Driver and Passive Radiator Rings For The SDA CRS+

DarqueKnight

Posts: 6,765

Introduction

I thought this mod on one pair of my "baby SDA's" would be as easy as a day at the beach, but it turned out to be more like a long day at work. It was worth it.:) This pair of 1989 version CRS+'s is clad in the elegant black oak veneer with satin finish. The following modifications were previously performed:

1. Crossover upgrade with Mills MRA-12 resistors, Clarity Cap and AudioCap polypropylene capacitors, "4.1TL" modification which allowed the use of the RD-0198 (SL3000 replacement) tweeter.

2. Mortite seals for tweeters, drivers and passive radiators.

3. Custom heavy gauge SDA interconnect cable.

4. Replacement of SL2000 tweeters with RD-0198 tweeters.

5. Vampire binding posts.

6. Foam rubber damping material on the driver and passive radiator baskets.

My experience installing rings in my SDA SRS 1.2TL's is discussed here. My experience installing rings in my SDA SRS's is discussed here.

Based on my previous experiences, I expected this modification to take about two hours. It actually took a little over five hours due to some unforeseen difficulties. This time included a half hour to install Dynamat Extreme vibration damping material on the driver and passive radiator baskets.

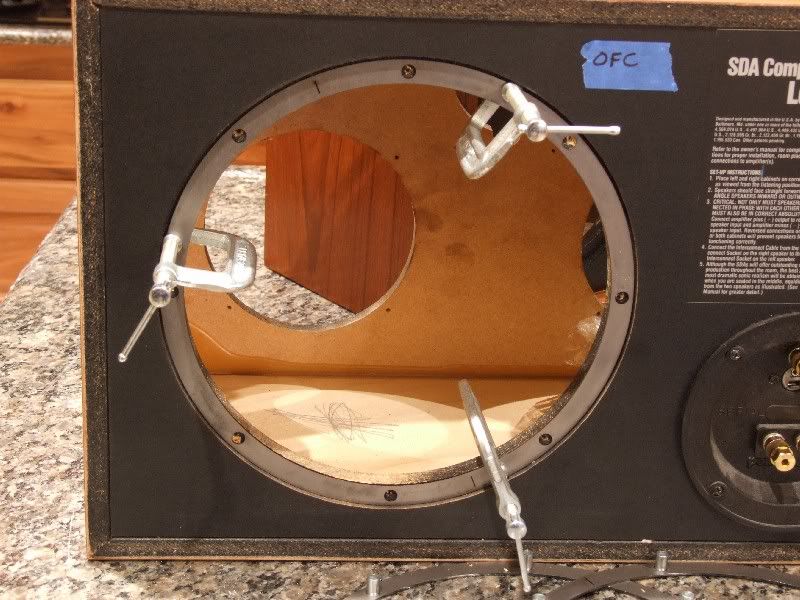

Figure 1. CRS+ cabinets prepped for surgery.

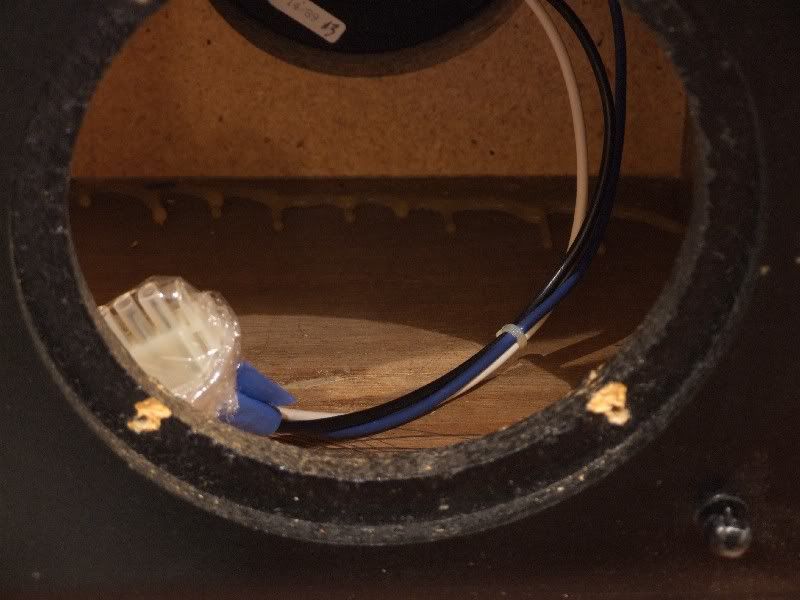

Figure 2. Foam rubber insulation on the metal baskets was replaced with Dynamat Extreme.

