CRS+ (1989 Version) PCB, Xover and SDA Inductor Upgrade

DarqueKnight

Posts: 6,765

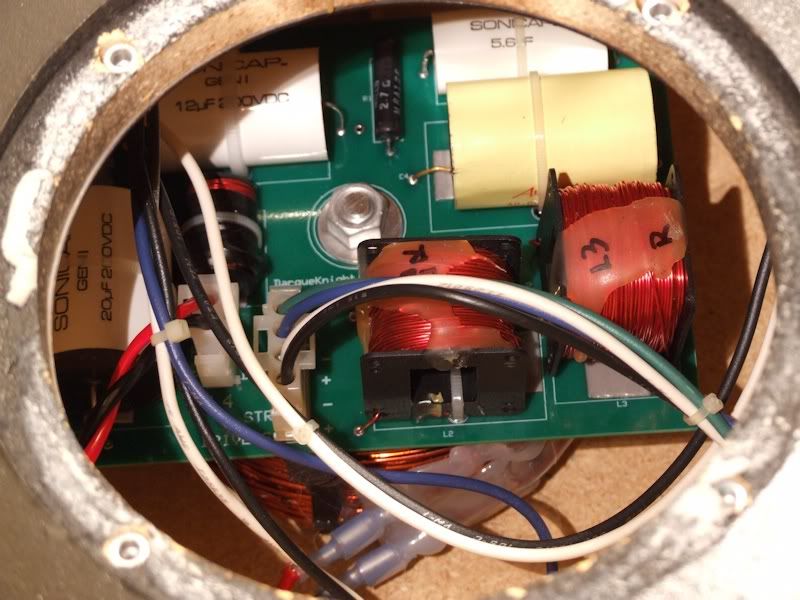

Introduction

The installation of custom printed circuit boards and Northcreek Music Coil SDA inductors worked out very well for my SDA SRS's and SDA SRS 1.2TL's. I decided to continue this process with one pair (of three) of my SDA CRS+'s (1989 version). These CRS+'s had the following previous modifications:

1. Original oak veneer replaced with teak veneer.

2. Stock resistors and capacitors replaced with Mills MRA-12 resistors and AudioCap PPMF polypropylene film capacitors.

3. Polyswitches removed and replaced with wire jumper.

4. Stock binding posts replaced with Cardas CCGR-S binding posts.

5. Stock SDA cable replaced with a custom effective 9 AWG cable made from Monster Z2 Reference speaker cable.

6. Mortite driver, passive radiator and tweeter seals.

7. Steel retaining rings and brackets for drivers, passive radiators and tweeters.

8. Dynamat Xtreme vibration damping material applied to driver and passive radiator baskets.

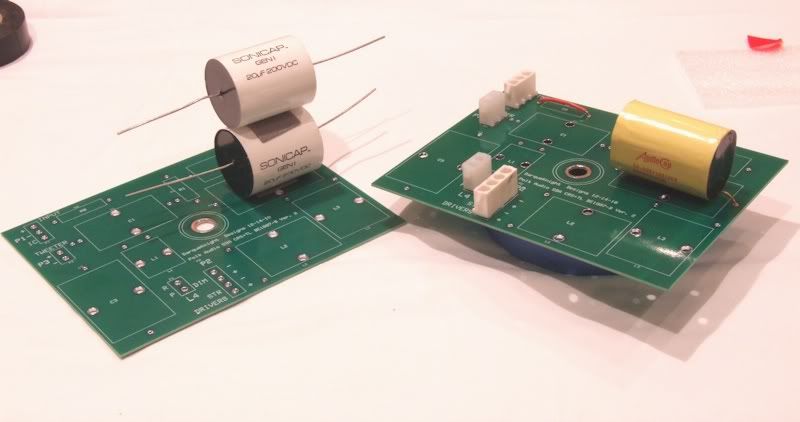

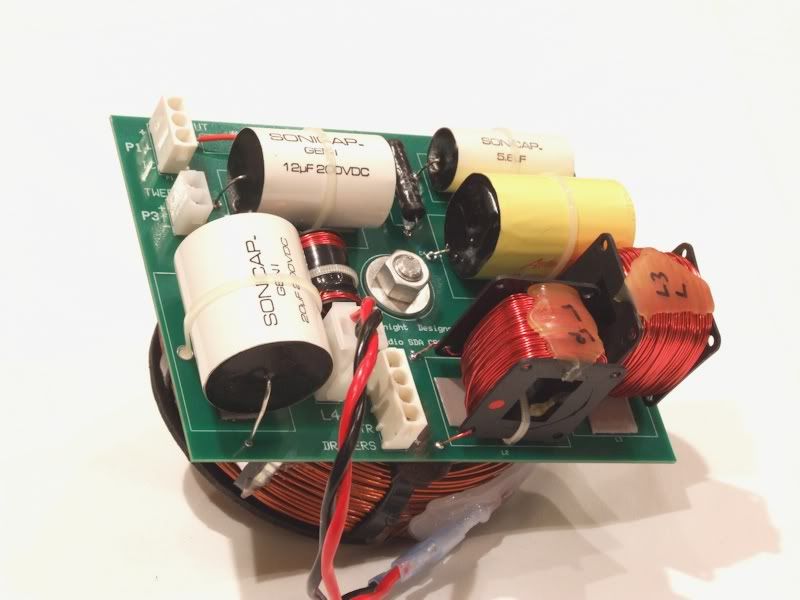

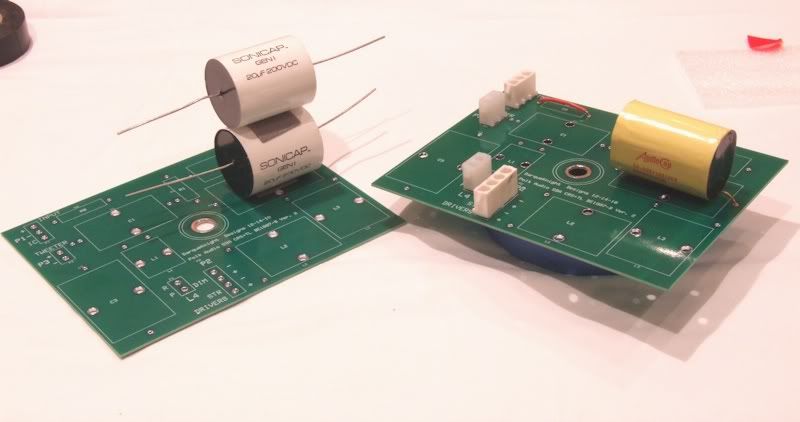

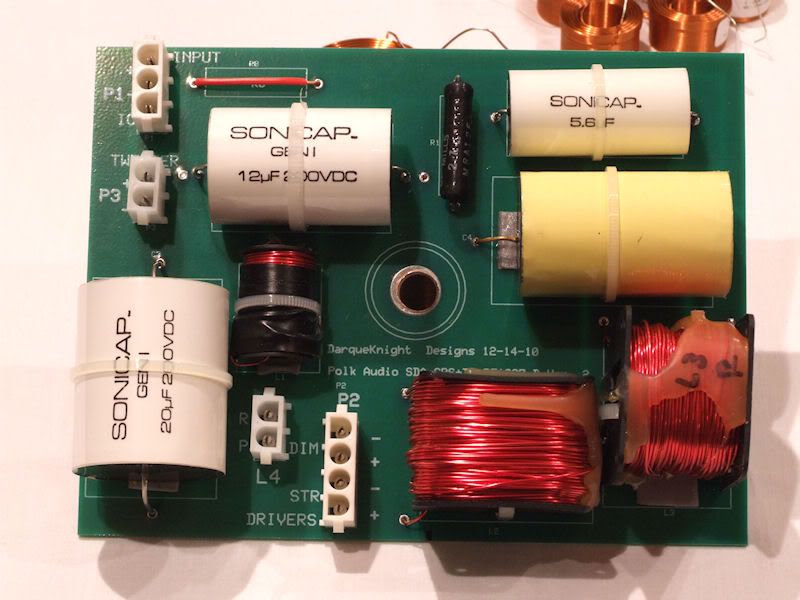

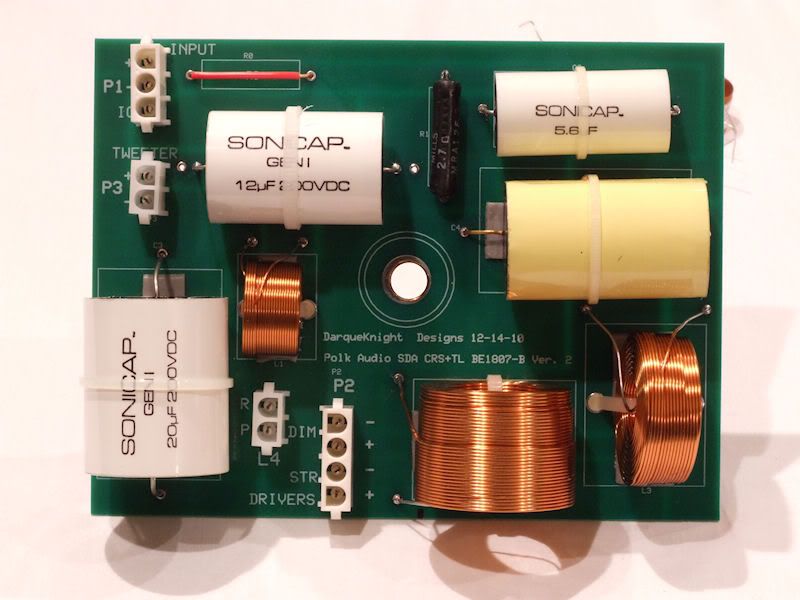

In addition to the circuit board and SDA inductor, all of the AudioCaps, except for the 40 uF shunt capacitor in the dimensional driver circuit, were replaced with Sonicaps. The largest capacitor Soniccraft stocks is 33 uF. Soniccraft informed me that they do not have the capability to make a custom 40 uF capacitor, although they do make custom capacitor values under 33 uF. I could have used a stacked pair of 20 uF capacitors as shown in figures 6 and 7, but one of the objects of doing a custom circuit board was to avoid the need for stacking components. Therefore, my mind would not allow me to use that option. I could have made the circuit board a little longer to accommodate the extra capacitor, but then the board would not be centered over the large inductor and some additional mechanism to prevent board flexing would have been required. Sonicaps in the shunt legs of the driver circuits might be overkill anyway.

I could have made the circuit board a little longer to accommodate the extra capacitor, but then the board would not be centered over the large inductor and some additional mechanism to prevent board flexing would have been required. Sonicaps in the shunt legs of the driver circuits might be overkill anyway.

