Teac A-6300 R2R For Repair

Comments

-

No, that's not one I've seen in person. But, you can definitely see the family resemblance to your deck. Probably designed by the same team. The transport sections sometimes show up for sale without the electronics for reasonable prices.

-

There is an original owner A-7300 near me on FB Marketplace. Price dropped from $4K to $2,500.

It was a top of the line consumer version similar to the studio version 25-2.

It was a top of the line consumer version similar to the studio version 25-2.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Here is a link to a YouTube video done by Victor Komenko about using the 25-2 with an outboard preamp:

https://www.youtube.com/watch?v=TSKyNhZKj3Q&t=38s

https://www.youtube.com/watch?v=TSKyNhZKj3Q&t=38s -

Nice tape pre!

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Yes, I built one based on the P5 minus the capacitor bank upgrade, super easy chassis to work with. Take out a whole bunch of screws and the entire board with rear panel attached comes out. I think there are 19 or 20 screws holding the circuit board to the steel chassis, very rigid.

-

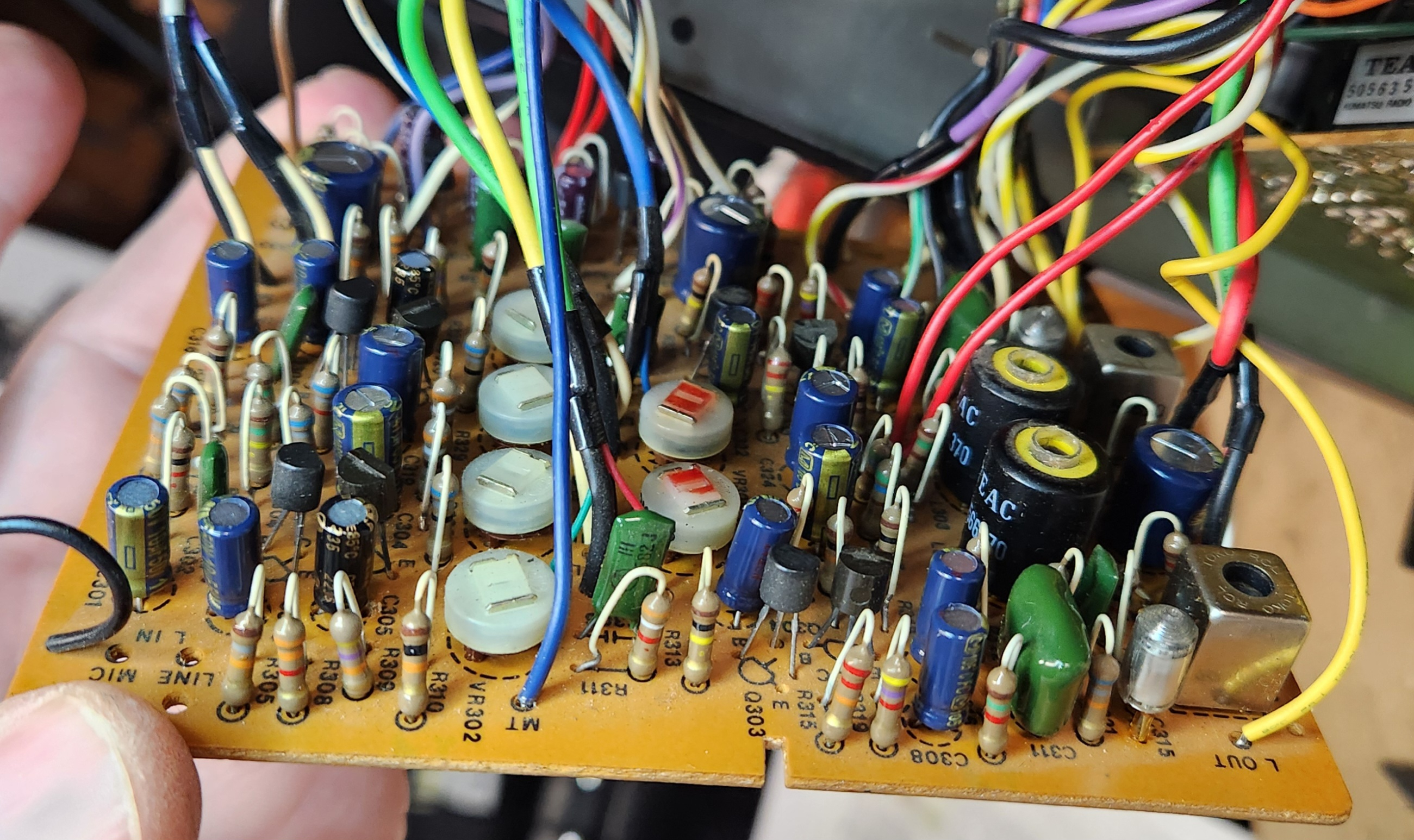

I've been slacking since March. I finally got back on the A-6300. Had some issues calibrating it in March after the recap, just let it sit. Near all the adjusting pots have a plastic shield. Dribbled some DeOxit in them, canned air them out. Much better.