Some Surprises

Installation of the driver rings was easy and went as expected. I was surprised by the brittleness of the cabinet material. Figures 3 and 4 show the severe cracking that occurred during the drilling of two of the driver ring holes. Most of the other drilled holes exhibited much less severe, or no, cracking. The grade of MDF used for the CRS+ cabinet material is a lot different from that used in the SRS series SDA's.

Figure 3. Cracked driver hole on right CRS+.

Figure 4. Cracked driver hole on left CRS+.

Two of the driver cutouts were close to cabinet corners that had about 10.8 pounds of glue on them. Some of that glue needed to be cut and pried off to clear space for the rings (figure 5). I used a very sharp box cutter to slice through the glue and a large flat screwdriver to pry it off.

Figure 5. Gobs and gobs of glue in the corners, some of which had to be cut away to provide space for this ring.

Figure 6 shows the amount of glue that had to be removed near one cabinet corner, the toothpicks that were formerly used to "fix" five stripped driver screw holes and some of the cracked off MDF material that resulted from drilling. Considering the brittleness of the cabinet material, it is easy to see why the screw holes were so prone to stripping. Fortunately, the rings make that concern a thing of the past.:)

Figure 6. Top to bottom: glue that needed to be removed, "toothpick fixes" that were used to secure stripped driver screw holes, cracked

off cabinet material due to drilling.

When I started to install the ring for one of the passive radiators, I discovered that the drilling template was too big to fit inside the passive radiator cabinet cutout. I measured the cabinet cutout diameter as 10-10/64", the passive radiator rim diameter as 10-6/64", the ring diameter as 10-15/64" and the drilling template diameter as 10-15/64". The drilling template diameter should have been about the same as the passive radiator rim diameter, but it (and the ring diameter) exceeded it by a little over 1/16th" all around (figure 7). The larger ring diameter was not an issue since the ring holes lined up with the passive radiator rim holes and the ring was going inside the cabinet.

When I taped the over-sized template over the passive radiator cutout, I saw that four of the template holes lined up perfectly with the four screw holes in the cabinet cutout. The template's internal diameter also matched the internal diameter of the cabinet cutout. Therefore, the only thing wrong was the template's external diameter.

Larry (forum member TOOLFORLIFEFAN) said that he had two versions of 10" rings and templates and he had sent me the wrong ones. He is cutting me a new template and rings this weekend and I should have them next week. However, I wanted to get these speakers back in service, so I decided to grind off the excess steel. I had two options:

1. Do the grinding myself (hours).

2. Take the template to the machine shop at work and have it ground in about five minutes.

Actually, option 2 was less efficient and more time consuming because, by the time I spent an hour (round-trip) going to/from my work location, then tracked down someone in the machine shop to do the grinding, then answered 689 questions about why I needed this done and what I was going to use it for, then listened to them explain how much other work was ahead of me, probably four or five days would have expired and the replacement rings and template from Larry would already be here.

Figure 7. Passive radiator laid on top of its steel ring.

I used a compass to draw a circle 1/16" from the edge of the template, then a Dremel with grinding stone attachment #8193 was used to grind off the excess steel. It took two and one-half hours (four 30 minute sessions) with rest breaks in between grinding sessions to allow the Dremel and my hands to rest.

Figure 8. Setting up to draw a ring around the template for a grinding guide.

Figure 9. Me grind you long time. Of course I didn't do the real grinding in the dark. I dimmed the lights so the sparks would show up

better for this picture.

The grinding was tedious, but it was a labor of love. I fully expected that the end result would be Such Good Sound that all my toil and tedium would be quickly forgotten the moment I fired up my "new" CRS+'s.:)

Figure 10. The adjusted template worked as required. I numbered sections of the template so that I always knew where I was as I was

grinding.

Figure 11. The famous, "temperamental" CRS+ passive radiator grille gets sized up for drilling.

