Bad SDA box design?

Comments

-

The guys who added the Blackhole5 could you elaborate alittle more on what you did?

And has anyone ever replaced all of the existing dampening material in an SDA with some type of aftermarket material? -

Mr. Bubbles wrote: »The original SRS's were very rigid due to the internal bracing but were not open internally and the passives suffer somewhat as compared to the 1.2's and 1.2TL's. But the latter versions though open, are not nearly as rigid, allowing additional resonances from the cabinet. This was addressed somewhat by the grooving of the cabinet panels internally to break up waves in the panels themselves, but his only made the cabinets less rigid. This design would be closer to optimal with much thicker cabinet walls and a completely open internal volume (except for absorbent damping material behind the drivers). But imagine how heavy these would have been and the cost to have shipped them even during production years. It all goes back to the give and take.That's not correct. The SRS cabinet is not as rigid as the 1.2/1.2TL and the bass repsonse from the SRS is sloppy by comparison.Mr. Bubbles wrote: »I completely disagree with this. I own both the SRS and the 1.2TL and the latter version does NOT have a more rigid cabinet. In fact it has less bracing than the SRS. It does have grooves cut into the panel boards internally to break up panel resonance. It is the more open cabinet in the latter version that helps the bass response.

I also own the SDA SRS and the SDA SRS 1.2TL. Here are some things to consider:

1. Greater cabinet wall rigidity can be achieved either by using thicker cabinet walls of the same material or cabinet walls of the same size with a denser more rigid material. The SRS cabinets are made of particle board. The 1.2TL cabinets are made of MDF. MDF is a more dense and rigid material than particle board.

2. The SRS cabinets use extensive internal bracing. The 1.2TL cabinet bracing consists mainly of five two-inch wide MDF strips running front to back in the upper section of the cabinet. The SRS cabinets use far more internal material, yet the SRS cabinet only weighs two pounds more than the essentially open monocoque design 1.2TL cabinets (182 pounds for the SRS, 180 pounds for the 1.2TL). In order for the 1.2TL cabinets to come this close to the weight of the SRS cabinets while using far less internal material, they would have to me made of a denser, heavier weight material.

3. Polk said that one of the design goals going from the SRS to the SRS 1.2 was the reduction of cabinet resonance (the 1.2 and 1.2TL cabinets are identical). This was achieved with a denser, more rigid cabinet material with internal grooving to break up standing waves.

Figure 1. SDA SRS (left) and SDA SRS 1.2TL with side panel off.

Figure 2. SDA SRS closeup of exposed particle board cabinet panel.

Figure 3. SDA SRS 1.2TL closeup of exposed MDF cabinet panel.Proud and loyal citizen of the Digital Domain and Solid State Country! -

DarqueKnight wrote: »I also own the SDA SRS and the SDA SRS 1.2TL. Here are some things to consider:

1. Greater cabinet wall rigidity can be achieved either by using thicker cabinet walls of the same material or cabinet walls of the same size with a denser more rigid material. The SRS cabinets are made of particle board. The 1.2TL cabinets are made of MDF. MDF is a more dense and rigid material than particle board.

2. The SRS cabinets use extensive internal bracing. The 1.2TL cabinet bracing consists mainly of five two-inch wide MDF strips running front to back in the upper section of the cabinet. The SRS cabinets use far more internal material, yet the SRS cabinet only weighs two pounds more than the essentially open monocoque design 1.2TL cabinets (182 pounds for the SRS, 180 pounds for the 1.2TL). In order for the 1.2TL cabinets to come this close to the weight of the SRS cabinets while using far less internal material, they would have to me made of a denser, heavier weight material.

3. Polk said that one of the design goals going from the SRS to the SRS 1.2 was the reduction of cabinet resonance (the 1.2 and 1.2TL cabinets are identical). This was achieved with a denser, more rigid cabinet material with internal grooving to break up standing waves.

Figure 1. SDA SRS (left) and SDA SRS 1.2TL with side panel off.

Figure 2. SDA SRS closeup of exposed particle board cabinet panel.

Figure 3. SDA SRS 1.2TL closeup of exposed MDF cabinet panel.

I apologize that all of this seems to have gotten off of the OP's subject somewhat. I agree with all of this. materials definitely have to be taken into consideration as well as bracing as do the internal grooves. Though the grooves have no strengthening effect on rigidity but actually the opposite.

cabinet (panel) resonance does indeed appear to be less in the TL's vs the SRS's. However cabinet flex would be another issue. The materials of these 2 cabinets are indeed different and the TL uses the better denser material. however it is still not up to par with modern MDF. But (at least on my cabinets) the material is more of what i would consider a denser particle board.

