Easy (ish) DIY storage for CD/DVD.

daddyjt

Posts: 3,113

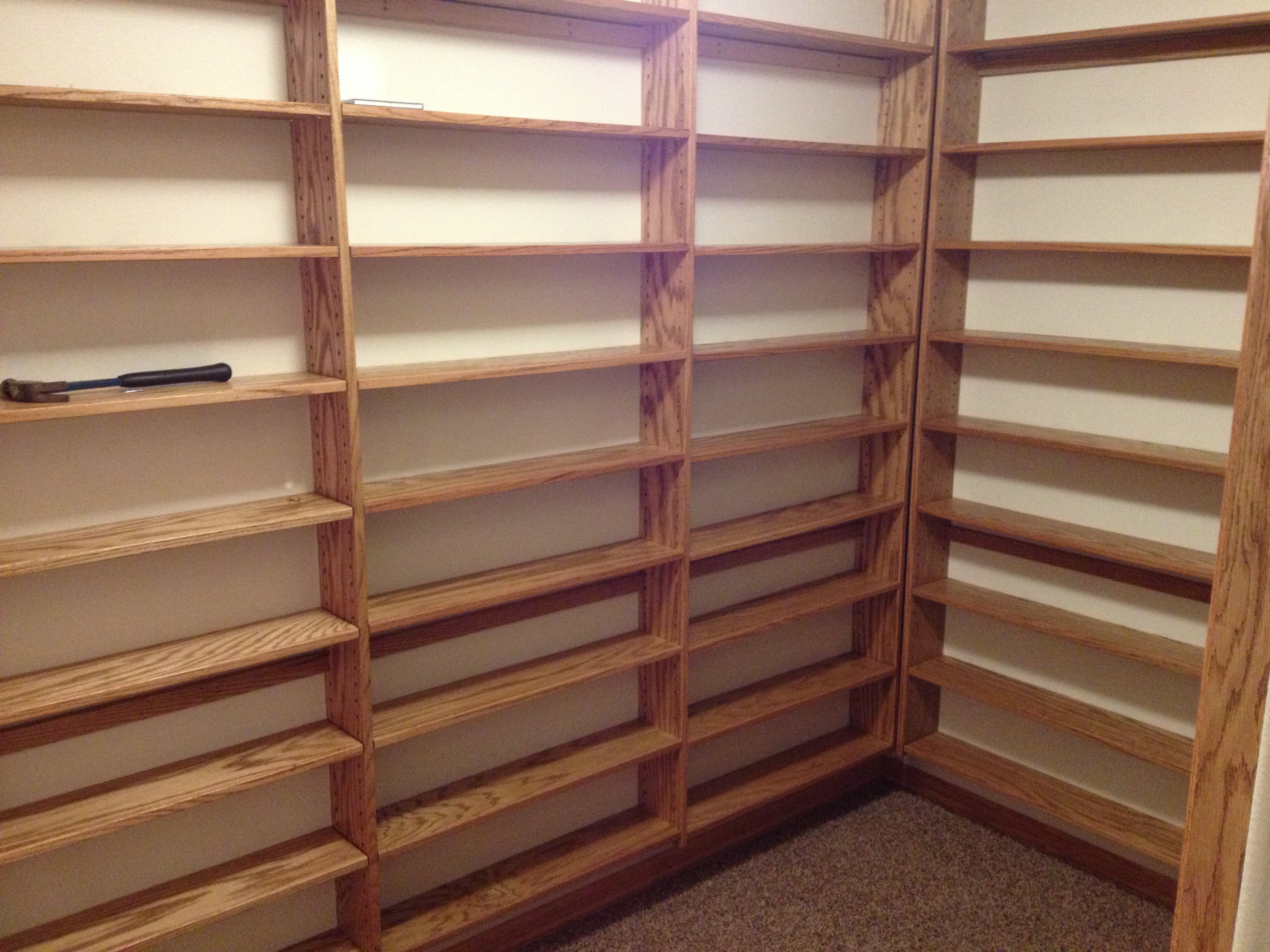

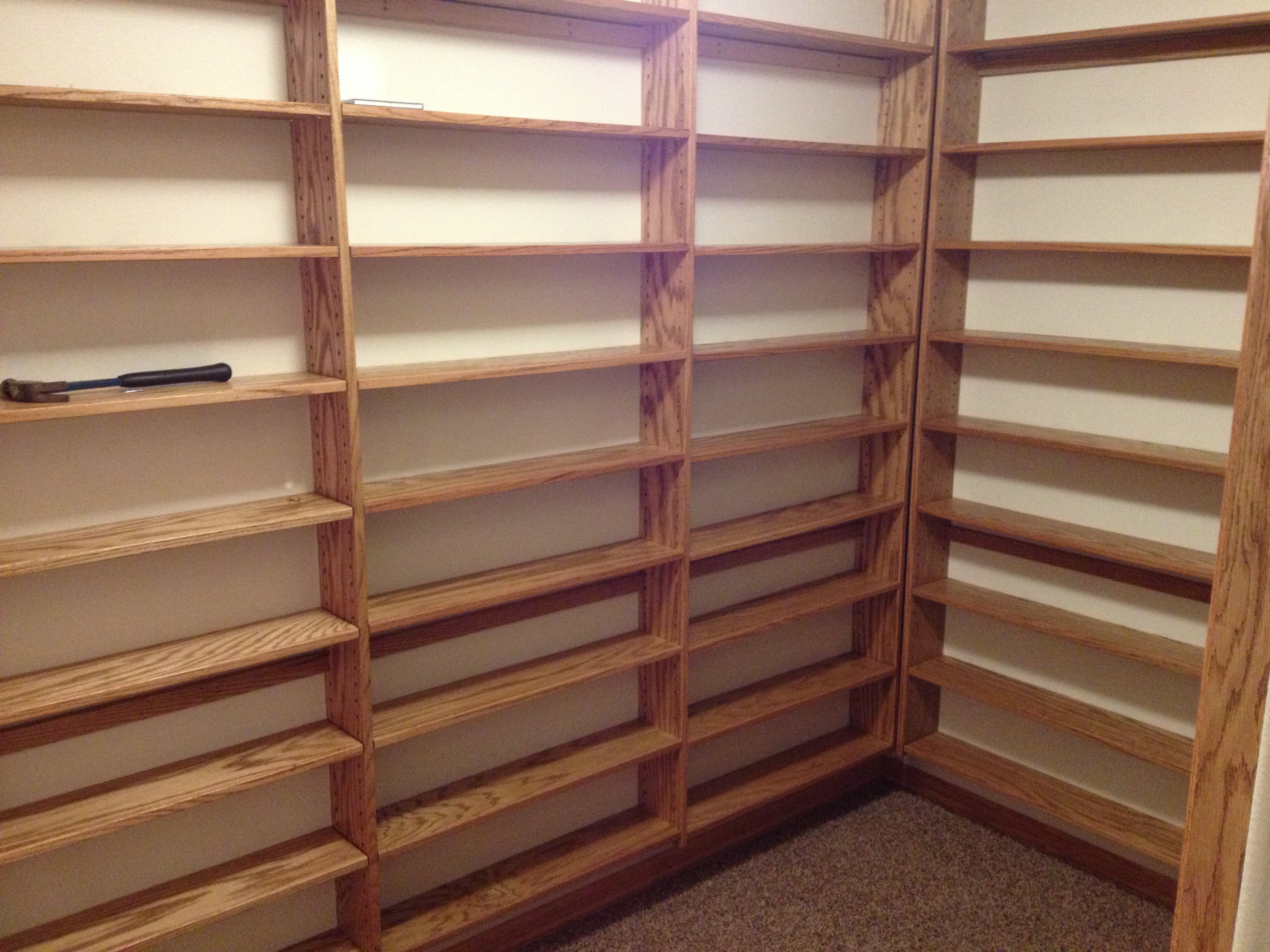

About 15 years ago I ran out of space in the five (5) bookcases I was using for CD/DVD storage. I figured there had to be a better way, and after a bit of thinking, I came up with it. On-wall, only 6” deep, adjustable shelf height, and inexpensive and easy to build.

With the expansion of my library into 4k discs, I am adding a 60”x42” chunk of the shelving In my current media room (6’ X 8’ walk in closet). I thought I’d document the construction process here, for anyone that may wish for a similar storage solution.

The system itself consists of 1”x2” mounting rails (x2), and 6” strips of 3/4” oak plywood with screen molding to cover the edge for the vertical supports and the individual shelves. I’ve included a few photos below from my original build, but I’ll do a thorough step-by-step with the current build.

