, maybe low teens of ohms or so) -- it certainly shouldn't be high.

Nothing strikes me as obviously out of whack.

One other thought, I guess -- check the condition of the coil's wire at those bends near the XO board. They could be cracked.

Did "we" tell you how to mitigate (remove) the enamel (or varnish) insulation on the inductor leads if a field repair is attempted? A soldering iron will locally burn off the enamel to permit soldering of the ends of the inductor. Alternatively, fine abrasive (sandpaper, e.g.) can be used to remove it.

Sorry, looks like the Snarky Marky mode toggled itself on a couple of times while I was typing! I still hope there are a couple of useful tidbits mixed in.

I still hope there are a couple of useful tidbits mixed in.

Probably, for @Clipdat, a pro repair on that single loudspeaker is going to be the best way forward.

The waiting is the hardest part.

______________

* OK, I am not a fan of PCBs in general (FWIW) -- although in a complex XO like the new Polk L800 they make sense from an assembly and aesthetic standpoint. -

I'm with Mark

Trace the circuit, looks simple, order 100 bucks in nice caps and resistors, reuse in the inductors and rebuild it ptp- Not Tom ::::::: Any system can play Diana Krall. Only the best can play Limp Bizkit. -

Literally the cheapest sand cast resistors and the second cheapest capacitor option (NPE's would've been absolute rock bottom) in that XO.

The Bennics are a big step up from NPEs when redoing, say, a 1960s KLH Six (BTDT, as they say) -- but, in the great scheme of things, the Bennics impart a zingy kind of brightness when used with good (extended) tweeters that works against all of my dominant ear-gouger sensitivity genes.

I guess the converse of that is that the loudspeakers will sound different with a change or capacitors -- but, if there's no treble now, it's not likely to strike @clipdat as worse-sounding

Oh, one other thing -- it would also be worthwhile to check the DC resistance of both the woofer and tweeter VCs in the 'bad' loudspeaker. Cannot have too much data when troubleshooting, IMO.

-

Here is what ATC said:

"From a disassembly point of view that all looks fine, this earlier version is more fiddly to service than the current one, because of the baffle, as you have found out. The tweeter coming apart is normal. The tweeter cone/coil/magnet/assembly should stay with the cabinet, the flange stays with the baffle. You will need to remove the crimps next. Be very careful removing the crimps, and note polarity, of course. White pos, Yellow neg. Needle nose pliers are probably the right tool to use here.

Next, I would pop the magnet out, it will push up from behind, as it is just sitting in its gasket. Then carefully drop the cone/coil back on to the magnet, it will self-locate, but we must be careful of dust/debris getting stuck in the gap, remember that there is ferro fluid in the gap.

When you come to reconnect the tweeter, feed the wires though the baffle first, reconnect, and then drop it very carefully back into the hole in the baffle. When you replace the baffle, it will all reseal as there is a gasket behind it.

As regards the choke, that looks pretty straightforward, if you have the soldering skills. I would remove the crossover completely, and desolder the choke completely, then rewind the tails back into the body of the choke. You can then reseat it on to the PCB, and secure with silicone sealant, (bathroom sealant) and then secure it properly with two cable ties.

You also need to reterminate the speaker connection for the LF, of course. Then you can test it with the drivers, as it stands, and if all is OK, you can then reassemble it all properly." -

I would use hot melt glue and/or 3M high bond two sided tape not silicone Drew... But that is just me

-

Yeah, looks like the inductor acted as a wrecking ball in there, breaking one of the woofer cables. I wonder if having the inductor now in such close proximity to the tweeter cables creates an EMI issue of sorts...a magnetic field around those cables can't be good. "This may not matter to you, but it does to me for various reasons, many of them illogical or irrational, but the vinyl hobby is not really logical or rational..." - member on Vinyl Engine

"This may not matter to you, but it does to me for various reasons, many of them illogical or irrational, but the vinyl hobby is not really logical or rational..." - member on Vinyl Engine

"Sometimes I do what I want to do. The rest of the time, I do what I have to." - Cicero, in Gladiator

Regarding collectibles: "It's not who gets it. It's who gets stuck with it." - Jimmy Fallon -

I'm with Mark

Trace the circuit, looks simple, order 100 bucks in nice caps and resistors, reuse in the inductors and rebuild it ptp

Rebuilding/upgrading both crossovers crossed my mind, but I already spent $900 on these speakers so I'm not that eager to start dropping more money on them.

Plus there's the fact that I'm completely out of my element here and don't even have the equipment or skill to perform the repair as described above by ATC. My friend @joecoulson offered to do it for me if I ship the crossover to him, so that's likely what I will be doing. -

Excellent, need to talk Joe into doing his to!- Not Tom ::::::: Any system can play Diana Krall. Only the best can play Limp Bizkit.

-

I would use hot melt glue and/or 3M high bond two sided tape not silicone Drew... But that is just me

3M VHB tape and zip ties are the ticket. Hot glue doesn't have enough sheer strength for an inductor that heavy and neither does silicone, which shouldn't be used period.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

Sounds like the mfgr. gave forthright information; kudos to them!

I do agree with @F1nut (imagine that?!) -- although I was gonna say that if you use RTV (silicone), be sure to use neutral cure (the stuff made for contstructing all-glass aquaria) and not the ordinary acid cure stuff (which uses acetic acid as the catalyst for polymerization). The acetic acid is around forever and is quite corrosive.

That being said -- given the heft of the coil, something with more gumption than RTV is gonna be a 'best practice'.

I don't think the choke would have such a huge inductive proximity effect on the tweeter or the signal going to it, but who knows? It's a testable hypothesis, and the fields around inductors can be substantial at close range.

Nice that @joecoulson will wield the iron for you, @Clipdat!

You gonna re-wire that bad boy while you're at it?

I don't really believe in wire -- but the stuff that's in there is dismal even by my "liberal" standards.

-

What's wrong with the factory wiring? Looks like typical 14ga copper wiring, even has some sort of subtle internal braid pattern under the insulation.

-

If you want new wiring send it and I’ll do it. Would be easy enough. Happy to help.

-

Awesome. Well if anyone wants to see these with upgraded wiring, feel free to send the wires to Joe to install!

-

joecoulson wrote: »If you want new wiring send it and I’ll do it. Would be easy enough. Happy to help.

Kudos to you for helping a brother out Joe! Audio: Polk S15 * Polk S35 * Polk S10 * SVS SB-1000 Pro

Audio: Polk S15 * Polk S35 * Polk S10 * SVS SB-1000 Pro

HT: Samsung QN90B * Marantz NR1510 * Panasonic DMP-BDT220 * Roku Ultra LT * APC H10 -

How much wire do you need?

I might have some supra rondo to throw in the mail- Not Tom ::::::: Any system can play Diana Krall. Only the best can play Limp Bizkit. -

Haha! I appreciate the generous offer Trey, but I was just kidding. I'd have to pull the other one and give it the equal treatment to do this "right". Just not sure I'm looking to put more money into these right now, as tempting as it is to get rid of the Bennic caps.

-

Very generous of you Trey, as Drew said, but I have a technical question. Do you separate the two conductors and use separately in these applications, or twist the ends together in pairs?How much wire do you need?

I might have some supra rondo to throw in the mail"This may not matter to you, but it does to me for various reasons, many of them illogical or irrational, but the vinyl hobby is not really logical or rational..." - member on Vinyl Engine

"Sometimes I do what I want to do. The rest of the time, I do what I have to." - Cicero, in Gladiator

Regarding collectibles: "It's not who gets it. It's who gets stuck with it." - Jimmy Fallon