A electronics/physics question about wire?

gimpod

Posts: 1,793

in Electronics

Before any of you go "Oh no not another wire thread", I think this is more an electronics/physics question and not just audio related.

Here's the question: What causes small gauge wire (I think 24 gauge and smaller) solid and stranded turn really stiff and break over time with use (less than a year). Any Ideas, I've had this happen with the last 3 hand control's for my hospital bed and with cheap small headphones.

Here's the question: What causes small gauge wire (I think 24 gauge and smaller) solid and stranded turn really stiff and break over time with use (less than a year). Any Ideas, I've had this happen with the last 3 hand control's for my hospital bed and with cheap small headphones.

“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain

Comments

-

My guess is...air. Maybe they aren't sealed well enough.

The wire itself breaks or the plastic coating gets brittle and breaks ?HT SYSTEM-

Sony 850c 4k

Pioneer elite vhx 21

Sony 4k BRP

SVS SB-2000

Polk Sig. 20's

Polk FX500 surrounds

Cables-

Acoustic zen Satori speaker cables

Acoustic zen Matrix 2 IC's

Wireworld eclipse 7 ic's

Audio metallurgy ga-o digital cable

Kitchen

Sonos zp90

Grant Fidelity tube dac

B&k 1420

lsi 9's -

The wire. It looks like it's sealed really good, I'd have to cut the controller open to see where the wire's broken. I think it's broke where the wire go's into the controller. If you hold it just right it works but move it a little and it quits working.

“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain -

If you hold it just right it works but move it a little and it quits working.

Sounds like the ol bread tie. If you move it back and forth a little she'll break at least that is what it sounds like to me. Thin enough to not take much back and forth movement.

-

wire breaks when repeatedly flexed Indeed, that's how I was taught to break off a length of solder by my father long, long ago :- ) Just wiggle it back and forth, and it breaks.

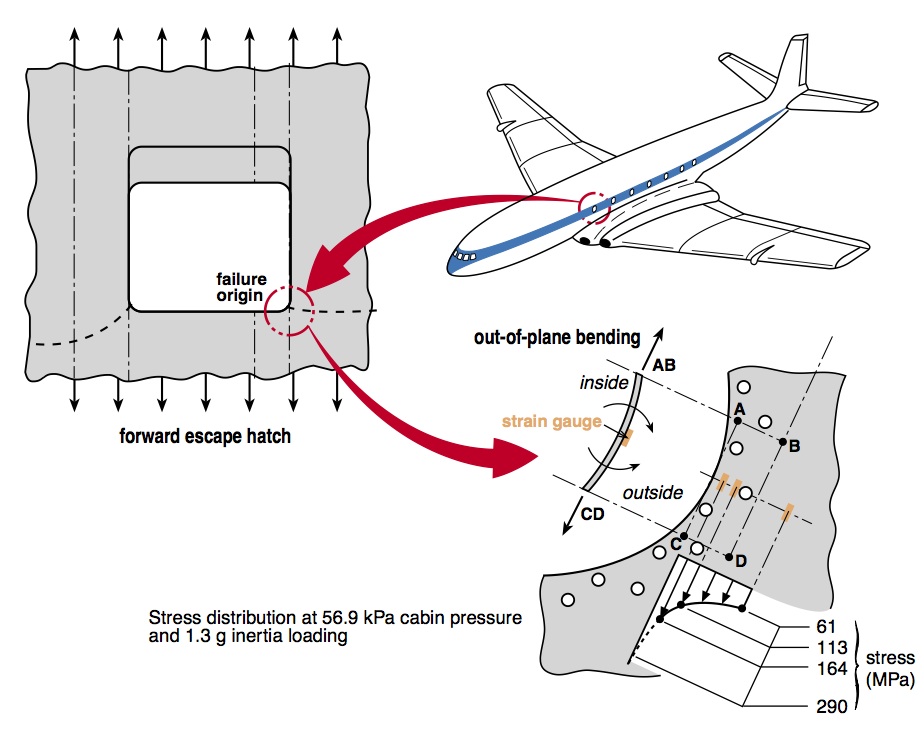

That's what caused the original DeHavilland Comet jet liners to plummet from the sky -- metal fatigue (stress cracks) caused by strain of pressurization/depressurization cycles (flexing) at the stress points caused by its (fairly large) square passenger windows. oops.