How many of you CRS owners have passive radiators where one, or more, or all of the screws are going in at an angle instead of straight in? This is due to the fact that care was often not used to perfectly align the holes in the metal passive radiator grille with the holes in the passive radiator basket rim. This misalignment often caused the passive radiator/grille screws to be deflected and go into the wood cabinet at an angle. I laid the passive grille on top of the passive ring and placed dots of red paint where the new holes were to be drilled. The grille was secured to a 12" x 12" piece of scrap wood with two of the original wood screws to hold it for drilling. The rim edges of the CRS grilles were often cut out of round. This could cause problems if the grille holes were not reinstalled with the original orientation to match the corresponding cabinet holes. I marked the "top" of the ring and the "top" of the grille so that they both would maintain proper orientation at installation.

Figure 12. Finished CRS+ passive radiator and grille installation, with an optimal eight button head hex screws instead of the standard

four wood screws.

Figure 13. Finished driver installation with four 8/32 socket head cap screws (just like the SRS's use) rather than four wood screws.

I thought this mod on one pair of my "baby SDA's" would be as easy as a day at the beach, but it turned out to be more like a long day at work. It was worth it.:) This pair of 1989 version CRS+'s is clad in the elegant black oak veneer with satin finish. The following modifications were previously performed:

1. Crossover upgrade with Mills MRA-12 resistors, Clarity Cap and AudioCap polypropylene capacitors, "4.1TL" modification which allowed the use of the RD-0198 (SL3000 replacement) tweeter.

2. Mortite seals for tweeters, drivers and passive radiators.

3. Custom heavy gauge SDA interconnect cable.

4. Replacement of SL2000 tweeters with RD-0198 tweeters.

5. Vampire binding posts.

6. Foam rubber damping material on the driver and passive radiator baskets.

My experience installing rings in my SDA SRS 1.2TL's is discussed here. My experience installing rings in my SDA SRS's is discussed here.

Based on my previous experiences, I expected this modification to take about two hours. It actually took a little over five hours due to some unforeseen difficulties. This time included a half hour to install Dynamat Extreme vibration damping material on the driver and passive radiator baskets.

Figure 1. CRS+ cabinets prepped for surgery.

Figure 2. Foam rubber insulation on the metal baskets was replaced with Dynamat Extreme.

Some Surprises

Installation of the driver rings was easy and went as expected. I was surprised by the brittleness of the cabinet material. Figures 3 and 4 show the severe cracking that occurred during the drilling of two of the driver ring holes. Most of the other drilled holes exhibited much less severe, or no, cracking. The grade of MDF used for the CRS+ cabinet material is a lot different from that used in the SRS series SDA's.

Figure 3. Cracked driver hole on right CRS+.

Figure 4. Cracked driver hole on left CRS+.

Two of the driver cutouts were close to cabinet corners that had about 10.8 pounds of glue on them. Some of that glue needed to be cut and pried off to clear space for the rings (figure 5). I used a very sharp box cutter to slice through the glue and a large flat screwdriver to pry it off.

Figure 5. Gobs and gobs of glue in the corners, some of which had to be cut away to provide space for this ring.

Figure 6 shows the amount of glue that had to be removed near one cabinet corner, the toothpicks that were formerly used to "fix" five stripped driver screw holes and some of the cracked off MDF material that resulted from drilling. Considering the brittleness of the cabinet material, it is easy to see why the screw holes were so prone to stripping. Fortunately, the rings make that concern a thing of the past.:)

Figure 6. Top to bottom: glue that needed to be removed, "toothpick fixes" that were used to secure stripped driver screw holes, cracked

off cabinet material due to drilling.

When I started to install the ring for one of the passive radiators, I discovered that the drilling template was too big to fit inside the passive radiator cabinet cutout. I measured the cabinet cutout diameter as 10-10/64", the passive radiator rim diameter as 10-6/64", the ring diameter as 10-15/64" and the drilling template diameter as 10-15/64". The drilling template diameter should have been about the same as the passive radiator rim diameter, but it (and the ring diameter) exceeded it by a little over 1/16th" all around (figure 7). The larger ring diameter was not an issue since the ring holes lined up with the passive radiator rim holes and the ring was going inside the cabinet.