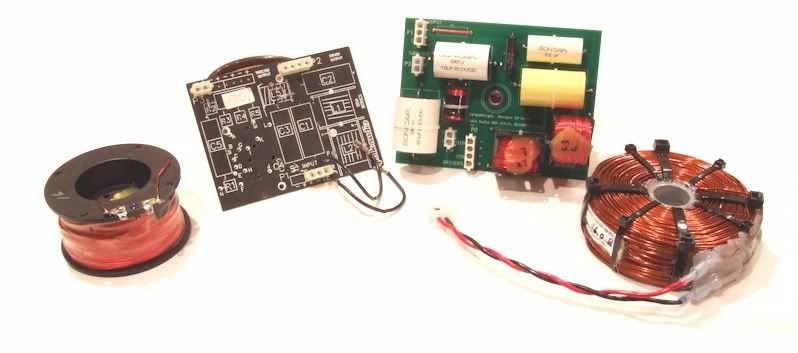

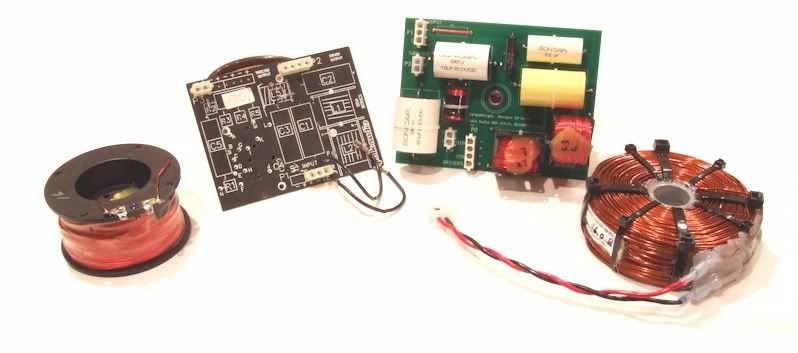

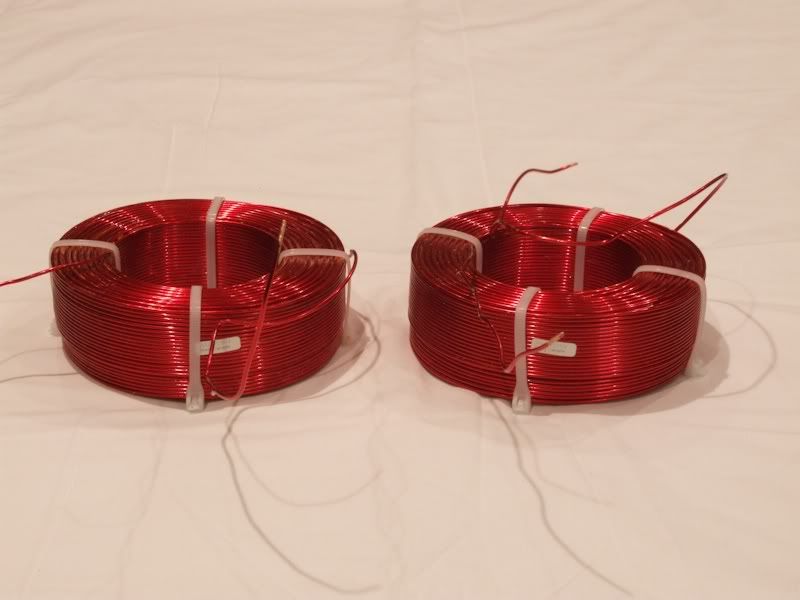

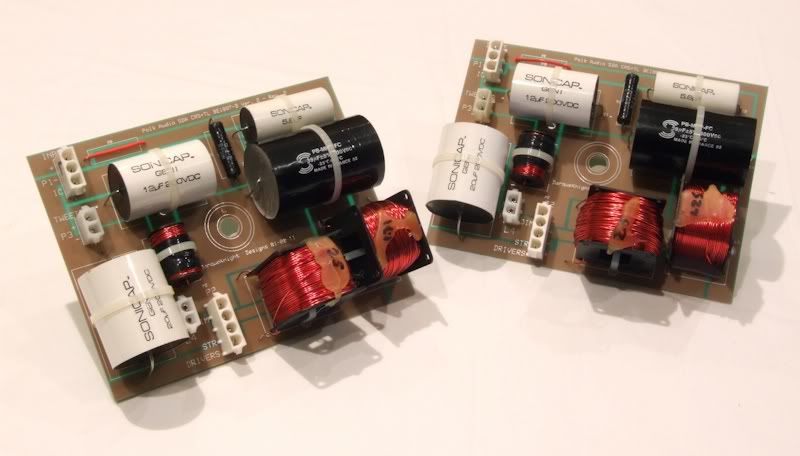

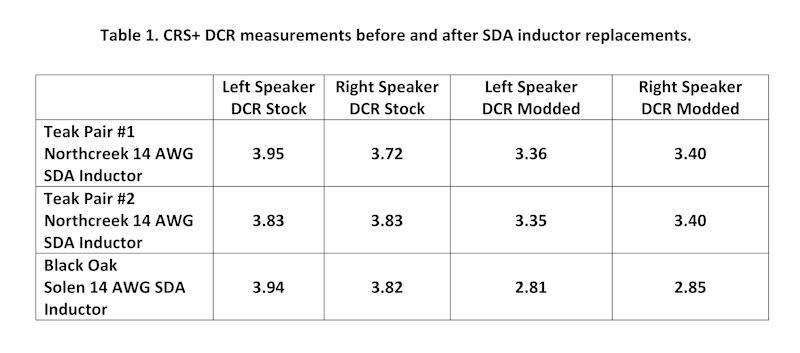

Figure 1. Stock printed circuit board and SDA inductor at left. The new board is 32% larger.

Figure 2. Before: Stock printed circuit board with AudioCaps/Sonicap/Mills and SDA inductor.

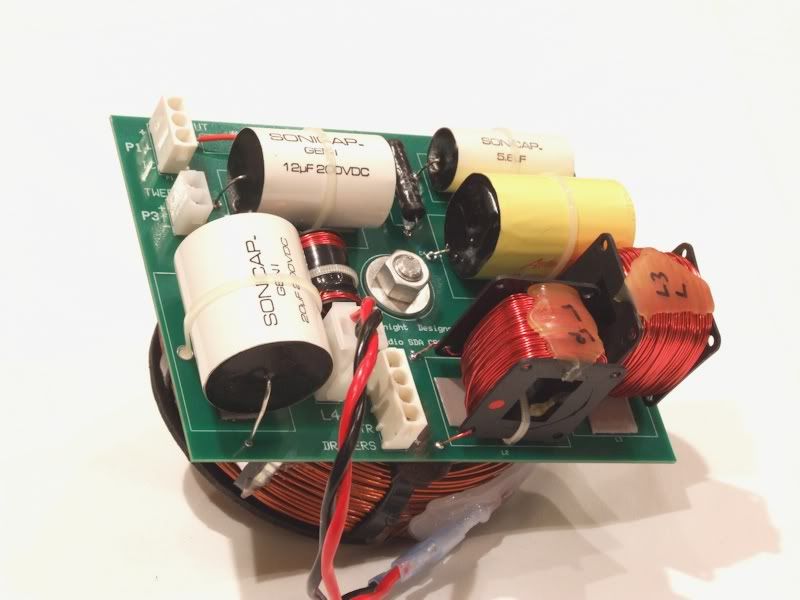

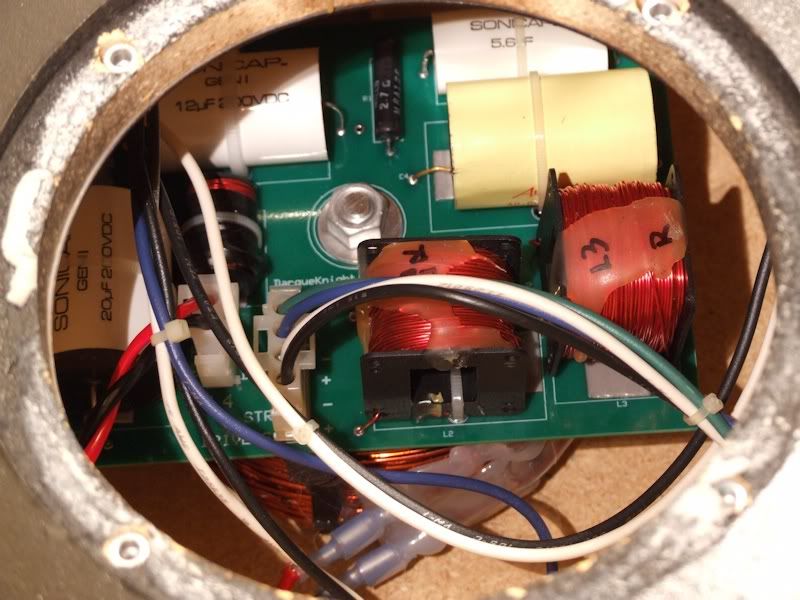

Figure 3. After: Custom printed circuit board and inductor.

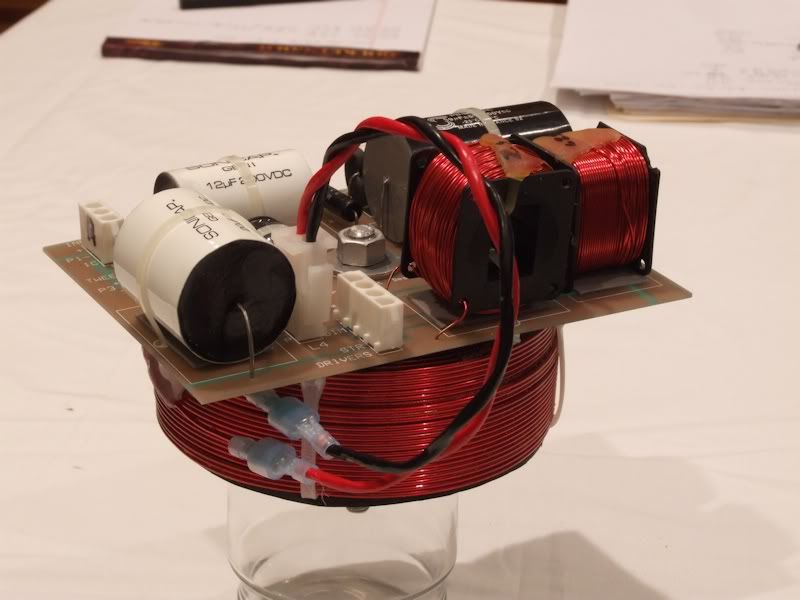

Figure 4. The inductor's cable tie buckles, topped with pads of hot glue, made convenient standoffs for the circuit board.