http://www.uh.edu/engines/epi112.htm

https://en.wikipedia.org/wiki/BOAC_Flight_781

Not electronics, it's physics. Metal fatigue.

https://en.wikipedia.org/wiki/Fatigue_(material)

My belief/understanding has been that the bending induces (or deforms and reforms) microcrystalline regions in the area being stressed, which somehow potentiates the ultimate failure of the (in this case) wire. That may not be accurate, but it's comprehensible. :-/

Dammit, Jim, I'm a biochemist not a metallurgist! ;- )

-

I think you guys are missing the point. I know about "Metal Fatigue" all to well I've broken the back of just about every wheelchair I've owned.

The wire starts out being very flexible but over time (about 6 months or so) it starts to turn really stiff and then breaks. It's not the sheathing it doesn't show any signs of cracking or breaking, it's the wire.

I think it's cheap wire and it's gauge is to small for it's use. I think it's the voltage and/or amperage that's causing the wire in the cable to change it's properties.

It's diameter is about 2/3's that 'of a cat 5/6 cable with 12 wires. I'd just say screw it and make one myself but it uses what looks like a 8-conductor RJ-45 modular connector that has 12 conductors. I think it's a custom made connector cause I've not been able to find one. If I could get at the connectors on the bed I could change them but that would most likely void the warranty.

I just wish company's would make things that last. I guess I'll have to get the VA to order a new one again but that is such a PITA.“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain -

Everything in your post that I read sounds like metal fatigue to me, so I'm out.

Sorry.

-

mhardy6647 wrote: »Everything in your post that I read sounds like metal fatigue to me, so I'm out.

Sorry.

@mhardy6647 Don't be sorry your right it is metal fatigue that's causing the wire to break. The question I'm asking is what's causing the wire to get so stiff that metal fatigue becomes a problem. When it's new the wire is as flexible as say the wire on a good set of headphones and then gets stiff and breaks.

BTW: I had the same problem years ago when I would get those cheapo $3 - $5 headphones for my T.V. from Rat Shack (Long before HD and Widescreen T.V.s)“The two most important days in your life are the day you are born and the day you find out why.” ~ Mark Twain -

It sounds like it is missing a strain relief as it exits the casing. This could be remedied with some heat shrink at the exit point on the next replacement of the cable. Since this is being used in the healthcare area instead of the retail market, there isn't a return rate being tracked to cause a recall to be issued.HT Optoma HD25 LV on 80" DIY Screen, Anthem MRX 300 Receiver, Pioneer Elite BDP 51FD Polk CS350LS, Polk SDA1C, Polk FX300, Polk RT55, Dual EBS Adire Shiva 320watt tuned to 17hz, ICs-DIY Twisted Prs, Speaker-Raymond Cable

2 Channel Thorens TD 318 Grado ZF1, SACD/CD Marantz 8260, Soundstream/Krell DAC1, Audio Mirror PP1, Odyssey Stratos, ADS L-1290, ICs-DIY Twisted , Speaker-Raymond Cable -

mhardy6647 wrote: »Everything in your post that I read sounds like metal fatigue to me, so I'm out.

Sorry.

@mhardy6647 Don't be sorry your right it is metal fatigue that's causing the wire to break. The question I'm asking is what's causing the wire to get so stiff that metal fatigue becomes a problem. When it's new the wire is as flexible as say the wire on a good set of headphones and then gets stiff and breaks.

BTW: I had the same problem years ago when I would get those cheapo $3 - $5 headphones for my T.V. from Rat Shack (Long before HD and Widescreen T.V.s)

Well I think it is the same issue as when you resize brass too many times. I think they call it "work hardening" or something like that. It simply becomes brittle from repeated flexing, expanding and contracting etc. Annealing (heating it) the brass can extend its life. But I guess you cant take a torch to your wires. -

Coild somply be something with the manufacturing process. In this instance that's what I would lean towards.