Step one is to source a sheet of 3/4” oak plywood (or whatever wood you prefer), screen molding and 1”x2”. I must say, I was shocked at the increase in oak plywood pricing - last time I bought it I remember paying around $40 a sheet. No so any more - try $96 a sheet!

Anyway, accounting for the 1/4” thickness of the screen molding on the edge, rip the plywood into 5.75” strips to achieve the 6” overall depth. These cuts are so easy, I don’t even drag out the table saw, lol…

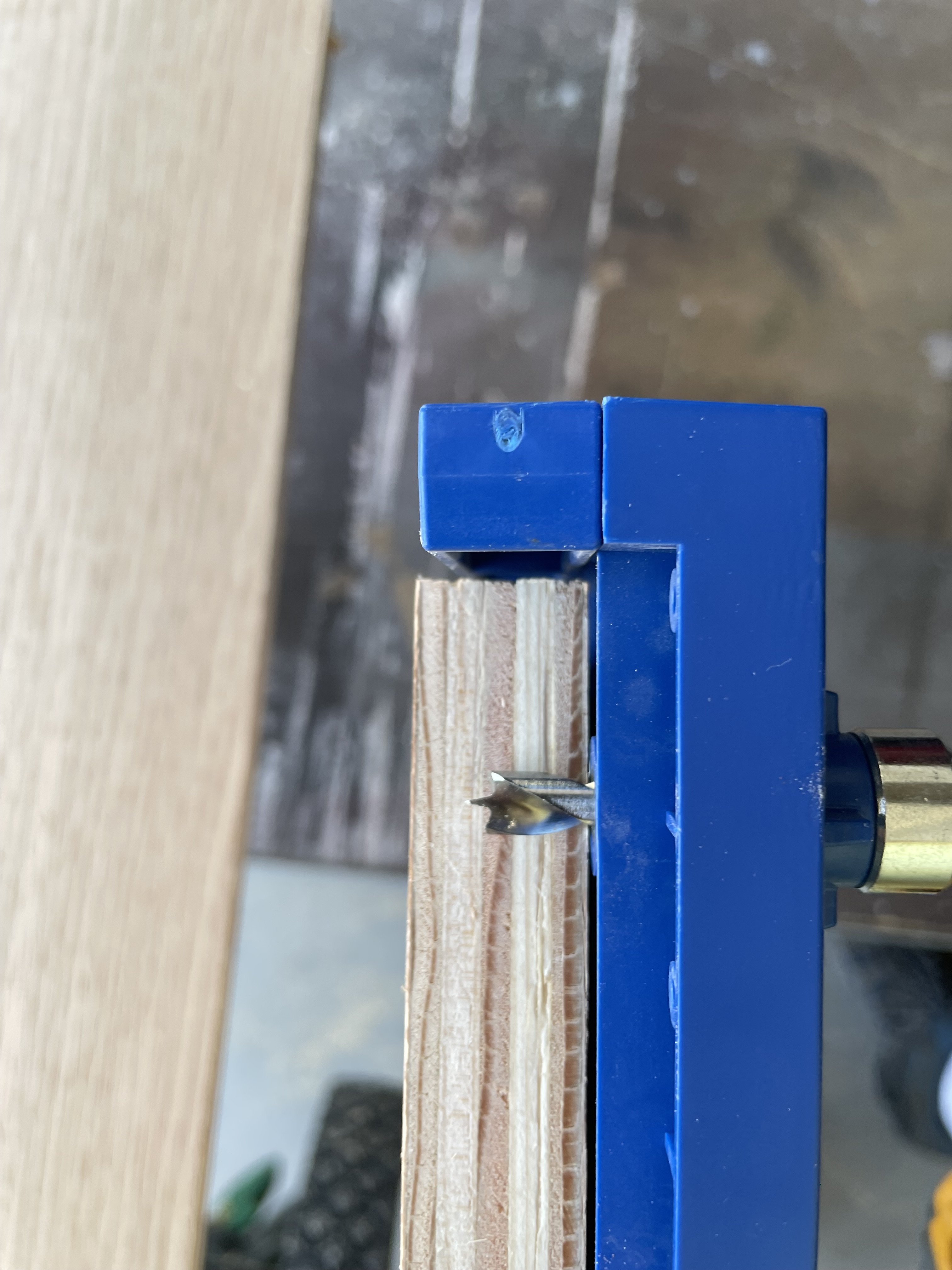

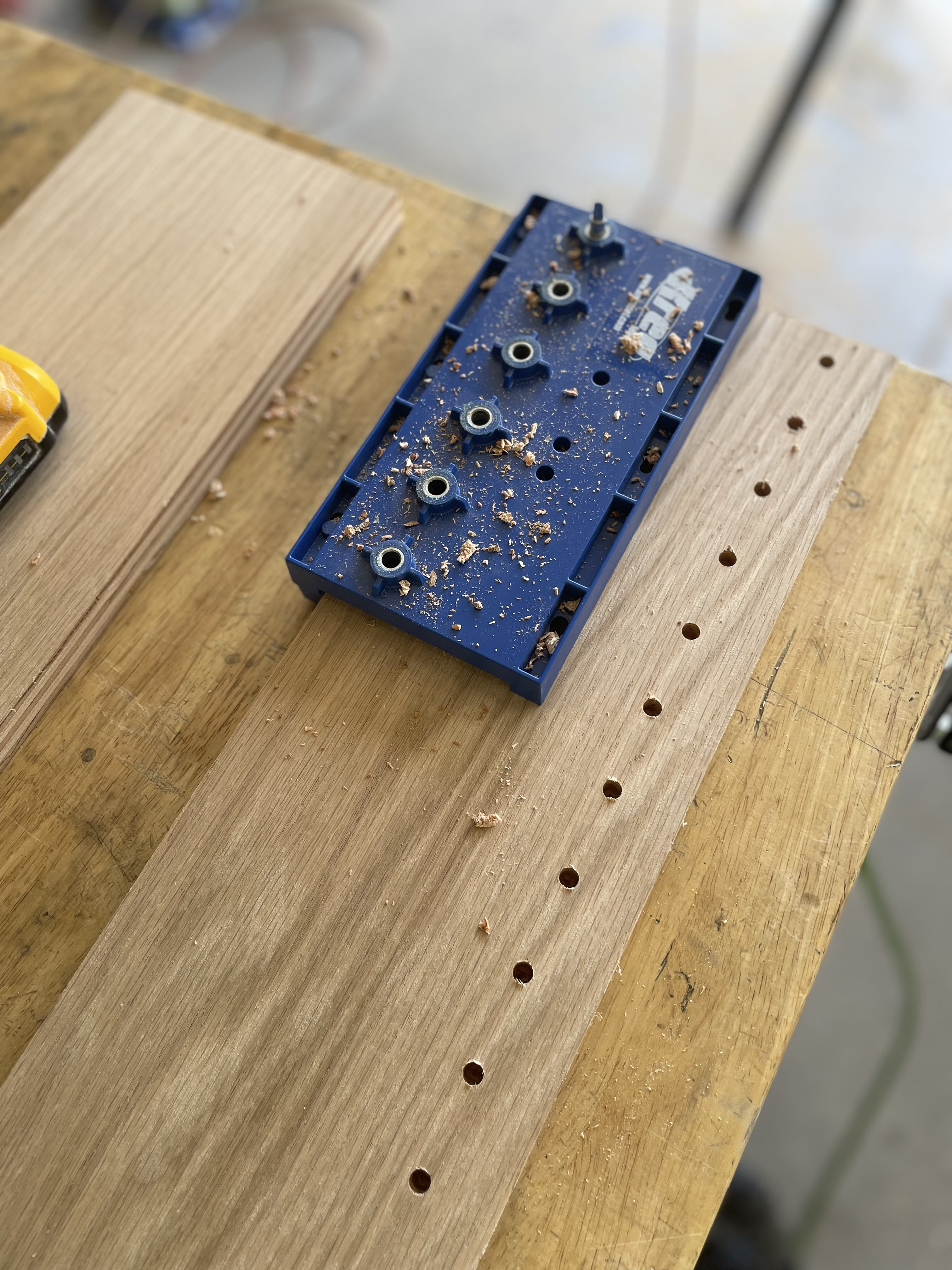

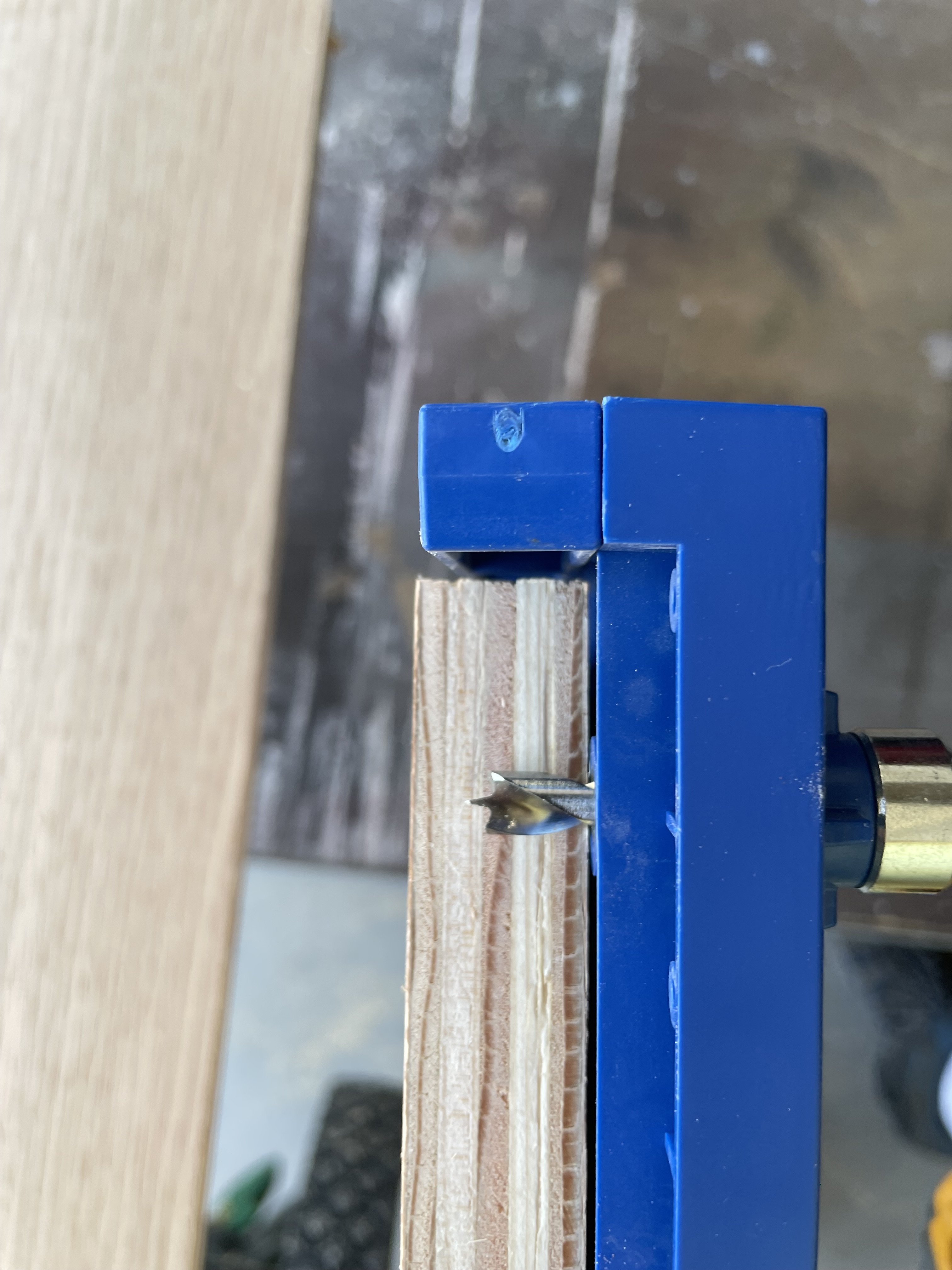

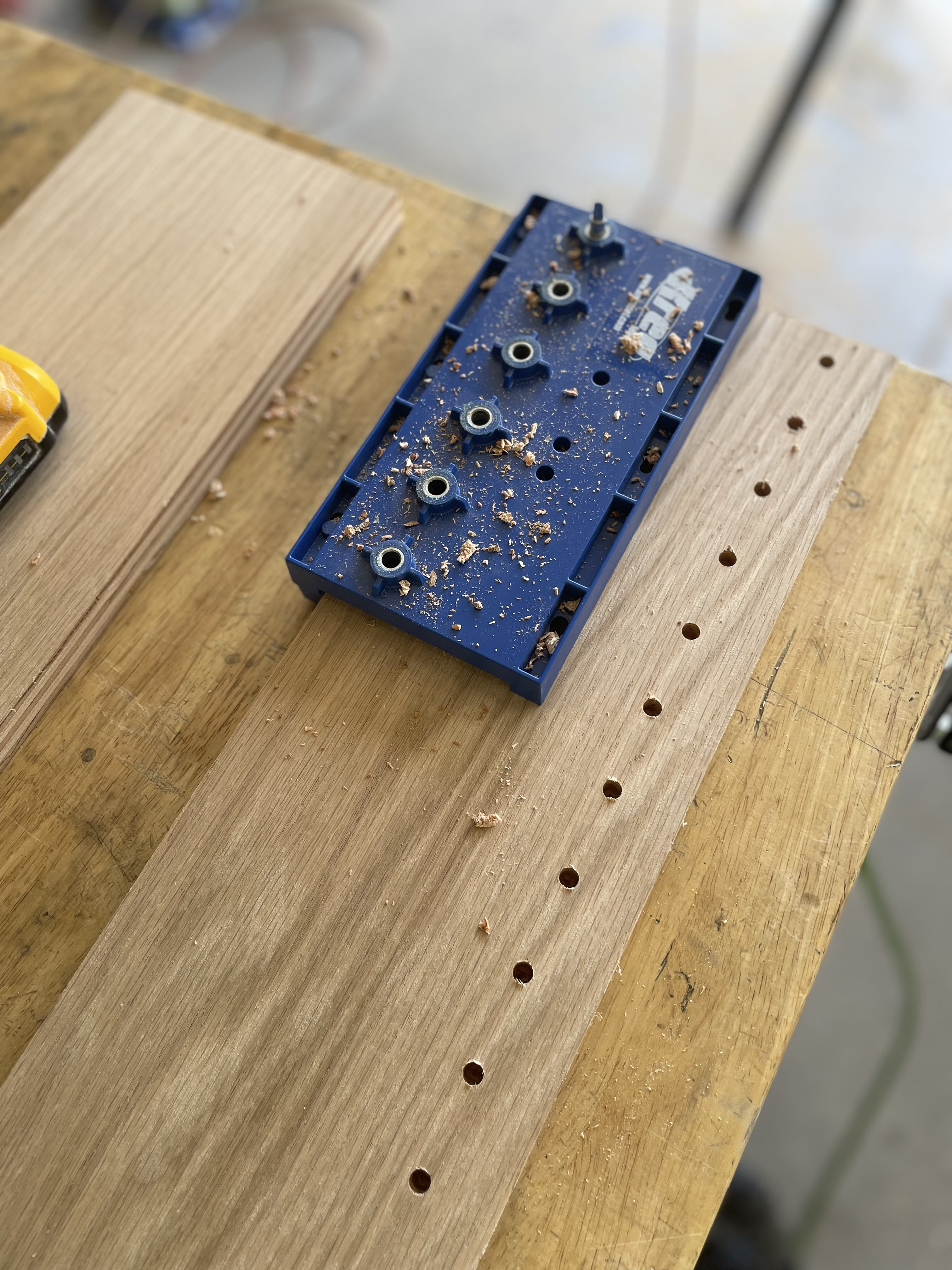

Next, cut 2 (or more) of the strips to the overall height you desire for your shelving unit - in my case, for this unit I’m going with 60” (Al the other shelving in my room is 96”, or the full 8’). These will be the vertical or side supports. In order to make the shelving fully adjustable, these need to have a series of holes drilled for the shelf support pegs. These hole need to be perfectly spaced, drilled perfectly perpendicular, and be a perfect consistent depth on BOTH boards. Luckily, Kreg makes a jig for this that is quite affordable and easy to use…

Work these two strips together and symmetrically, so that your shelves will be level. I mark the top of each, and start my holes at the exact same height. The bit included with the jig has an adjustable stop collar - set it to the correct depth and drill the starter hole at the top. Then position the jig with the included pin and drill the remaining holes. Move the jig down, place the pin and repeat. It’s not near as monotonous as it sounds, and it goes pretty fast.