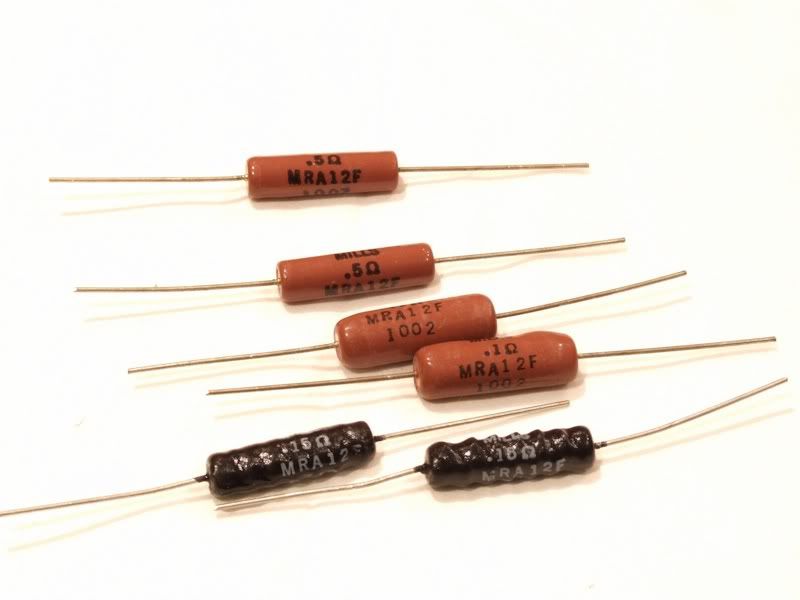

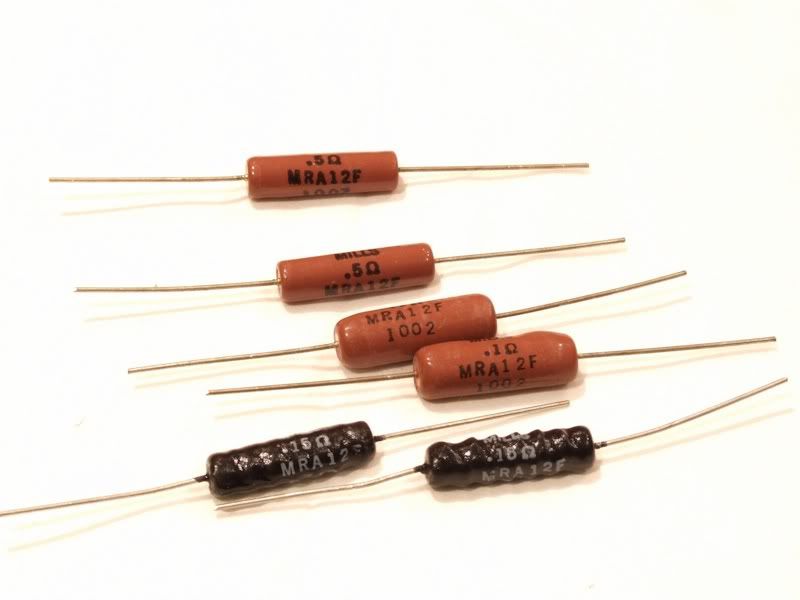

Figure 5. Mills MRA-12 sub-1 ohm resistors (0.1, 0.15, 0.5 ohm). In the future, when I am more dedicated to audio than I am

now, I will evaluate the sound of replacing the polyswitch jumper (the red wire in figure 6) with a small amount of resistance.

Figure 6. Stacked Sonicap 20 uF caps.

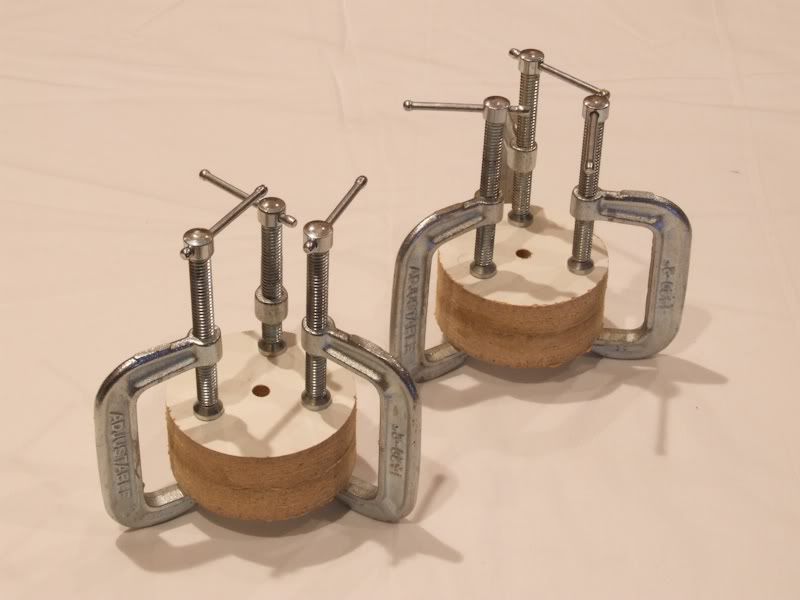

The yellow thing in figure 6 is a 40 uF AudioCap PPMF shunt capacitor for the dimensional driver. Sonicraft does not make a 40 uF capacitor. I would have had to parallel two 20 uF Sonicaps and stack them one on top of the other (figures 6 and 7) or place one 20 uF cap on top of the board and one on the bottom or make the board bigger to accommodate the additional capacitor or mount the cap combination somewhere off the board.

Figure 7. Stacked Sonicap 20 uF caps.

Figure 8. Test fitting for the new board.

Figure 9. It was a challenge fitting a larger board in that tight corner, but it worked out.

Figure 10. The new circuit board and inductor are held in place with a 4" aluminum threaded stud and aluminum nuts and

washers.

Inductor Conditioning and Measurements

The Northcreek inductors were conditioned on an Audiodharma Cable Cooker for 144 hours. Improvements in the inductor's output waveforms were seen up to the 111th hour. When the inductors were reinstalled after 144 hours, evidence of overcooking (blurred transients, loss of overall detail and clarity, diminished sound stage height) were heard. There was also some high frequency grain which I attributed to the new Sonicaps. The sonic weight of images sounded more like listening to FM radio than a CD.

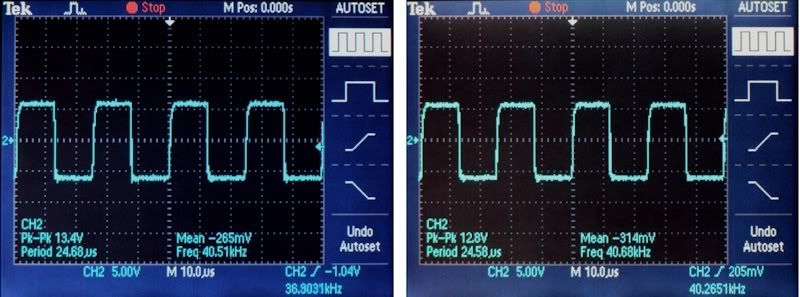

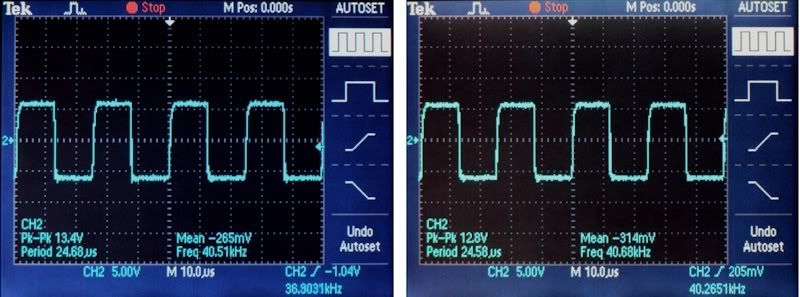

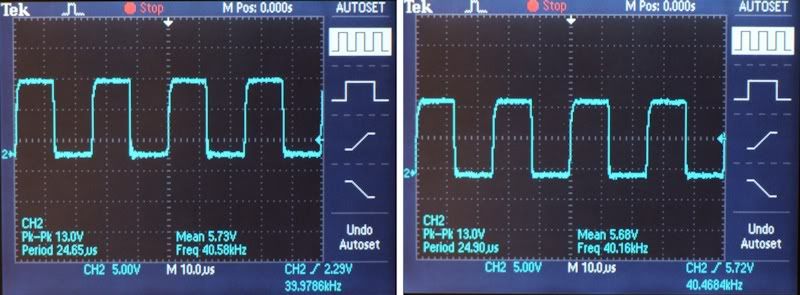

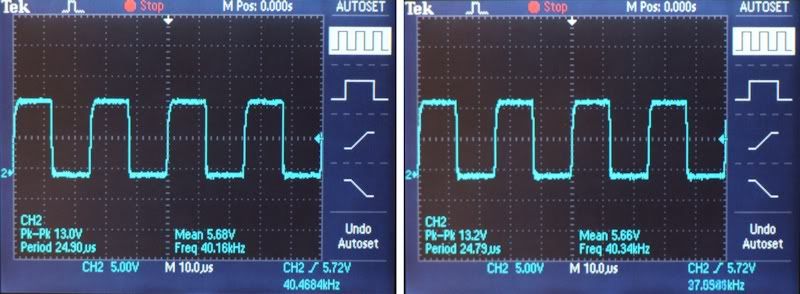

These inductors showed the least pre-cooking output waveform distortion and the best post-cooking waveform improvement of my three Northcreek inductor pairs. Compare the pre-cooking output pulse train in figure 12 (left) below with the pulse train waveforms in figure 8 (right) of the SRS inductors and figure 20 (left) of 1.2TL inductors.

Prior to processing on the Cable Cooker, listening comparisons between the inductor-modified CRS+'s and their non-inductor-modified twins were done for an hour.