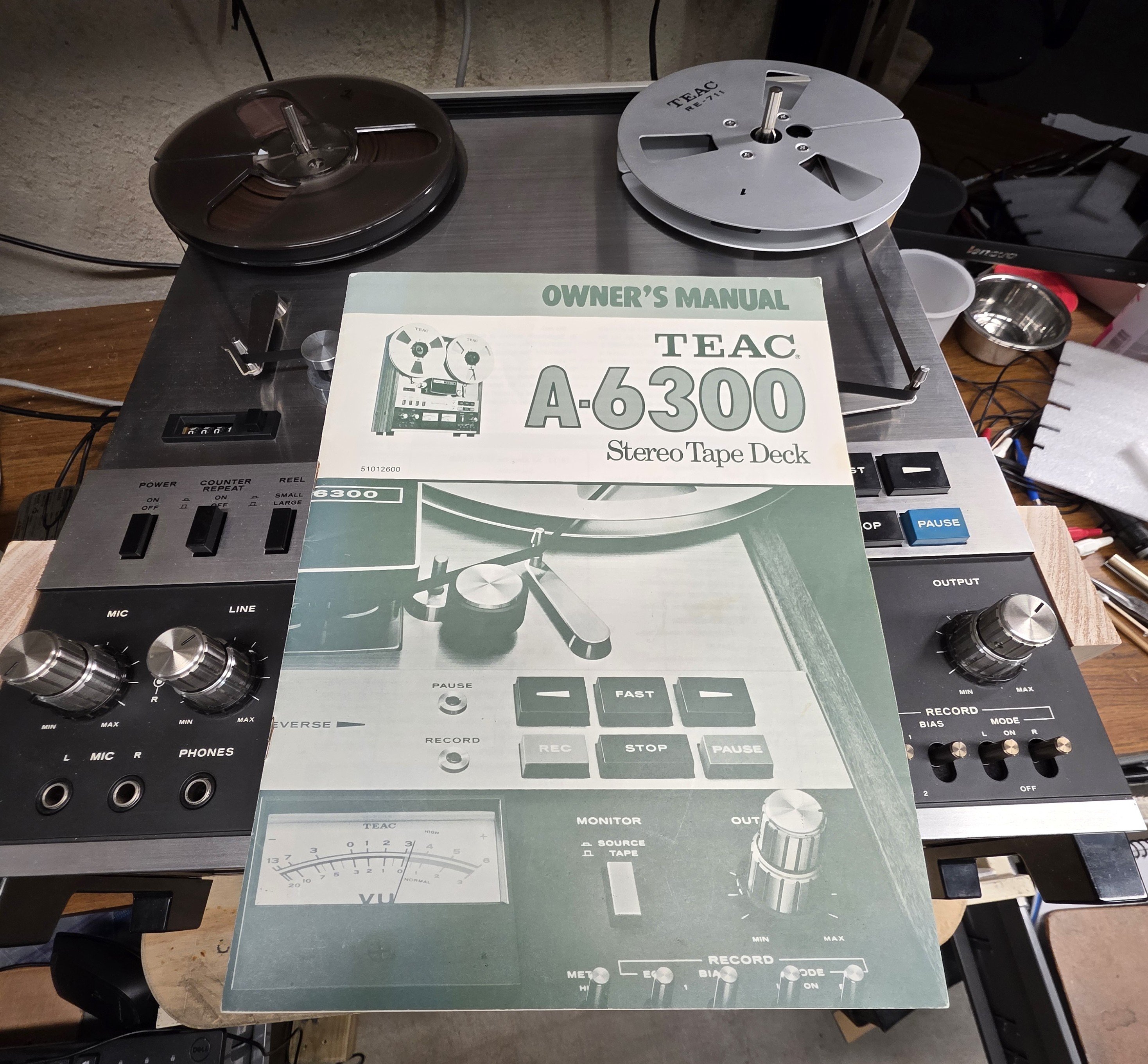