When I taped the over-sized template over the passive radiator cutout, I saw that four of the template holes lined up perfectly with the four screw holes in the cabinet cutout. The template's internal diameter also matched the internal diameter of the cabinet cutout. Therefore, the only thing wrong was the template's external diameter.

Larry (forum member TOOLFORLIFEFAN) said that he had two versions of 10" rings and templates and he had sent me the wrong ones. He is cutting me a new template and rings this weekend and I should have them next week. However, I wanted to get these speakers back in service, so I decided to grind off the excess steel. I had two options:

1. Do the grinding myself (hours).

2. Take the template to the machine shop at work and have it ground in about five minutes.

Actually, option 2 was less efficient and more time consuming because, by the time I spent an hour (round-trip) going to/from my work location, then tracked down someone in the machine shop to do the grinding, then answered 689 questions about why I needed this done and what I was going to use it for, then listened to them explain how much other work was ahead of me, probably four or five days would have expired and the replacement rings and template from Larry would already be here.

Figure 7. Passive radiator laid on top of its steel ring.

I used a compass to draw a circle 1/16" from the edge of the template, then a Dremel with grinding stone attachment #8193 was used to grind off the excess steel. It took two and one-half hours (four 30 minute sessions) with rest breaks in between grinding sessions to allow the Dremel and my hands to rest.

Figure 8. Setting up to draw a ring around the template for a grinding guide.

Figure 9. Me grind you long time. Of course I didn't do the real grinding in the dark. I dimmed the lights so the sparks would show up

better for this picture.

The grinding was tedious, but it was a labor of love. I fully expected that the end result would be Such Good Sound that all my toil and tedium would be quickly forgotten the moment I fired up my "new" CRS+'s.:)

Figure 10. The adjusted template worked as required. I numbered sections of the template so that I always knew where I was as I was

grinding.

Figure 11. The famous, "temperamental" CRS+ passive radiator grille gets sized up for drilling.

How many of you CRS owners have passive radiators where one, or more, or all of the screws are going in at an angle instead of straight in? This is due to the fact that care was often not used to perfectly align the holes in the metal passive radiator grille with the holes in the passive radiator basket rim. This misalignment often caused the passive radiator/grille screws to be deflected and go into the wood cabinet at an angle. I laid the passive grille on top of the passive ring and placed dots of red paint where the new holes were to be drilled. The grille was secured to a 12" x 12" piece of scrap wood with two of the original wood screws to hold it for drilling. The rim edges of the CRS grilles were often cut out of round. This could cause problems if the grille holes were not reinstalled with the original orientation to match the corresponding cabinet holes. I marked the "top" of the ring and the "top" of the grille so that they both would maintain proper orientation at installation.

Figure 12. Finished CRS+ passive radiator and grille installation, with an optimal eight button head hex screws instead of the standard

four wood screws.

Figure 13. Finished driver installation with four 8/32 socket head cap screws (just like the SRS's use) rather than four wood screws.

Proud and loyal citizen of the Digital Domain and Solid State Country!

Post edited by DarqueKnight on

Comments

-

Listening Evaluation

Figure 14. Setting up for comparative listening. Another pair of hot-rodded, but un-ringed CRS+'s is at the right. We sure do have a good

time at the SDA Shrine...where 20+ year old SDA's, like fine wine, get better with age.

Listening evaluations were conducted with my home theater system, since the equipment there is more similar to the office system in which the modified CRS+'s will be used:

1. Pioneer Elite BDP-09FD Blu-ray disc player.

2. Sony TA-P9000ES analog 5.1 multi-channel preamp.

3. Adcom GFA-5500 power amp (200 wpc @ 8 ohms).

4. Monster Cable Z2 Reference speaker cables.

5. Monster Cable Z100i interconnects.

Prior to the ring modification, the black oak CRS+'s were compared to another hot-rodded pair of CRS+'s that were finished in a luxurious custom teak veneer. I could not detect a sonic difference between them. After modification, the CRS+'s sounded not only louder, but bigger. They now sounded more like a pair of medium tower speakers rather than large bookshelf speakers. I could feel more vibration coming through the sofa. I heard more rumble, growl and detail in the bass notes. I heard more overall clarity and detail. After listening for a while, I put the un-ringed teak veneer CRS+'s in place. The sonic effect was analogous to dimming the lights in a room: Some bass details were diminished. Some disappeared. There was an apparent overall veiling of the sound and the apparent sound level sharply decreased. There was no difference between the sound stage dimensions and image placement of the ringed and un-ringed CRS+'s. There was a night and day difference in clarity, apparent sound level and bass performance.