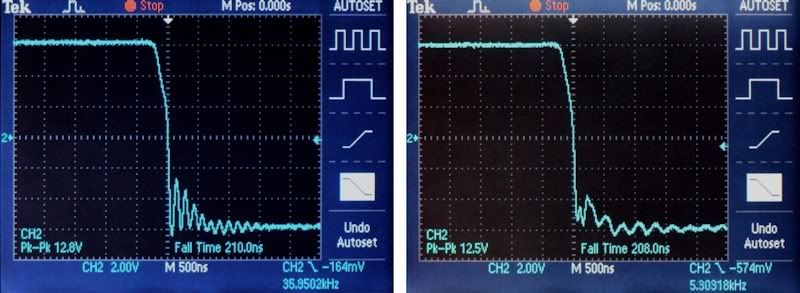

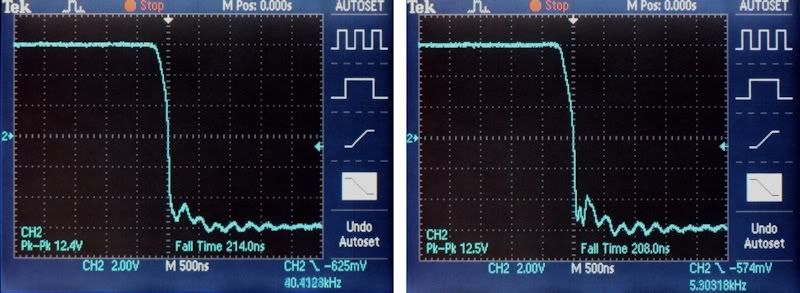

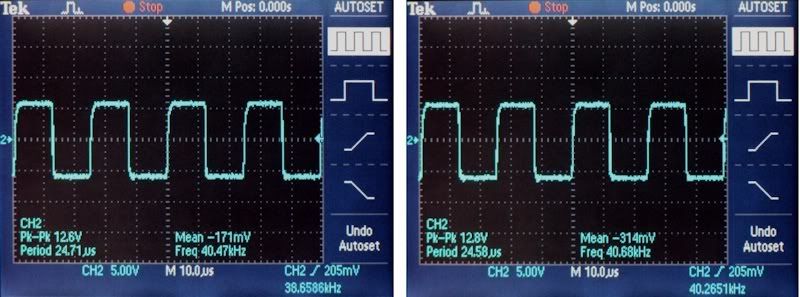

Figure 11. Inductor output pulse train at 0 (left) and 111 hours.

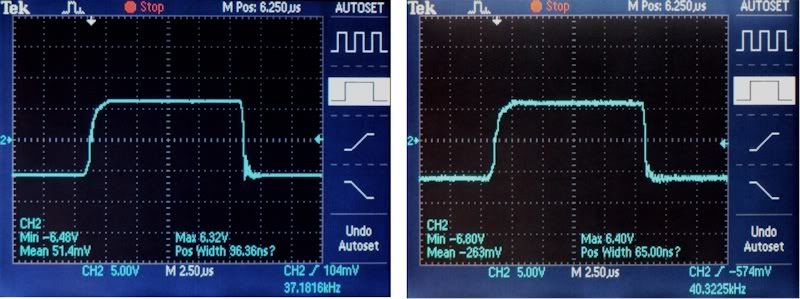

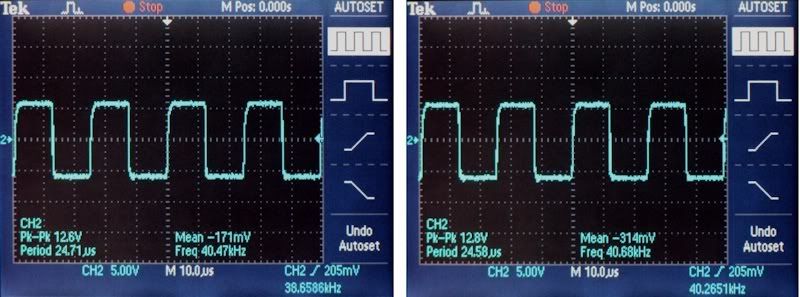

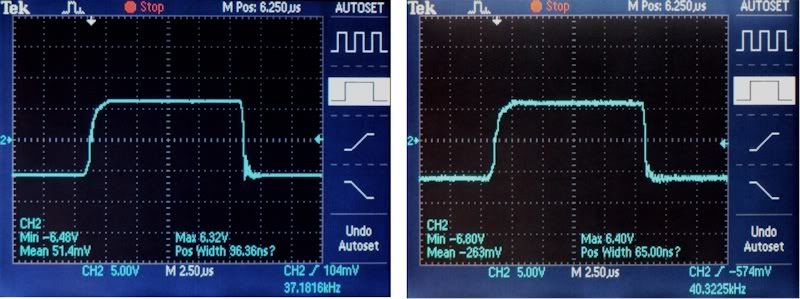

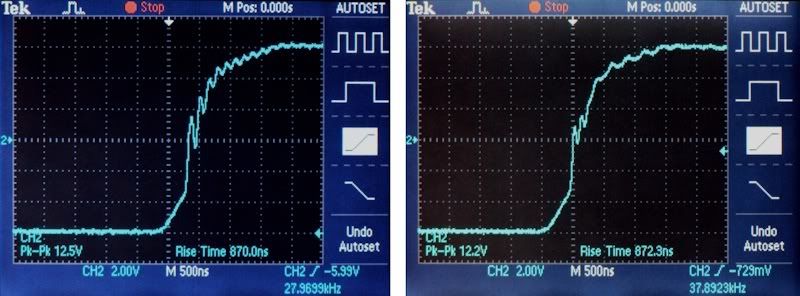

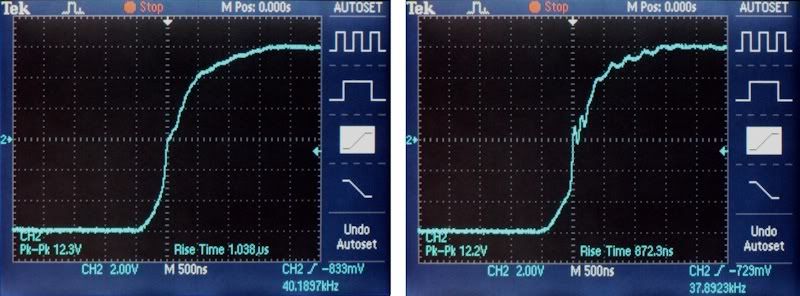

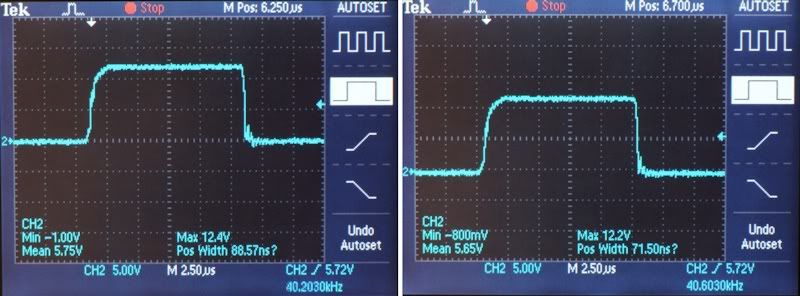

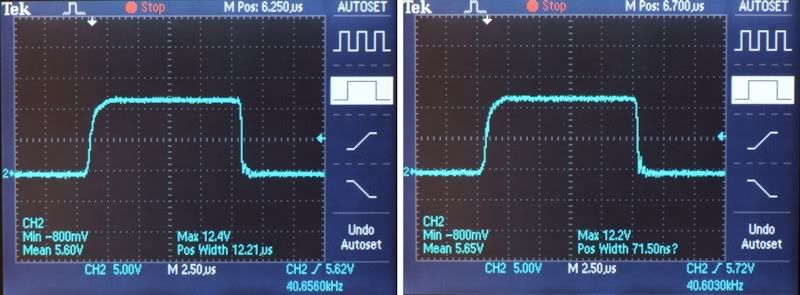

Figure 12. Inductor output single pulse at 0 (left) and 111 hours.

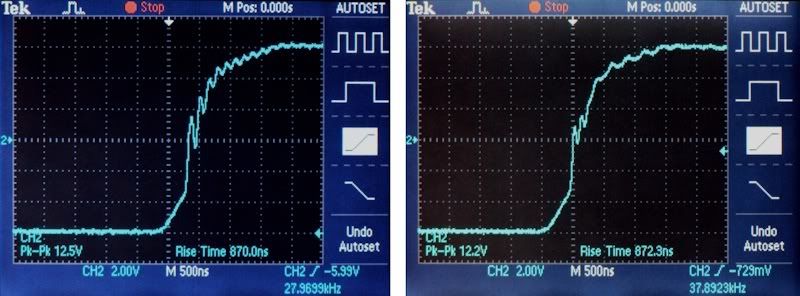

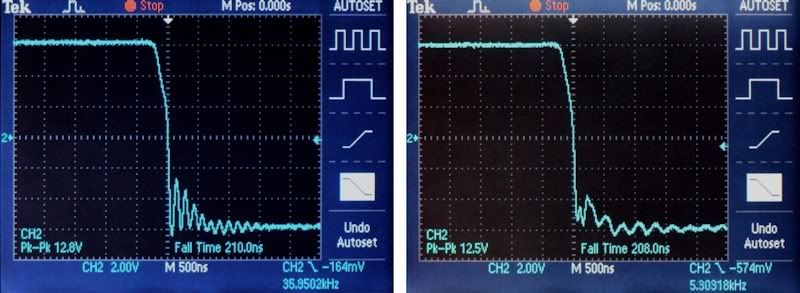

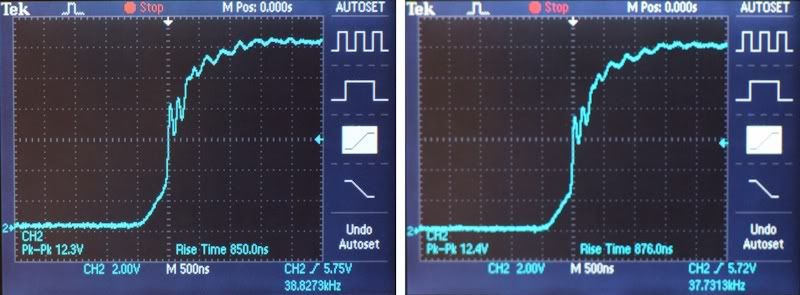

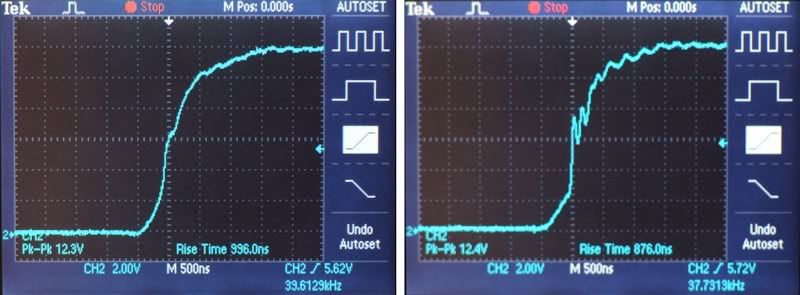

Figure 13. Inductor output pulse rising edge at 0 (left) and 111 hours.