I hope no one gets me wrong, i think from a mass merchandising/ design standpoint they did a great job. From a cost is no option standpoint (which is naturally not the case) improvements could have easily been made. I have more issues with their production quality of the cabinets.

The cabinet designs are good and definitely improved as the models progressed, but trade offs are always made. As hobbyists we can always improve on those things considered to be trade offs ourselves. Very much like the crossovers can be improved, the cabinets can be as well, but not in relation to the original question posted by the OP.If con is the opposite of pro, is Congress the opposite of Progress?!

Monitor 5Jr, Monitor 5, RTA12, RTA 15TL, SDA 2A, 1c, SRS 2, 1.2TL, CRS, Atrium. -

kidglove13 wrote: »The guys who added the Blackhole5 could you elaborate alittle more on what you did?

And has anyone ever replaced all of the existing dampening material in an SDA with some type of aftermarket material?

For my review go here: http://www.polkaudio.com/forums/showthread.php?128159-Black-Hole&highlight=drumminman

I used BH5 in addition to the original poly stuffing, which is recommended."Science is suppose to explain observations not dismiss them as impossible" - Norm on AA; 2.3TL's w/sonicaps/mills/jantzen inductors, Gimpod's boards, Lg Solen SDA inductors, RD-0198's, MW's dynamatted, Armaflex speaker gaskets, H-nuts, brass spikes, Cardas CCGR BP's, upgraded IC Cable, Black Hole Damping Sheet strips, interior of cabinets sealed with Loctite Power Grab, AI-1 interface with 1000VA A-L transformer -

Mr. Bubbles wrote: »I apologize that all of this seems to have gotten off of the OP's subject somewhat. I agree with all of this. materials definitely have to be taken into consideration as well as bracing as do the internal grooves. Though the grooves have no strengthening effect on rigidity but actually the opposite.

Your comment piqued my curiosity regarding the effect that the grooving might have on the stability of the cabinet panels. Grooves are only on the side and rear panels of my SDA SRS 1.2TL. I calculated the amount of material removed from the rear panel. The grooves in the rear panel are 1/4" (0.25") wide and 3/8" (0.375") deep.

The rear panel has a volume of 922.5 cu. in. (20" x 61.5" x 0.75")

There are two vertical grooves measuring 60.5" long. There are five horizontal grooves measuring 17" long.

The volume of the grooves is:

[2 x 60.5 x 0.25 x 0.375] + [5 x 17 x 0.25 x 0.375] = 19.3 cu. in.

19.30/922.5 = 0.0209 = 2.1%

Therefore, only 2.1% of the rear panel MDF material was routed out. Is this enough to have an audible effect on panel rigidity? I would not expect that Polk's engineers would work toward a goal of reducing cabinet resonance and then use a manufacturing procedure that compromised that goal. The internal bracing may counterbalance the reduction in panel rigidity due to the grooves. Is this reasonable?

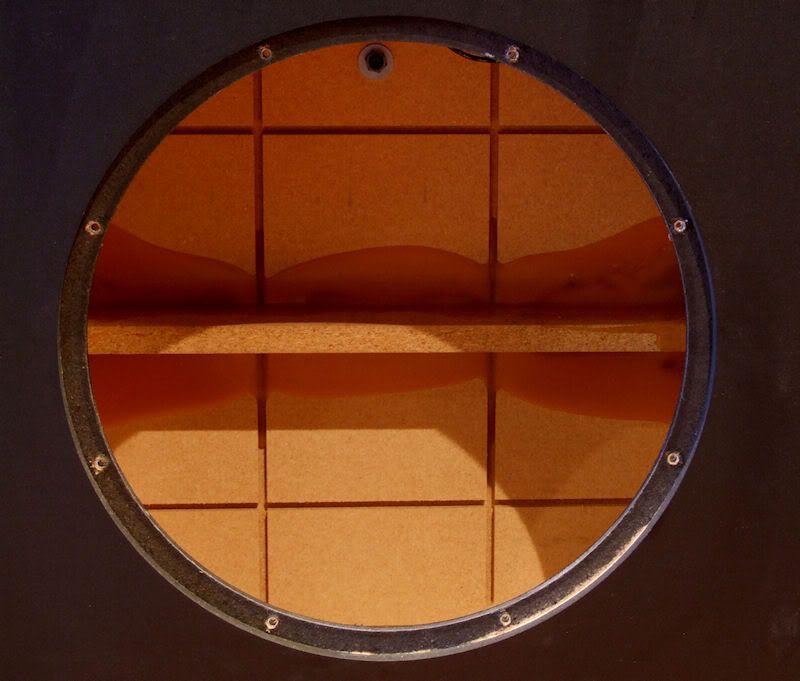

Figure 5. SDA SRS 1.2TL standing wave cancellation grooves.Mr. Bubbles wrote: »cabinet (panel) resonance does indeed appear to be less in the TL's vs the SRS's.