Figure 15. Awwwww...it sucks to be you. The un-ringed CRS+'s are disappointed at their new status as "SDA step-children". It's only

temporary.

I am considering not installing rings in one of the teak CRS+ pairs to use for demo purposes to show the dramatic difference the rings make. The degree of sonic improvement brought by the rings was greater in the CRS+'s than in the SDA SRS's and SDA SRS 1.2TL's.DarqueKnight wrote: »It is always amazing when I hear how much musical information was being lost due to vibration at the driver/cabinet interface...

It may seem like overkill to put such a nice pair of speakers in an office rig, but I prefer "true stereo" even while at work. The black oak CRS+'s are used in my office rig along with mint condition vintage electronics from the 1980's and 1990's:

1. Nakamichi CA-5AII preamp.

2. Yamaha CDX-1110U CD player.

3. Yamaha TX-1000U digital tuner.

4. Adcom GFA-555 Mk II power amp (200 wpc @ 8 ohms).

5. Signal Cable MagicPower power cords.

6. Monster Cable Z2 Reference speaker cable.

7. Monster Cable Z100i interconnects.

I should have seen it coming, but I was pleasantly surprised at the significant increase in low level clarity, detail and presence. This is even more important in my office system application since I usually have to listen at low volume.

Related Threads

Link: Improved SDA Interconnect Cables

Link: 4.1TL Modification For 1989 Version CRS+

Link: Steel Driver And PR Rings For The Original SDA SRS

Link: Steel Rings For the SDA SRS 1.2TL

Link: Mortite Speaker Seals For SDA'sProud and loyal citizen of the Digital Domain and Solid State Country! -

Another excellent write up, and very timely as I just ordered the parts (thanks to the sale at Sonic Craft) for my pair of CRS+'s with the pin/blade interconnect.

I hadn't considered black oak before but it looks like a good choice.

I'll definitely be using this and your other upgrade thread for guidance.

What an amazing resource!

Thanks."The good thing about science is that it's true whether or not you believe in it." Neil deGrasse Tyson. -

I absolutely love the improvement the rings made on my 2Bs. It's nice to hear your impressions on a variety of different models."The secret of happiness is freedom. The secret of freedom is courage." Thucydides

-

As usual, nice write up.

I had the same issues with some flaking/chipping when drilling the holes in the CRS+ cabinets. This is because they are particle board, where as the TL cabinets appear to be MDF. I used a quick set wood epoxy to repair the damages before mounting the drivers as I wanted a defect free mating surface all around.

I also had the same issue with the PR template. I took the template for the 6.5 drivers, lined it up over one hole at a time, clamped it and drilled. This worked perfectly.