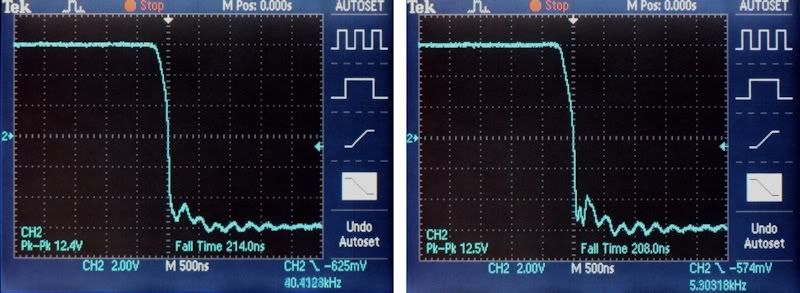

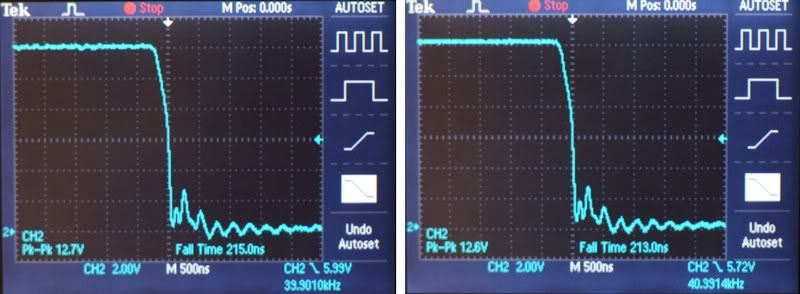

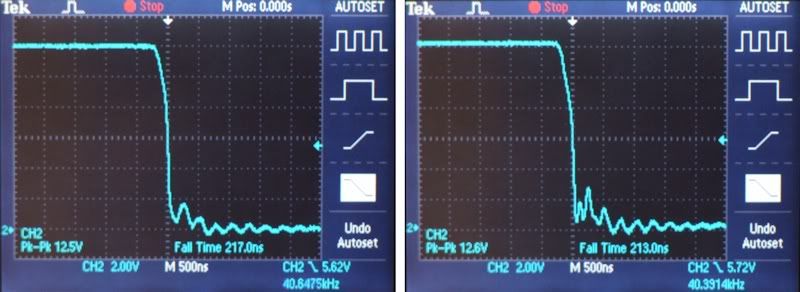

Figure 14. Inductor output pulse falling edge at 0 (left) and 111 hours.

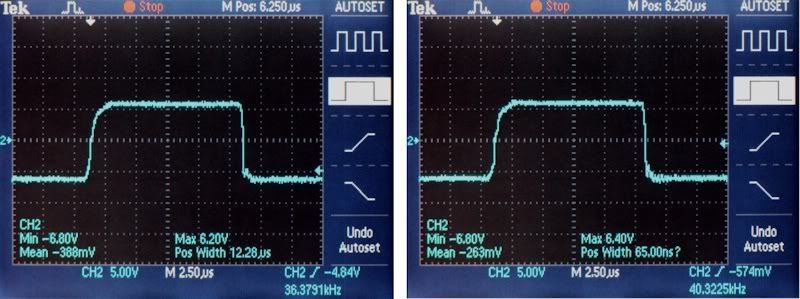

Figure 15. Cable Cooker (left) and inductor output pulse trains at 111 hours.

Figure 16. Cable Cooker (left) and inductor output single pulse at 111 hours.

Figure 17. Cable Cooker (left) and inductor output pulse rising edge at 111 hours.

Figure 18. Cable Cooker (left) and inductor output pulse falling edge at 111 hours.

The output waveform distortion of the CRS+, SRS, and SRS 1.2TL inductors was significantly reduced by processing on the Cable Cooker, but there were some curious variations in the results. The 1.2TL and SRS inductors showed similar pre-cooking output waveform distortion, but the 1.2TL inductors, which had 100 hours of prior use playing music, showed signs of overcooking after 58 hours and took 51 hours of recovery. The SRS inductors, which had 10 hours of prior use playing music, stopped displaying measured and audible improvement after 150 hours, but no evidence of overcooking was heard even after further cooking up to 243 hours. The CRS+ inductors started out with the least amount of output waveform distortion and showed the most improved post-cooking output waveforms. No audible or output waveform improvements were heard or seen with the CRS+ inductors after the 111th hour of cooking. Evidence of overcooking was heard after the 144th hour. Overcooking aberrations were gone after 12 hours of music play.

The only major variable, that I know of, between the three pairs of inductors may have been the amount of shellac absorbed in the coil windings. For mechanical stability and vibration reduction, shellac is vacuum impregnated between the coils and allowed to cure over a few days. Of course, there will be variations in the tightness of the wire windings and therefore variations in the penetration of the shellac. In addition to variations in mechanical stability, the hardened shellac may have had some effect on the dielectric properties of the wire's enamel insulation and also may have contributed to differences in dielectric energy absorption and release. I assume that the thickness of the enamel insulation was consistent among the three pairs of inductors.

The installation of custom printed circuit boards and Northcreek Music Coil SDA inductors worked out very well for my SDA SRS's and SDA SRS 1.2TL's. I decided to continue this process with one pair (of three) of my SDA CRS+'s (1989 version). These CRS+'s had the following previous modifications:

1. Original oak veneer replaced with teak veneer.

2. Stock resistors and capacitors replaced with Mills MRA-12 resistors and AudioCap PPMF polypropylene film capacitors.

3. Polyswitches removed and replaced with wire jumper.

4. Stock binding posts replaced with Cardas CCGR-S binding posts.

5. Stock SDA cable replaced with a custom effective 9 AWG cable made from Monster Z2 Reference speaker cable.

6. Mortite driver, passive radiator and tweeter seals.

7. Steel retaining rings and brackets for drivers, passive radiators and tweeters.

8. Dynamat Xtreme vibration damping material applied to driver and passive radiator baskets.

In addition to the circuit board and SDA inductor, all of the AudioCaps, except for the 40 uF shunt capacitor in the dimensional driver circuit, were replaced with Sonicaps. The largest capacitor Soniccraft stocks is 33 uF. Soniccraft informed me that they do not have the capability to make a custom 40 uF capacitor, although they do make custom capacitor values under 33 uF. I could have used a stacked pair of 20 uF capacitors as shown in figures 6 and 7, but one of the objects of doing a custom circuit board was to avoid the need for stacking components. Therefore, my mind would not allow me to use that option.

Figure 1. Stock printed circuit board and SDA inductor at left. The new board is 32% larger.

Figure 2. Before: Stock printed circuit board with AudioCaps/Sonicap/Mills and SDA inductor.

Figure 3. After: Custom printed circuit board and inductor.

Figure 4. The inductor's cable tie buckles, topped with pads of hot glue, made convenient standoffs for the circuit board.

Figure 5. Mills MRA-12 sub-1 ohm resistors (0.1, 0.15, 0.5 ohm). In the future, when I am more dedicated to audio than I am

now, I will evaluate the sound of replacing the polyswitch jumper (the red wire in figure 6) with a small amount of resistance.

Figure 6. Stacked Sonicap 20 uF caps.

The yellow thing in figure 6 is a 40 uF AudioCap PPMF shunt capacitor for the dimensional driver. Sonicraft does not make a 40 uF capacitor. I would have had to parallel two 20 uF Sonicaps and stack them one on top of the other (figures 6 and 7) or place one 20 uF cap on top of the board and one on the bottom or make the board bigger to accommodate the additional capacitor or mount the cap combination somewhere off the board.

Figure 7. Stacked Sonicap 20 uF caps.

Figure 8. Test fitting for the new board.

Figure 9. It was a challenge fitting a larger board in that tight corner, but it worked out.

Figure 10. The new circuit board and inductor are held in place with a 4" aluminum threaded stud and aluminum nuts and

washers.

Inductor Conditioning and Measurements

The Northcreek inductors were conditioned on an Audiodharma Cable Cooker for 144 hours. Improvements in the inductor's output waveforms were seen up to the 111th hour. When the inductors were reinstalled after 144 hours, evidence of overcooking (blurred transients, loss of overall detail and clarity, diminished sound stage height) were heard. There was also some high frequency grain which I attributed to the new Sonicaps. The sonic weight of images sounded more like listening to FM radio than a CD.

These inductors showed the least pre-cooking output waveform distortion and the best post-cooking waveform improvement of my three Northcreek inductor pairs. Compare the pre-cooking output pulse train in figure 12 (left) below with the pulse train waveforms in figure 8 (right) of the SRS inductors and figure 20 (left) of 1.2TL inductors.

Prior to processing on the Cable Cooker, listening comparisons between the inductor-modified CRS+'s and their non-inductor-modified twins were done for an hour.

Figure 11. Inductor output pulse train at 0 (left) and 111 hours.

Figure 12. Inductor output single pulse at 0 (left) and 111 hours.

Figure 13. Inductor output pulse rising edge at 0 (left) and 111 hours.

Figure 14. Inductor output pulse falling edge at 0 (left) and 111 hours.

Figure 15. Cable Cooker (left) and inductor output pulse trains at 111 hours.

Figure 16. Cable Cooker (left) and inductor output single pulse at 111 hours.

Figure 17. Cable Cooker (left) and inductor output pulse rising edge at 111 hours.

Figure 18. Cable Cooker (left) and inductor output pulse falling edge at 111 hours.

The output waveform distortion of the CRS+, SRS, and SRS 1.2TL inductors was significantly reduced by processing on the Cable Cooker, but there were some curious variations in the results. The 1.2TL and SRS inductors showed similar pre-cooking output waveform distortion, but the 1.2TL inductors, which had 100 hours of prior use playing music, showed signs of overcooking after 58 hours and took 51 hours of recovery. The SRS inductors, which had 10 hours of prior use playing music, stopped displaying measured and audible improvement after 150 hours, but no evidence of overcooking was heard even after further cooking up to 243 hours. The CRS+ inductors started out with the least amount of output waveform distortion and showed the most improved post-cooking output waveforms. No audible or output waveform improvements were heard or seen with the CRS+ inductors after the 111th hour of cooking. Evidence of overcooking was heard after the 144th hour. Overcooking aberrations were gone after 12 hours of music play.

The only major variable, that I know of, between the three pairs of inductors may have been the amount of shellac absorbed in the coil windings. For mechanical stability and vibration reduction, shellac is vacuum impregnated between the coils and allowed to cure over a few days. Of course, there will be variations in the tightness of the wire windings and therefore variations in the penetration of the shellac. In addition to variations in mechanical stability, the hardened shellac may have had some effect on the dielectric properties of the wire's enamel insulation and also may have contributed to differences in dielectric energy absorption and release. I assume that the thickness of the enamel insulation was consistent among the three pairs of inductors.

Proud and loyal citizen of the Digital Domain and Solid State Country!

Post edited by DarqueKnight on

Comments

-

Listening Evaluations

Figure 19. Setting up for listening evaluations.