Impurities in the metal, bad temperature control in the extruded, or fluctuating temperature/humidity in the processing area. Unusual or custom connecter would mean a specific manufacturer.

-

Yes, it's "work hardening". Soft copper wire when repeatedly flexed turns into hard copper wire.

-

Gotcha Tony,

I'm assuming it always breaks at the point of the most flex, at the bottom of the controller ? Is it possible to put something harder over the wire like harder plastic making it more stiff and not as flexible ? It would also have to attaché to the bottom of the controller....super glue, small screws, etc.

Another option is to affix the controller to something a tad bigger and solid, maybe on a stand next to the bed or attached to the bed itself, so the wire stays in one position and isn't always flopping around. Don't know if that would work for you in your situation though.HT SYSTEM-

Sony 850c 4k

Pioneer elite vhx 21

Sony 4k BRP

SVS SB-2000

Polk Sig. 20's

Polk FX500 surrounds

Cables-

Acoustic zen Satori speaker cables

Acoustic zen Matrix 2 IC's

Wireworld eclipse 7 ic's

Audio metallurgy ga-o digital cable

Kitchen

Sonos zp90

Grant Fidelity tube dac

B&k 1420

lsi 9's -

How about a strain relief coil at the base of the controller where the lead wire is attached?

-

dunno if this helps but I seen one of these "life hacks" or something where you thread a spring from a "bic click" type of pen onto the cable to keep it from flexing too much at the junction Maybe what lightman is talking about?

-

http://www.oushengnb.com/strain-relief/xx019-1091.html

A few examples of what might work.

Just need cable diameters. I've used them on a several jobsite temp power boards. Lots of SO cords feeding sub panels many floors vertical. They stand up to some serious abuse. Have a look at the controller pad and where the wire exits. Might help stop what's happening to the cable. See if the VA will chip in for it.

Just saw that it's about the size of CAT5 cable. They should have something along that size.

This is just one of several suppliers in the industry.

Good luck and let us know if we can help.

Salute! Good veteran! Thumbs up!

-

When I was working w/ an electrician he used these strain relief devices he affectionately called Chinese handcuffs. Of course these are for more industrial use. Why yours failed is just over use and it found it's weak point and breaks. In the cheapo headphones the wire used is hair thin and for a bed /nurse caller just the weight of the thing being slung over,dropped, wrapped around the bed rail over thousands of times, again finds the weak spot and breaks.

https://www.fruitridgetools.com/electrical/cable-grips/leviton-industrial-straight-male-strain-relief-liquid-tight-cable-cord-grip-3-4-npt-l7903/

http://www.mcmelectronics.com/product/21-14335?utm_medium=cse&utm_source=bing&utm_campaign=bing2chl- Adcom GFA- 555-Onkyo P-3150v pre/amp- JVC-QL-A200 tt- Denon 1940 ci cdp- Adcom GFS-6 -Modded '87 SDA 2Bs - Dynamat Ext.- BH-5- X-Overs VR-3, RDO-194 tweeters, Larry's Rings, Speakon/Neutrik I/C- Cherry stain tops Advent Maestros,Ohm model E

H/T- Toshiba au40" flat- Yamaha RX- V665 avr- YSD-11 Dock- I-Pod- Klipsch #400HD Speaker set-

Bdrm- Nikko 6065 receiver- JBL -G-200s--Pioneer 305 headphones--Sony CE375-5 disc -

I believe I have some 24 gauge clear-coat wire around here that is 15 years old and has been in a ball for most of that time. It seems perfectly flexible no hardening, no splitting, none of the problems mentioned above.

So the question! Is unused wire immune to these effects or is this unusual?Currently orbiting Bowie's Blackstar.!

Polk Lsi-7s, Def Tech 8" sub, HK 3490, HK HD 990 (CDP/DAC), AKG Q701s

[sig. changed on a monthly basis as I rotate in and out of my stash] -

the hardening comes with (repeated) mechanical deformation, a single round (i.e., coiling it up once) will cause some stress fracture, but not enough (usually) to contribute to (shall we say) macroscopic stiffening nor failure.

So... yeah, the advice re: strain reliefs given to the OP by (pretty much) everyone so far seems prudent.

:- )