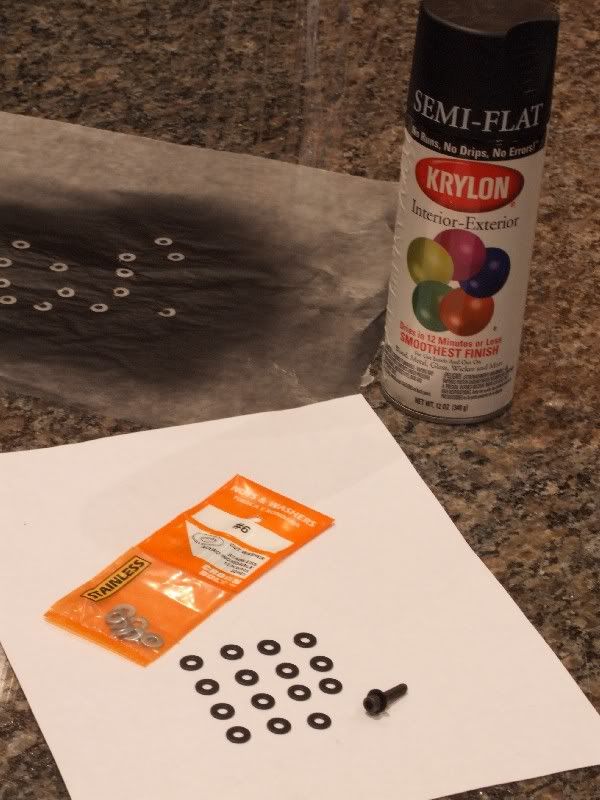

Previously I had drilled out the 4 extra holes in the mesh cover and cabinet to utilize all 8 of the holes in the PR basket. Instead of using the dome top screws Larry provided I used the cap screws with number 8 brass washers sprayed semi-flat black. I enlarged the holes in the mesh cover using my Dremel with a cut off wheel to remove the material.

Same results I'm sure, just another way of getting there.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

I had the same issues with some flaking/chipping when drilling the holes in the CRS+ cabinets. This is because they are particle board, where as the TL cabinets appear to be MDF. I used a quick set wood epoxy to repair the damages before mounting the drivers as I wanted a defect free mating surface all around.

I assumed it was a rough type MDF. From the front it looked like particle board, from the inside it looked like MDF.

I thought about repairing the cracks, and I definitely would have if I wasn't using Mortite seals. I just put a little extra dab of Mortite on the two heavily cracked areas. If I recall correctly, you are still using the stock foam seals?Previously I had drilled out the 4 extra holes in the mesh cover and cabinet to utilize all 8 of the holes in the PR basket. Instead of using the dome top screws Larry provided I used the cap screws with number 8 brass washers sprayed semi-flat black. I enlarged the holes in the mesh cover using my Dremel with a cut off wheel to remove the material.

Another tool I like to use for enlarging small holes in metal is the Dremel chain saw sharpening stone, part #454.Proud and loyal citizen of the Digital Domain and Solid State Country! -

I thought about repairing the cracks, and I definitely would have if I wasn't using Mortite seals. I just put a little extra dab of Mortite on the two heavily cracked areas.

That'll work.If I recall correctly, you are still using the stock foam seals?

The short story....I tried the Mortite and went back to the stock seals because I feel the sound is better using them with the rings.

If you want the long story, I'll call you.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

I completed the installation of steel rings on my other two pairs of SDA CRS+'s...and they are now back in the "Magic Closet" awaiting future use.:)

Figure 1. Prior to surgery: The first of two CRS+ pairs, both of which are covered in a luxurious custom teak veneer finish.

Figure 2. Lemme drill you. The replacement 10" passive radiator drilling template fit perfectly.

Figure 3. A small crack habit. The CRS+ particle board cabinets are very prone to cracking and crumbling when drilled. The original wood

screws caused these cracks.

Figures 4-6 show the cracking that occurred on some holes during drilling. Due to the severity of these cracks, the missing wood was repaired with wood epoxy.

Figure 4. Cracking up: Passive radiator drill holes.

Figure 5. Cracking up: Driver drill hole.

Figure 6. Cracking up: Driver drill hole.

Figure 7. For the passive radiator, I added #6 size stainless steel washers to the screws. I also decided to use the socket head cap screws

(left) rather than the button head hex screws.

The head of the socket head cap screw is just a little larger than the passive radiator rim holes and is prone to punching through the rim holes when tightened down.

The head of the button head hex screw is much larger than the passive radiator rim holes, but in order to get perfect alignment between the passive radiator rim holes and the ring holes, I had to enlarge some of the passive radiator rim holes. I also had to enlarge some of the passive radiator grille holes for alignment with the ring holes. The socket head cap screw was preferred because the larger socket hole allowed more torque to be applied without the possibility of stripping the head. This is a concern when using Mortite speaker seals.

I decided to follow F1nut's suggestion and use a combination of metal washer and socket head cap screw rather than the button head hex screw alone. Rather than the #8 brass washers F1nut used, I chose smaller (and stronger and harder) #6 stainless steel washers. The #6 metal washers were the perfect size to fit the shaft diameter of both the socket head cap screws. The #6 washers were also the perfect size to fit into the notches cut into the rubber surrounds.

Larry (TOOLFORLIFEFAN) had sent a lot of extra socket head cap screws. I had just enough to go back and replace all of the button head hex screws

in the passive radiators of my other three pairs of SDA's.