The newly upgraded CRS+'s are one of two identical pairs. This afforded me the uncommon opportunity to hear the effects of the upgrades against an unmodified identical reference. Both pairs were indistinguishable in listening evaluations done prior to pair #1's inductor/PCB/Sonicap upgrade. Immediately after the upgrade, the modified pair had thin lightweight bass, a contraction of sound stage depth, a loss of bass micro details (growling effects) and a loss of detail at the sides of the sound stage. The modified pair did have a much improved midrange clarity in the center of the sound stage. Music through unmodified pair #2 sounded veiled and slower in pace. Lateral placement of images was the same with both pairs.

After 144 hours, evidence of overcooking was present. Pair #1 sounded dull, lifeless and veiled compared to unmodified pair #2. After 12 hours of music play (FM radio), another listening session with CD's was done. The veiling was gone and the image weight, bass articulation, tactile sensation and detail of the modified pair had significantly improved.

After 25 hours the sound stage depth contraction disappeared and overall clarity and detail had improved to the point where I was hearing fine details not previously documented. There was also a greater sense of free flowing liquidity to the midrange.

At 40 hours post-mod, the inductor-modded pair was again compaired to the non-inductor-modded pair. I didn't listen very long. The non-modded pair wasn't rendered unlistenable by comparison to the modded pair, but they weren't as much fun to listen to anymore. The comparative veiling, less nimble and articulate bass and apparently slower pace of music were distracting.

According to Soniccraft, Sonicaps need about 100 hours of burn in to reach their full sonic potential. I found this to be the case during the Sonicap upgrade for my SDA SRS 1.2TL's. The next listening session was at the 111th hour mark.

The inductor/Sonicap modified CRS+'s showed significant improvements in overall clarity, detail, image weight, and all aspects of bass performance compared to the unmodified CRS+'s. The modified CRS+'s also sounded much louder due to the lowered noise floor of the crossover components.

References

Link: Improvements to the SDA SRS.

Link: Further Improvements to the SDA SRS-Custom PCB and SDA Inductor

Link: Custom Printed Circuit Board for SDA SRS 1.2TL

Link: SDA SRS 1.2TL Sonicap Upgrade

Link: Janne's SDA SRS 1.2TL Crossover and SDA Inductor Upgrade

Link: Audiodharma Cable Cooker ReviewProud and loyal citizen of the Digital Domain and Solid State Country! -

Very nice work as always. I am currently running a .22 ohm Mills resister in my poly switch location. I just put it in yesterday so I really have not had time to evaluate it yet but I have been playing Pandora and listening to TV (Football) all day so hopefully I will get some listening time in the next few days. I tried a .5 ohm resister some time ago and was not happy with what seemed like it was to veiled to me in my system and room. I always thought the jumper wire was just a tad to bright in my system and that is why I went as close to the middle of the jumper and the .5 ohm as I could with the .22 ohm.

ScottI like speakers that are bigger than a small refrigerator but smaller than a big refrigerator:D -