Well, I'm sure you know what Albert Einstein said about "condemnation without investigation...".Mr. Bubbles wrote: »However cabinet flex would be another issue.

What issues have you observed or measured with regard to cabinet flex in the 1.2TL?Mr. Bubbles wrote: »The materials of these 2 cabinets are indeed different and the TL uses the better denser material. however it is still not up to par with modern MDF. But (at least on my cabinets) the material is more of what i would consider a denser particle board.

That is plausible, considering the age of the cabinets. Do you have any comparative sonic performance data on the MDF that was used on the 1.2TL's and the types of MDF available now?Proud and loyal citizen of the Digital Domain and Solid State Country! -

DK, (and all else reading this)

I currently have little equipment to test with as most of that stayed with the audio business that I left approximately 9 years ago. My judgements here are based on testing that i have done in the past on DIFFERENT cabinets and NOT the Polks as well as my knowledge of physical properties both from education and experience. I will continue to try to avoid my own theories since they have caused issues here in the past.

It is completely reasonable that the internal bracing counters weaknesses in the panels be it from the grooves or inherent weaknesses already present without the grooving. I do not think the engineers would have used a process countering their intent either. The difference between panel resonance and panel flex being the trade off. Due to the driver excursion and internal pressures in this cabinet as well as the dynamics of music and the frequencies necessary for any audible recognition of this phenomenon, I believe the slight decrease in rigidity combined with the significant decrease in panel resonance is acceptable if looked at from a retail/ manufacturing standpoint. I was simply making the point that a thinner spot on any board creates a weaker (less rigid ) point on that board in relation to the rest of that board. Given an equivalent density throughout. This I feel is one of those give and take situations. The grooving is a very simple yet highly effective means of countering panel resonance, yet does create weaker points on the panel due to the thinner areas. This can be easily seen by taking a board on almost any material (1/4 mdf is great for this) and cutting a groove in the board . Then flex the board. compare the flexed board to one of the same material and dimensions with no groove. The un-grooved panel will flex in a more even rounded contour. The grooved board will still round somewhat but flex much more sharply along the groove. Eventually the thin are would break first.

I used the word "appears" when comparing the cabinet flex as I have no test equipment to use to measure the difference. however, What I base that judgement on is the use of my hand on the cabinet panels while playing test tones. At much lower frequency extremes (below roughly 35hz) the panels feel to have more vibration and flex. I tried this at identical volume levels according to the dial on the pre amp, and with a slight level adjustment to bring the output level to an identical SPL at 3 ft away centered with crossover panel. I did not record what this spl was at the time.

I do not have any data relating the sonic characteristics of modern MDF as compared to older panels. I simply pointed that out as related to your discussion of the effective density of the type panels used. I realize it is not extremely important to this discussion from a vintage standpoint but wanted others that may be reading this to be aware that vintage MDF is different from what is available now for the most part.If con is the opposite of pro, is Congress the opposite of Progress?!

Monitor 5Jr, Monitor 5, RTA12, RTA 15TL, SDA 2A, 1c, SRS 2, 1.2TL, CRS, Atrium. -

I noted how cabinet resonance affected the sound of my SDA2B's in the BH5 thread.I have found dampening the sides of the cabinet has done more than the back ever had.

I a stripe pattern instead of solid covering. Especially in the area near the drivers and PR.

Both of my SDA2's cabinets got a little to resonant at certain frequencies. I would say somewhere around a low E that gives the cabinet a buzz. I used Dynamat on the back and sides and never heard it again.

I had Monitor 10's that got buzzy as well but it was much lower in the speakers range. I did more experimentation with this speaker and found just placing an X pattern on the sides and back eliminated the resonance.

SRS-1.2TL-with-Blackhole-5-Damper

Now how much flex the cabinet has I would not know as I did not measure the cabinet and never noticed this resonance at all in 1.2TL's that I have had on loan from a buddy before. My guess is the small routed strips stop standing waves from forming on the back wall and eliminate this affect. -

BH5 is more for internal reflections than the cabinet itself resonating. Especially since the cabinet's side walls are shorter than the back wall, if it was affecting the way a cabinet resonates, application of BH5 to the rear wall would make a more substantial difference do to the larger panel."He who fights with monsters should look to it that he himself does not become a monster. And when you gaze long into an abyss the abyss also gazes into you." Friedrich Nietzsche