I ordered additional 3/4" socket head cap screws from Palmer Bolt & Supply Co. (www.palmerbolt) for 6 cents each (+ 6.96 shipping). The Palmer part number is SHCS008C0075STPN. These will be used on the tweeters when Larry makes the tweeter plates available.

Figure 8. The #6 washers were painted with Krylon semi-flat black (#1613)

Figure 9. Completed passive radiator/grille installation secured with socket head cap screws and washers.

On two of the grilles, the raised portion near one rim hole had to be slightly dented inward to provide more room to clear the washer. I clamped the grille to a 12" x 12" board and used a hammer and a screwdriver with a 5/16" wide blade to gently push in the metal.

Because of all the adjustments that were particular to specific holes on the grille rim, the orientation of the grill would need to be maintained if the grille were removed and reinstalled. A red paint dot was placed on the cabinet above the topmost screw and on the passive radiator below the topmost screw (figure 10).

Figure 10. Passive radiator orientation dots.

Figure 11. The teak veneered CRS+'s have Cardas CCGR binding posts. This picture has nothing to do with this ring installation thread, I

just wanted to mention this because they are pretty.:)

Figure 12. Play time after modification.

All of my SDA's have now been ringed, Mortited, Dynamatted, silk dome tweetered, wire-wound resitored, premium film capacitored, Cardas or Vampire binding posted, silky grille clothed and custom SDA cabled.Proud and loyal citizen of the Digital Domain and Solid State Country! -

I did say #8 didn't I.......my mistake, they were #6.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

Looks like the pics are coming back...

-

Glad I saw this. I assumed that the PR grills were precision made and drilled. The funny thing is one of the cabs on my CRS+ appears to be MDF with a front baffle of particle board; the other cab is plywood with a particle board MDF."Science is suppose to explain observations not dismiss them as impossible" - Norm on AA; 2.3TL's w/sonicaps/mills/jantzen inductors, Gimpod's boards, Lg Solen SDA inductors, RD-0198's, MW's dynamatted, Armaflex speaker gaskets, H-nuts, brass spikes, Cardas CCGR BP's, upgraded IC Cable, Black Hole Damping Sheet strips, interior of cabinets sealed with Loctite Power Grab, AI-1 interface with 1000VA A-L transformer

-

Pio Elete Pro 520

Panamax 5400-EX

Sunfire TGP 5

Micro Seiki DD-40 - Lyra-Dorian and Denon DL-160

PS Audio GCPH phono pre

Sunfire CG 200 X 5

Sunfire CG Sig 405 X 5

OPPO BDP-83 SE

SDA SRS 1.2TL Sonicaps and Mills

Ctr CS1000p

Sur - FX1000 x 4

SUB - SVS PB2-Plus

Workkout room:

Sony Bravia XBR- 32-Inch 1080p

Onkyo TX-DS898

GFA 555

Yamaha DVD-S1800BL/SACD

Ft - SDA 1C

Not being used:

RTi 38's -4

RT55i's - 2

RT25i's -2, using other 2 in shop

LSI 15's

CSi40

PSW 404 -

Proud and loyal citizen of the Digital Domain and Solid State Country!

-

DarqueKnight wrote: »

Yes, a lot were missing in action, some still arePio Elete Pro 520

Panamax 5400-EX

Sunfire TGP 5

Micro Seiki DD-40 - Lyra-Dorian and Denon DL-160

PS Audio GCPH phono pre

Sunfire CG 200 X 5

Sunfire CG Sig 405 X 5

OPPO BDP-83 SE

SDA SRS 1.2TL Sonicaps and Mills

Ctr CS1000p

Sur - FX1000 x 4

SUB - SVS PB2-Plus

Workkout room:

Sony Bravia XBR- 32-Inch 1080p

Onkyo TX-DS898

GFA 555

Yamaha DVD-S1800BL/SACD

Ft - SDA 1C

Not being used:

RTi 38's -4

RT55i's - 2

RT25i's -2, using other 2 in shop

LSI 15's

CSi40

PSW 404 -

Pio Elete Pro 520

Panamax 5400-EX

Sunfire TGP 5

Micro Seiki DD-40 - Lyra-Dorian and Denon DL-160

PS Audio GCPH phono pre

Sunfire CG 200 X 5

Sunfire CG Sig 405 X 5

OPPO BDP-83 SE

SDA SRS 1.2TL Sonicaps and Mills

Ctr CS1000p

Sur - FX1000 x 4

SUB - SVS PB2-Plus

Workkout room:

Sony Bravia XBR- 32-Inch 1080p

Onkyo TX-DS898

GFA 555

Yamaha DVD-S1800BL/SACD

Ft - SDA 1C

Not being used:

RTi 38's -4

RT55i's - 2

RT25i's -2, using other 2 in shop

LSI 15's

CSi40

PSW 404 -

My pictures are hosted on my Photobucket account. It appears that Vanilla has not gotten around to relinking all the attachments in various threads.

I checked one of my old threads that I knew had pic and pdf attachments and they are all there.

http://forum.polkaudio.com/discussion/73796/sda-polyswitches-are-nasty/p1Proud and loyal citizen of the Digital Domain and Solid State Country! -

That's good to know, maybe they will get all of them back. Your posts have helped me a lot, as well as posts from several others. The "how to" posts with photos are great.

When I joined I didn't know what a SDA was, I now have 6 sets.

Kind of hard not to spend money once you start learning.Pio Elete Pro 520

Panamax 5400-EX

Sunfire TGP 5

Micro Seiki DD-40 - Lyra-Dorian and Denon DL-160

PS Audio GCPH phono pre

Sunfire CG 200 X 5

Sunfire CG Sig 405 X 5

OPPO BDP-83 SE

SDA SRS 1.2TL Sonicaps and Mills

Ctr CS1000p

Sur - FX1000 x 4

SUB - SVS PB2-Plus

Workkout room:

Sony Bravia XBR- 32-Inch 1080p

Onkyo TX-DS898

GFA 555

Yamaha DVD-S1800BL/SACD

Ft - SDA 1C

Not being used:

RTi 38's -4

RT55i's - 2

RT25i's -2, using other 2 in shop

LSI 15's

CSi40

PSW 404 -

I too found the CRS+ PR grills a pita to install with the rings. Like the posts above, the grill mounting holes had to be enlarged and washers used. The button head screws that came with the ring kit worked fine for me. I got black oxide washers from http://www.albanycountyfasteners.com/. They have a very large selection. Glad that some pictures are back.Speakers: Polk SDA-SRS xovers rebuilt by David, RDO194's, Dynamat, BH5, glued magnets, new cloth, custom aluminum terminal plates with Cardas posts and Speakon interconnect

Speaker Cables, Jumpers & Interconnect: DIY Douglas Connection

Power Amp: Sunfire Architect's Choice Series II

Preamp: Adcom GFP-750

SACD/CD: Oppo BDP-95

Tuner: Sansui TU-717

TT: Technics SL-MA1

Phono Pre: Emotiva XPS-1

Music Server: Mac Mini w/JRiver - iPad w/JRemote

DAC: Eastern Electric MiniMax Plus

Other Polks: SDA: 1A, 1C, 2B, CRS+ / Monitor: 10A, 5jr, 4 / RT5 -

DarqueKnight,

Thank you for this post. I have a newly acquired set of CRS+s, and this gives me a great bit of info to consider as I move forward on upgrades.2.3TL's - Living Room

CRS+'s (4.1 TL's) - Office

SDA1C's - Famdamly Rm

SDA1C's - Master Bedroom -

^^^spam2-channel: Modwright KWI-200 Integrated, Dynaudio C1-II Signatures

Desktop rig: LSi7, Polk 110sub, Dayens Ampino amp, W4S DAC/pre, Sonos, JRiver

Gear on standby: Melody 101 tube pre, Unison Research Simply Italy Integrated

Gone to new homes: (Matt Polk's)Threshold Stasis SA12e monoblocks, Pass XA30.5 amp, Usher MD2 speakers, Dynaudio C4 platinum speakers, Modwright LS100 (voltz), Simaudio 780D DAC

erat interfectorem cesar et **** dictatorem dicere a -

txcoastal1 wrote: »^^^spam

A little late to the party, wouldn't you say...?!2.3TL's - Living Room

CRS+'s (4.1 TL's) - Office

SDA1C's - Famdamly Rm

SDA1C's - Master Bedroom