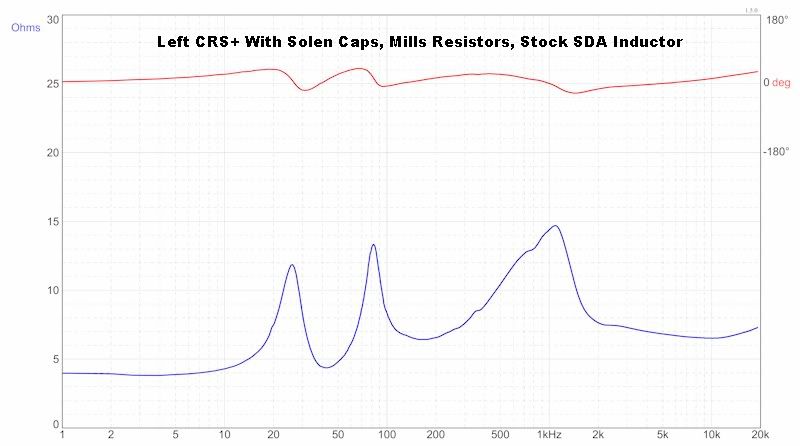

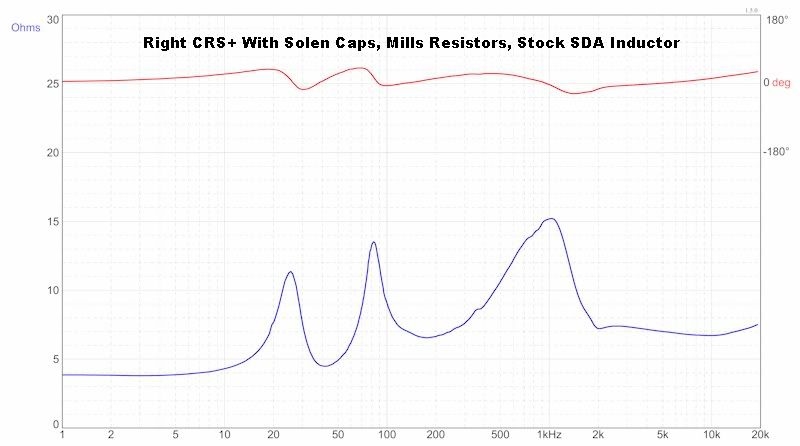

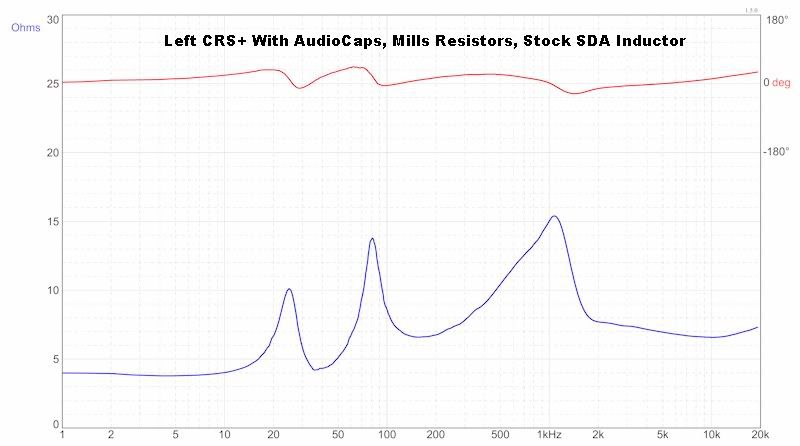

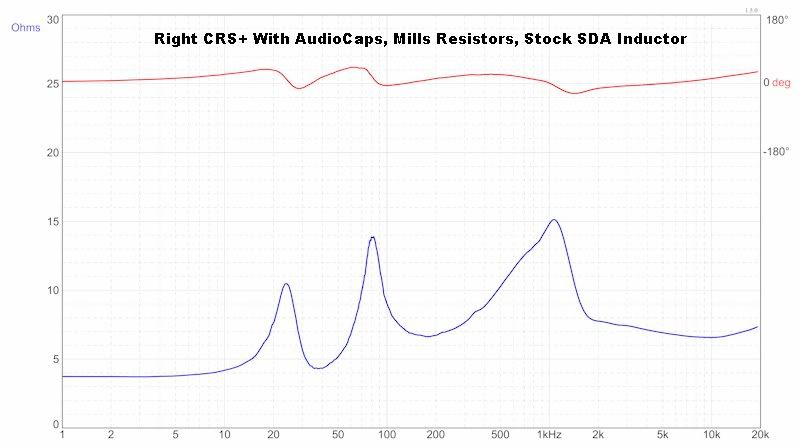

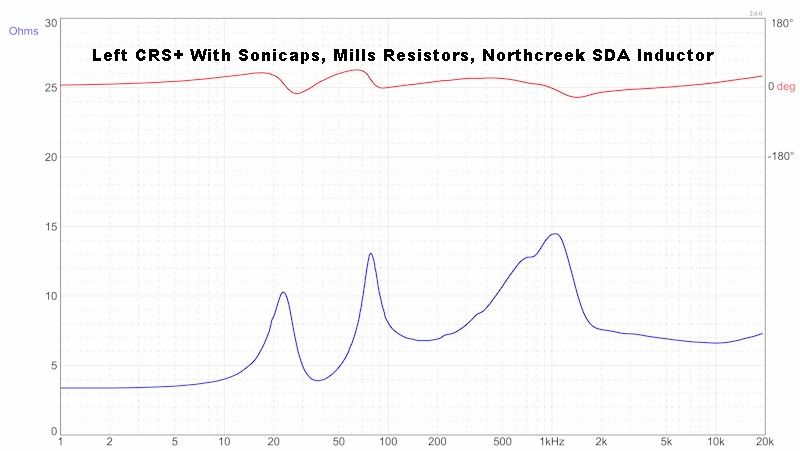

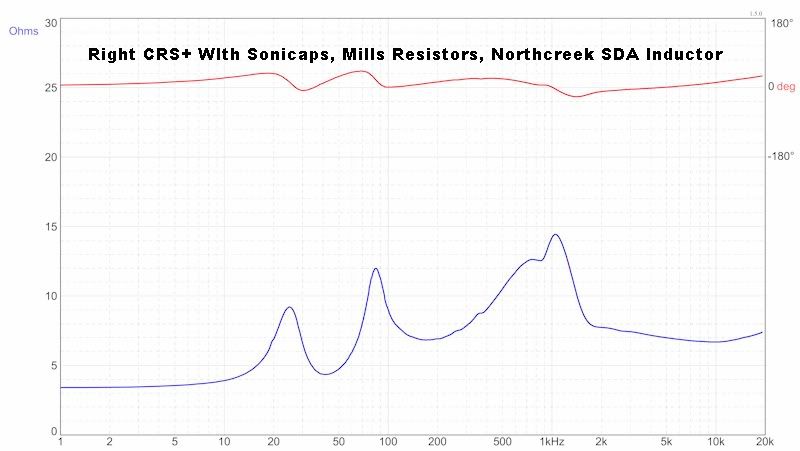

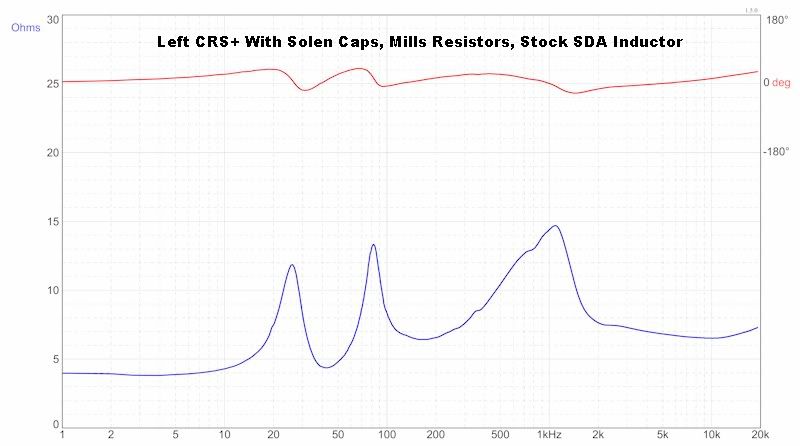

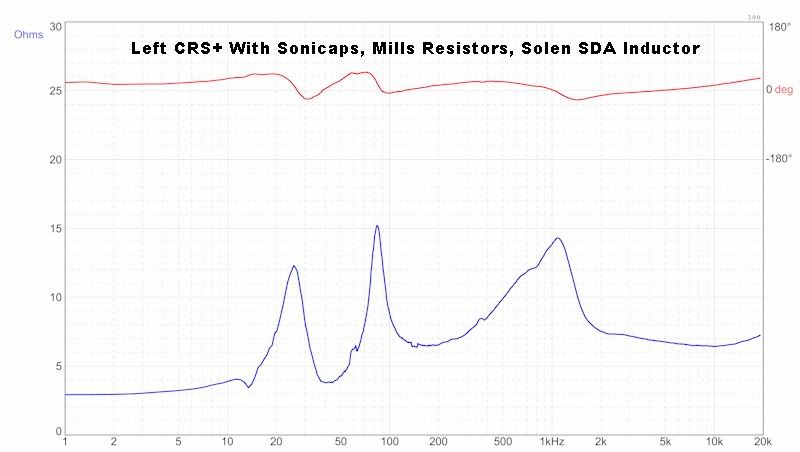

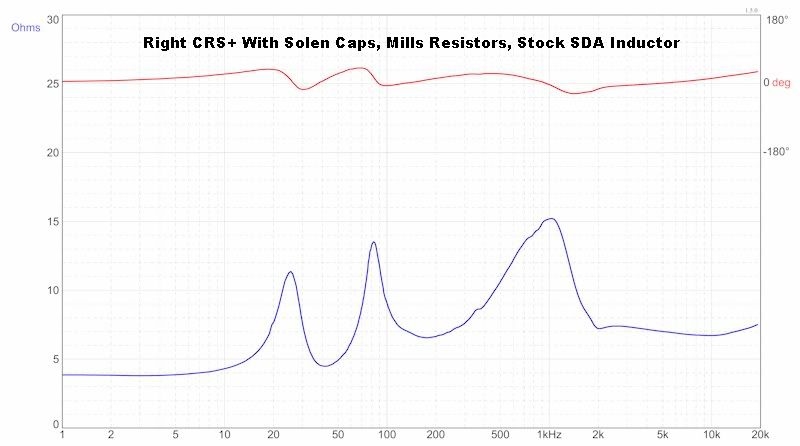

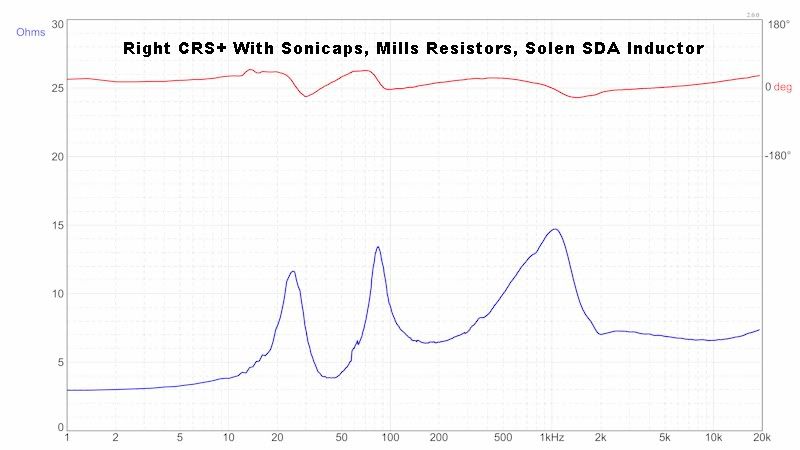

I have three pairs of the 1989 version SDA CRS+, each with differences in crossover components. Below are phase and impedance response plots for each pair. Measurements were taken with the SDA cable connected and speaker cables disconnected. Each pair has the "TL" crossover modification which allows the use of the RD0198 tweeter (SL3000 equivalent).

CRS+ Pair #1

Solen PB series capacitors, Mills MRA-12 resistors, stock inductors.

CRS+ Pair #2

AudioCap PPMF series capacitors, Mills MRA-12 resistors, stock inductors.

CRS+ Pair #3

Sonicap Gen I series capacitors (except for the 40 uF low frequency shunt capacitor, which is an AudioCap PPMF), Mills MRA-12 resistors, stock low pass filter series inductors, Northcreek Audio low DCR SDA circuit inductor. This is the pair that is the subject of this modification report.

Proud and loyal citizen of the Digital Domain and Solid State Country!

Proud and loyal citizen of the Digital Domain and Solid State Country! -

Is that possible?:eek:In the future, when I am more dedicated to audio than I am

nowTesting

Testing

Testing -

Of course it's possible. You'll see in due time.

Proud and loyal citizen of the Digital Domain and Solid State Country!

Proud and loyal citizen of the Digital Domain and Solid State Country! -

DarqueKnight wrote: »Of course it's possible. You'll see in due time.

Hard to imagine, but I can't wait:cool:Pio Elete Pro 520

Panamax 5400-EX

Sunfire TGP 5

Micro Seiki DD-40 - Lyra-Dorian and Denon DL-160

PS Audio GCPH phono pre

Sunfire CG 200 X 5

Sunfire CG Sig 405 X 5

OPPO BDP-83 SE

SDA SRS 1.2TL Sonicaps and Mills

Ctr CS1000p

Sur - FX1000 x 4

SUB - SVS PB2-Plus

Workkout room:

Sony Bravia XBR- 32-Inch 1080p

Onkyo TX-DS898

GFA 555

Yamaha DVD-S1800BL/SACD

Ft - SDA 1C

Not being used:

RTi 38's -4

RT55i's - 2

RT25i's -2, using other 2 in shop

LSI 15's

CSi40

PSW 404 -

....Proud and loyal citizen of the Digital Domain and Solid State Country!

-

....Proud and loyal citizen of the Digital Domain and Solid State Country!

-

I haven't seen this thread untill today. And I never use this 'expression' online. But,

- O M G -

Will you marry me? :rolleyes: -

Very nice! Did you have these up for sale not to long ago? The picture looks like one I saw on S.F craigs list.Again very nice.

-

No, I have not offered these for sale. The picture you saw may have been one of mine. My pictures seem to be very popular with SDA sellers.

Proud and loyal citizen of the Digital Domain and Solid State Country!

Proud and loyal citizen of the Digital Domain and Solid State Country! -

DarqueKnight wrote: »No, I have not offered these for sale. The picture you saw may have been one of mine. My pictures seem to be very popular with SDA sellers.

Are you not going to pursue legal action against these sellers for using your photos off of the internet???

-

I will if their sales revenues are high enough to justify the time and expense of going after them.

Proud and loyal citizen of the Digital Domain and Solid State Country!

Proud and loyal citizen of the Digital Domain and Solid State Country! -

Introduction and Overview

A custom printed wiring board, Sonicap capacitors and a Solen 14 AWG 16 mH SDA inductor were installed in the black oak CRS+ speakers used in my stereo system at work. These speakers had been previously modified as follows:

1. Stock resistors and capacitors replaced with Mills MRA-12 resistors and Solen PB series polypropylene film capacitors.

2. Polyswitches removed and replaced with a wire jumper.

3. Stock binding posts replaced with Vampire binding posts.

4. Stock SDA cable replaced with a custom effective 9 AWG cable made from Monster Z2 Reference speaker cable.

5. Mortite driver, passive radiator and tweeter seals.

6. Steel retaining rings and brackets for drivers, passive radiators and tweeters.

7. Dynamat Xtreme vibration damping material applied to driver and passive radiator baskets.

The Solen 39 uF low lass filter shunt capacitor (40 uF on the schematic) was retained because Soniccraft does not make this value.

Figure 20. The sound of these 22 year old CRS+s has steadily gotten better with age...and modifications.

I originally ordered a pair of the same Northcreek Audio 14 AWG 16 mH inductors the went into my other two pairs of CRS+s and my SRSs. However, I received an order confirmation email asking if I was aware of the huge price increase (43%) that had gone into effect since my last order. This was due to a 50% price increase from Northcreek's copper supplier. Rather than a price along the lines of the $243.47 and $241.95 I had paid for my two most recent orders, this inductor pair was going to cost $364.95! I cancelled the Northcreek order and placed an order for two Solen 16 mH 14 AWG inductors with a total price of $155.36. It turned out that the Solen inductors were a better choice in this application.

Figure 21. The Solen inductors provided better sound performance than the Northcreek inductors at less than half the cost.

The Solen inductors are about the same size and weight as the Northcreek inductors (compare to figure 3 in post #1).

Figure 22. Mounting spools (3" dia.) for the Solen inductors were made from two 3" diameter 3/4" thick MDF discs glued together.

Figure 23. Populated custom printed circuit boards.

For the first pair of teak CRS+s, I used a board fabricator (ExpressPCB) whose communication, customer service, turnaround time (four days) and quality were exemplary...but they are expensive.

For the printed circuit boards for the teak #2 and black oak CRS+s, I used a board fabricator in Asia (Futurlec) whose price was 1/2 that of ExpressPCB, but whose turnaround time was much longer (five weeks) and whose customer service was sometimes difficult. Whereas ExpressPCB would respond to emails within a matter of hours, Futurlec sometimes took two to three days. There was a misunderstanding (on the factory's part) regarding my order and it took a week of back and forth emails to get it resolved. Futurlec emails always came from the same customer service employee, but it sometimes seemed like it was a different person on the other end because I had to keep repeating information that I had given in previous emails. Maybe it was the same person and they were just overwhelmed with other orders. Futurlec makes a good quality product, although some of the standard features of ExpressPCB boards are extra cost options with Futurlec (e.g. plated through holes, top side solder mask, heavier than one ounce copper plating).

The only difference between teak pair #1 and teak pair #2 was pair #1 had the ExpressPCB boards and pair #2 had the Futurlec boards. Both sets of speakers sounded identical.

Figure 24. Completed board/SDA inductor assembly for black oak CRS+s.

Measurements

Similar to the 10 AWG Solen inductors installed in my SDA SRS 1.2TLs, the Solen 14 AWG inductors displayed better noise performance and better bass performance right out of the box compared to the Northcreek inductors. Solen recommends a burn in time of 100 hours for their inductors. I did 111 hours on the Cable Cooker with the Northcreek inductors, but only did 63 hours on the Cooker with the Solen inductors because I did not see any improvements in the output waveforms after the 48th hour. In retrospect, I should have left them on the cooker for at least 100 hours because there may have been some additional conditioning benefits that did not show up on the oscilloscope. There was an additional 102 hours of burn in with music due to the Sonicaps.