Next is cutting the individual shelves. In my case, I want 42” overall width, so subtracting the 3/4” (x2) for the side panels gives me 40.5”. Cut and build a couple more shelves than you think you’ll need! You already have everything out - just make a couple extras, as you never know what your future needs will be. You’ll thank me later. Also cut your 1”x2” to the overall width (42” for this one) and all the screen molding for the exposed edges.

There are a couple different ways to mount the screen molding to the edges. Glue and clamp, clue and finish nail (with nail-set and wood putty), or glue and pin nail with an air nailer - this is the method I use.

Next is perhaps the most precise part of construction - the cutting of the 1”x2” notches in the vertical supports. It is critical that they be cut in the exact same place on all verticals supports being made for a continuous run, or it will be impossible to have level shelves. For these reasons, I stack the vertical supports and cut them at the same time.

Next up is sanding. DO NOT skimp on sanding! It takes a bit of time, but few things can make or break a project quite like sanding (or lack thereof). I do a full pass with 120 on the random orbital, then a pass with the 1/3 sheet at 180, then a final pass with 220 on the 1/3 sheet. I like the random orbital on initial passes, but not for the final.

With sanding done, SWEEP UP YOUR WORK AREA! This will minimize kicking up dust and particles during the finishing process. I like to hit all surfaces with the air compressor to blow off as much dust as possible. This also gets dust out of the grain, which will really make the grain stand out when stained/finished. After the compressor treatment, a tac cloth is a good idea, right before finishing.

For this project, I’m not using a stain, just a satin polyurethane finish. For a project like this, I just use a foam brush and toss it when done. Long strokes with the grain, and careful to avoid drips/sags…

24 hours (depending on temp/humidity - but if ANY tac remains, WAIT!) later, a good rubbing with semi-coarse steel wool is essential to smooth the wood down. DO NOT use steel wool if using a water-based finish!! After steel wool, tac cloth again and another coat of polyurethane.

After the second coat of polyurethane has dried, a second steel wool treatment with fine (000 or 0000) and another tac cloth rub.

Now that all the wood cutting and finishing is done, it’s time for construction. The key to the strength of this build lies here - the 1”x2” mounting boards are screwed into the notches in the vertical supports FROM THE BACK SIDE, before the unit is mounted to the wall, then the entire assembly (sans shelves) is mounted to the wall.

The completed frame is quite light, allowing it to be positioned and mounted to the wall. Take care to make sure it is both level AND square when mounting! Once it is mounted, populate the shelves to the desired height. One of the only potential annoyances with this system is this: If a shelf is positioned such that the 1”x2” wall support is contacting the upper half of your media, it will allow for the bottom portion of your media to push in farther than the top, where it is contacting the 1”x2”. In this case, simply cut a spare 1x2 to the width of your shelf and lay it at the bottom/back of the shelf, so that the media contacts a 1x2 on the top and bottom.

With the expansion of my library into 4k discs, I am adding a 60”x42” chunk of the shelving In my current media room (6’ X 8’ walk in closet). I thought I’d document the construction process here, for anyone that may wish for a similar storage solution.

The system itself consists of 1”x2” mounting rails (x2), and 6” strips of 3/4” oak plywood with screen molding to cover the edge for the vertical supports and the individual shelves. I’ve included a few photos below from my original build, but I’ll do a thorough step-by-step with the current build.

Step one is to source a sheet of 3/4” oak plywood (or whatever wood you prefer), screen molding and 1”x2”. I must say, I was shocked at the increase in oak plywood pricing - last time I bought it I remember paying around $40 a sheet. No so any more - try $96 a sheet!

Anyway, accounting for the 1/4” thickness of the screen molding on the edge, rip the plywood into 5.75” strips to achieve the 6” overall depth. These cuts are so easy, I don’t even drag out the table saw, lol…

Next, cut 2 (or more) of the strips to the overall height you desire for your shelving unit - in my case, for this unit I’m going with 60” (Al the other shelving in my room is 96”, or the full 8’). These will be the vertical or side supports. In order to make the shelving fully adjustable, these need to have a series of holes drilled for the shelf support pegs. These hole need to be perfectly spaced, drilled perfectly perpendicular, and be a perfect consistent depth on BOTH boards. Luckily, Kreg makes a jig for this that is quite affordable and easy to use…

Work these two strips together and symmetrically, so that your shelves will be level. I mark the top of each, and start my holes at the exact same height. The bit included with the jig has an adjustable stop collar - set it to the correct depth and drill the starter hole at the top. Then position the jig with the included pin and drill the remaining holes. Move the jig down, place the pin and repeat. It’s not near as monotonous as it sounds, and it goes pretty fast.