The interested reader can compare the waveforms below to the Northcreek 14 AWG inductors (figures 11-18 here) and the Solen 10 AWG inductors (figures 1-9 here).

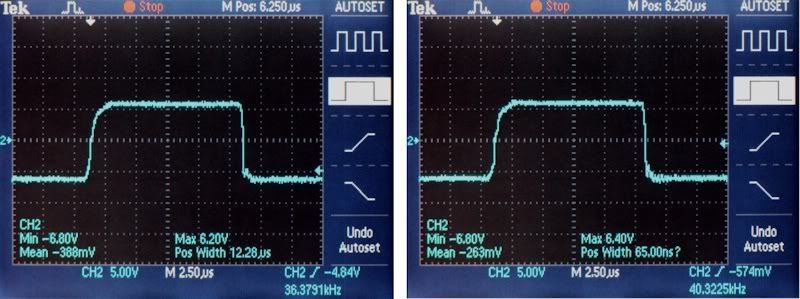

Comparisons of Solen Inductor Output waveforms at 0 and 63 Hours of Cable Cooker Processing (Figures 25-28)

Figure 25. Solen inductor pulse train output at 0 hours (left) and 63 hours.

Figure 26. Solen inductor single output pulse closeup at 0 hours (left) and 63 hours.

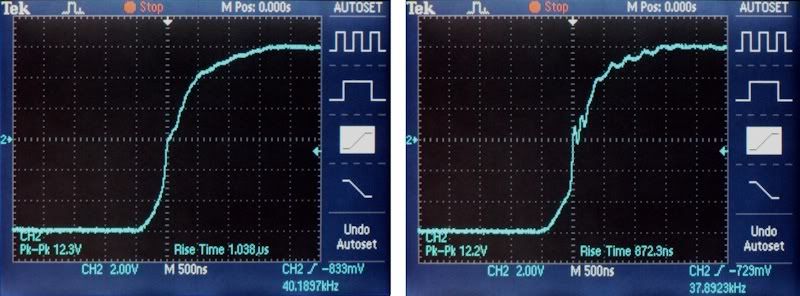

Figure 27. Solen inductor output pulse rising edge at 0 hours (left) and 63 hours.

Figure 28. Solen inductor output pulse falling edge at 0 hours (left) and 63 hours.

Comparisons of Solen Inductor Input (from Cable Cooker) and Output Waveforms after 63 Hours of Processing (Figures 29-32)

Figure 29. Cable Cooker output signal (left) and Solen inductor output signal.

Figure 30. Cable Cooker output signal pulse closeup (left) and Solen inductor output signal pulse closeup.

Figure 31. Cable Cooker output signal pulse rising edge (left) and Solen inductor output signal pulse rising edge.

Figure 32. Cable Cooker output signal pulse falling edge (left) and Solen inductor output signal pulse falling edge.

Pre-mod and Post-mod (Solen inductors and Sonicaps) Impedance Plots

Figure 33. Left speaker pre-mod impedance response.

Figure 34. Left speaker post-mod impedance response.

Figure 35. Right speaker pre-mod impedance response.

Figure 36. Right speaker post-mod impedance response.

The Solen 14 gauge 16 mH inductors have a nominal DCR of 1.24 ohms. I measured 1.4 ohms for each inductor using a digital multimeter and 0.946 ohm and 0.945 ohm using the Dayton Audio WT3 software based measuring tool. The Northcreek audio 14 gauge 16 mH inductors have a nominal DCR of 1.22 ohms. I measured 1.3 ohms for each inductor using a digital multimeter and 0.955 ohm and 0.940 ohm using the Dayton Audio WT3 software based measuring tool.

According to Solen, their standard inductors are manufactured using a high precision honeycomb structured "perfect lay" hexagonal winding technique. The alternating current passing through an inductor will induce an alternating magnetic field, which will produce a mechanical vibration in each turn of wire corresponding the applied audio frequency. This mechanical vibration generates an acoustic radiation that will cause a non-linear loss and distortion which causes audio frequency noise. The high precision perfect lay hexagonal winding technique eliminates most electro-mechanical vibration losses. Each inductor is dipped in an industrial varnish that impregnates and totally solidifies all the outside turns.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Listening Evaluation

Listening evaluations were done at work and at home in my home theater system with the following equipment:

Office System

Nakamichi CA-5AII Preamp

Adcom GFA-555 Mk II Power Amp (325 watts per channel into 4 ohms)

Yamaha TX-1000U Digital Tuner

Yamaha CDX-1110U CD Player

Signal Cable Analog Two Interconnects

Signal Cable MagicPower Power Cords

Monster Z2 Reference Speaker Cable

Home Theater System

Sony TA-P9000ES Preamp

Pioneer Elite BDP-09FD Blu-ray/CD/DVD Player

Adcom GFA-5500 Power Amplifier

Monster Cable Z100i Interconnects

Monster Z2 Reference Speaker Cable

PS Audio Statement SC Power Cords for Components

PS Audio Power Plant Premier AC Regenerator

PS Audio AC-5 Power Cords for Power Plant Premier

PS Audio Soloist SE In-wall Power Conditioner

Metal Technology MT-30 Speaker Stands (One Pair of Stands Per Speaker)

The first listening evaluation was done at the office. The CRS+s are placed in two bookcases at the ends of the wall facing my desk. The inner sides of the speakers are 5 feet apart and I sit on axis 7 feet from the speaker front plane.

After replacing the black oak CRS+s (stock SDA inductor) with the teak #2 CRS+s (Northcreek SDA inductor), the improvement in bass, image weight and overall clarity was immediately apparent, even at the low sound levels used at work. The teak #1 CRS+s were left at the office while the black oaks were taken home for modification. The black oak/teak comparison was done out of curiosity. I really was not interested in doing another speaker mod project, but after I experienced Such Good Sound from the Sonicap and inductor modified teak CRS+s, I could not go back.

The black oaks were modified in two stages. The first stage consisted of installing the burned in Solen inductor and new circuit board with all Solen capacitors, then a listening test at home comparing the black oaks to the teak #2s. The second stage consisted of replacing the Solen capacitors (except for the 39 uF) with Sonicaps, then burning in with music for 102 hours, then a listening test at home comparing the black oaks to the teak #2s. After the home listening evaluations, the black oaks were returned to the office.

Figure 37. Setting up for listening trials.

The black oak inductor change resulted in heavier images than the teak with image placement the same. The black oak bass weight and articulation was much better but the overall clarity was not as good as the teak pair. Listening was done with both black oaks in place, then a black oak on the left and a teak on the right, then both teaks. In the half-and-half configuration, the teak side sounded louder and clearer.

Figure 38. Half-and-half listening evaluation.

The Sonicaps were installed in the black oaks and compared to the teak #2s. There was a small improvement in clarity, but the teaks still sounded better. After 102 hours of music play burn in, the black oaks finally "stood up". They had more overall clarity, more image weight, clearer vocals, more bass slam, more bass articulation, more bass weight and sounded (and measured) louder than the teak #2s.

The black oaks were next taken to the office and compared to the teak #1s. The same improvements heard at home were heard at the office. Additionally, I could turn the music down to below my usual listening level and still have excellent detail and tactile sensation.Proud and loyal citizen of the Digital Domain and Solid State Country! -

I wanted to replace the original HF and LF inductors in my three pairs of CRS+'s with perfect lay inductors, but Solen could not accommodate me. Jantzen makes the required 0.4 mH 22 AWG, 1.25 mH 20 AWG and 2.5 mH 20 AWG perfect lay inductors.

Figure 39. Such good coils.

Figure 40. Custom CRS+ crossover board with original inductors.

Figure 41. Custom CRS+ crossover board with Jantzen inductors.

Figure 42. After 23 years of faithful service, the Class of '89 goes into retirement.

Typical values for the stock inductors in my CRS+'s were as follows:

0.40 mH, 22 AWG

> 0.416 mH, 0.71 ohms.

1.25 mH, 20 AWG

> 1.279 mH, 0.88 ohms.

2.50 mH, 20 AWG

> 2.470 mH, 1.27 ohms.

16 mH, 18 AWG

>16.300 mH, 2.66 ohms.

The replacement Jantzen inductors (special ordered from Parts Express) had the following measurements:

0.40 mH, 22 AWG

> 0.413 mH, 0.64 ohms.

1.25 mH, 20 AWG

> 1.259 mH, 0.82 ohms.

2.50 mH, 20 AWG

> 2.509 mH, 1.34 ohms.

Jantzen part numbers and prices were:

0.40 mH, 22 AWG, Part No. 1489, $2.86.

1.25 mH, 20 AWG, Part No. 1137, $5.63.

2.50 mH, 20 AWG, Part No. 1695, $8.61.

The Jantzen inductors took six weeks to arrive from Denmark. The standard special order delivery period for Jantzen parts is eight weeks.

The 16 mH Solen inductors took eight days to arrive from Canada.

Summary of Sound Improvements

1. Improved overall clarity and detail, particularly in dense, complex orchestral and choral pieces.

2. More low level detail as evidenced by hearing more as a song is fading out and by turning the volume way down.

3. More bass articulation and micro-growls.

4. More ambient information (echoes and reflections).

5. Increased rhythm, pace and liquidity of rapid music passages.

6. Apparently louder sound due to lowered noise floor.

7. Increased image weight.

8. There were no changes in image localization or sound stage dimensions.

9. There were no changes in tactile sensation.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Very cool & detailed. Great work I'd love to own a pair some day.Monitor 7C's With Tubes

-

Ray,

Do you have the part # for the Solen 16mh inductors? Did you order them from parts connections? -

Yes, I ordered from Parts Connexion. The part number for the Solen 16mH 14 AWG inductors was Solen-75137. I don't see Solen's perfect lay single core inductors on the Parts Connexion website now, so these would be a special order.

The part number on the Solen website is S1412.0. At the time I ordered in March 2011, Parts Connexion's prices were lower than ordering directly from Solen. The price on the Solen website is $82.92 Canadian, which is $63.62 US. I paid $67.68 in 2011.Proud and loyal citizen of the Digital Domain and Solid State Country! -

Thanks Ray, I have had all the other inductors with the northcreek 16mh for about 2 years now.. LOL!!

I will order these and finish the upgrades in my CRS+'s -

I believe the part number is S1416.0

https://solen.ca/products/standard-inductors-14awg-1-63mm/s1416-0/ -

Thanks for catching that.Proud and loyal citizen of the Digital Domain and Solid State Country!