Next is cutting the individual shelves. In my case, I want 42” overall width, so subtracting the 3/4” (x2) for the side panels gives me 40.5”. Cut and build a couple more shelves than you think you’ll need! You already have everything out - just make a couple extras, as you never know what your future needs will be. You’ll thank me later. Also cut your 1”x2” to the overall width (42” for this one) and all the screen molding for the exposed edges.

There are a couple different ways to mount the screen molding to the edges. Glue and clamp, clue and finish nail (with nail-set and wood putty), or glue and pin nail with an air nailer - this is the method I use.

Next is perhaps the most precise part of construction - the cutting of the 1”x2” notches in the vertical supports. It is critical that they be cut in the exact same place on all verticals supports being made for a continuous run, or it will be impossible to have level shelves. For these reasons, I stack the vertical supports and cut them at the same time.

Next up is sanding. DO NOT skimp on sanding! It takes a bit of time, but few things can make or break a project quite like sanding (or lack thereof). I do a full pass with 120 on the random orbital, then a pass with the 1/3 sheet at 180, then a final pass with 220 on the 1/3 sheet. I like the random orbital on initial passes, but not for the final.

With sanding done, SWEEP UP YOUR WORK AREA! This will minimize kicking up dust and particles during the finishing process. I like to hit all surfaces with the air compressor to blow off as much dust as possible. This also gets dust out of the grain, which will really make the grain stand out when stained/finished. After the compressor treatment, a tac cloth is a good idea, right before finishing.

For this project, I’m not using a stain, just a satin polyurethane finish. For a project like this, I just use a foam brush and toss it when done. Long strokes with the grain, and careful to avoid drips/sags…

24 hours (depending on temp/humidity - but if ANY tac remains, WAIT!) later, a good rubbing with semi-coarse steel wool is essential to smooth the wood down. DO NOT use steel wool if using a water-based finish!! After steel wool, tac cloth again and another coat of polyurethane.

After the second coat of polyurethane has dried, a second steel wool treatment with fine (000 or 0000) and another tac cloth rub.

Now that all the wood cutting and finishing is done, it’s time for construction. The key to the strength of this build lies here - the 1”x2” mounting boards are screwed into the notches in the vertical supports FROM THE BACK SIDE, before the unit is mounted to the wall, then the entire assembly (sans shelves) is mounted to the wall.

The completed frame is quite light, allowing it to be positioned and mounted to the wall. Take care to make sure it is both level AND square when mounting! Once it is mounted, populate the shelves to the desired height. One of the only potential annoyances with this system is this: If a shelf is positioned such that the 1”x2” wall support is contacting the upper half of your media, it will allow for the bottom portion of your media to push in farther than the top, where it is contacting the 1”x2”. In this case, simply cut a spare 1x2 to the width of your shelf and lay it at the bottom/back of the shelf, so that the media contacts a 1x2 on the top and bottom.

“Human beings are born with different capacities. If they are free, they are not equal. And if they are equal, they are not free.”

― Aleksandr Solzhenitsyn

― Aleksandr Solzhenitsyn

Comments

-

Very nice and excellent instructions.Political Correctness'.........defined

"A doctrine fostered by a delusional, illogical minority and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a t-u-r-d by the clean end."

President of Club Polk -

Awesome work!The Gear... Carver "Statement" Mono-blocks, Mcintosh C2800 Arcam AVR20, Oppo UDP-203 4K Blu-ray player, Sony XBR70x850B 4k, Polk Audio Legend L800 with height modules, L400 Center Channel Polk audio AB800 "in-wall" surrounds. Marantz MM7025 stereo amp. Simaudio Moon MiND2 Shunyata Triton

“When once a Republic is corrupted, there is no possibility of remedying any of the growing evils but by removing the corruption and restoring its lost principles; every other correction is either useless or a new evil.”— Thomas Jefferson

How many flies need to be buzzing a dead horse before you guys stop beating it? -

Beautiful work there daddy

-

Those are awesome indeed!