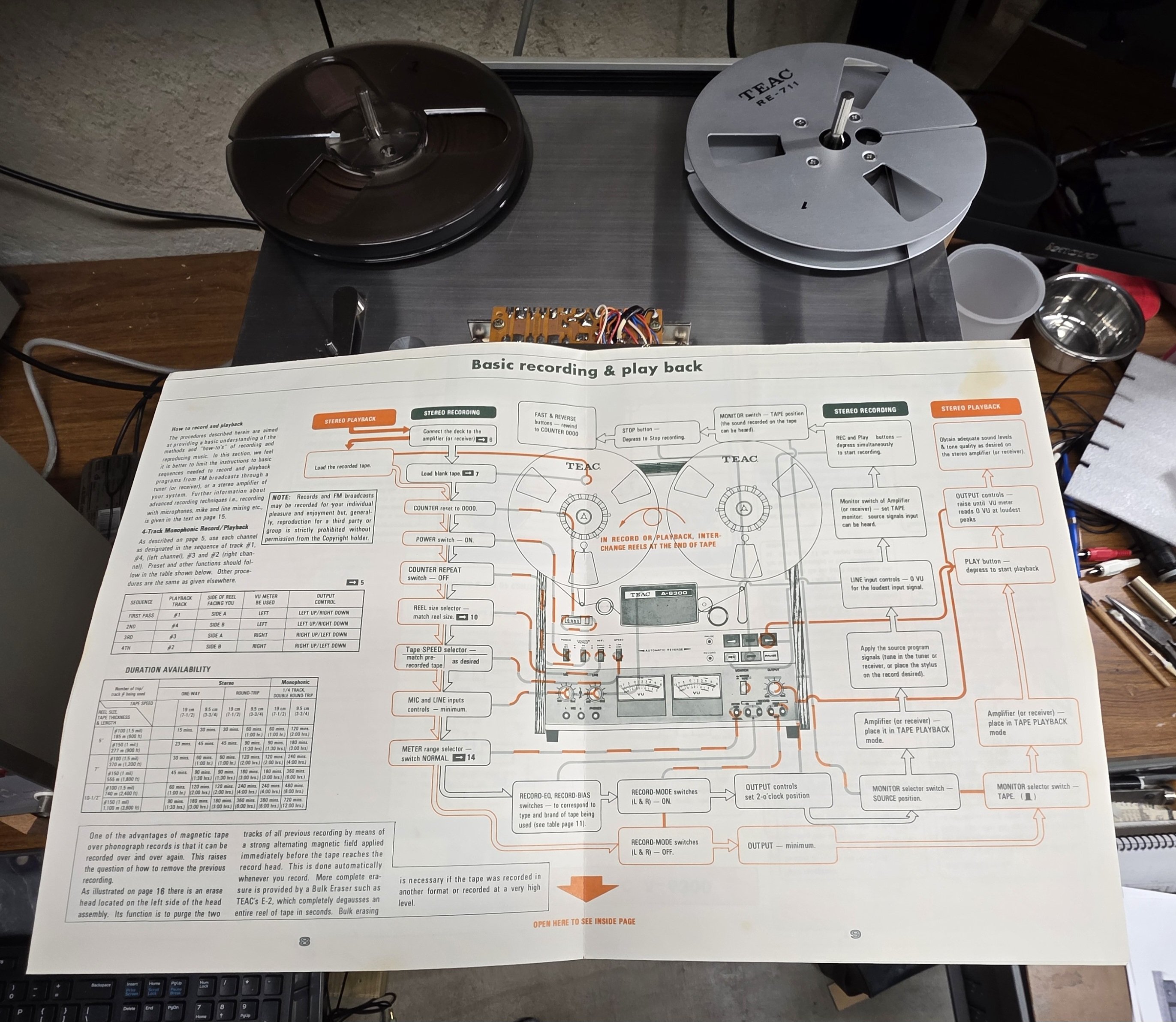

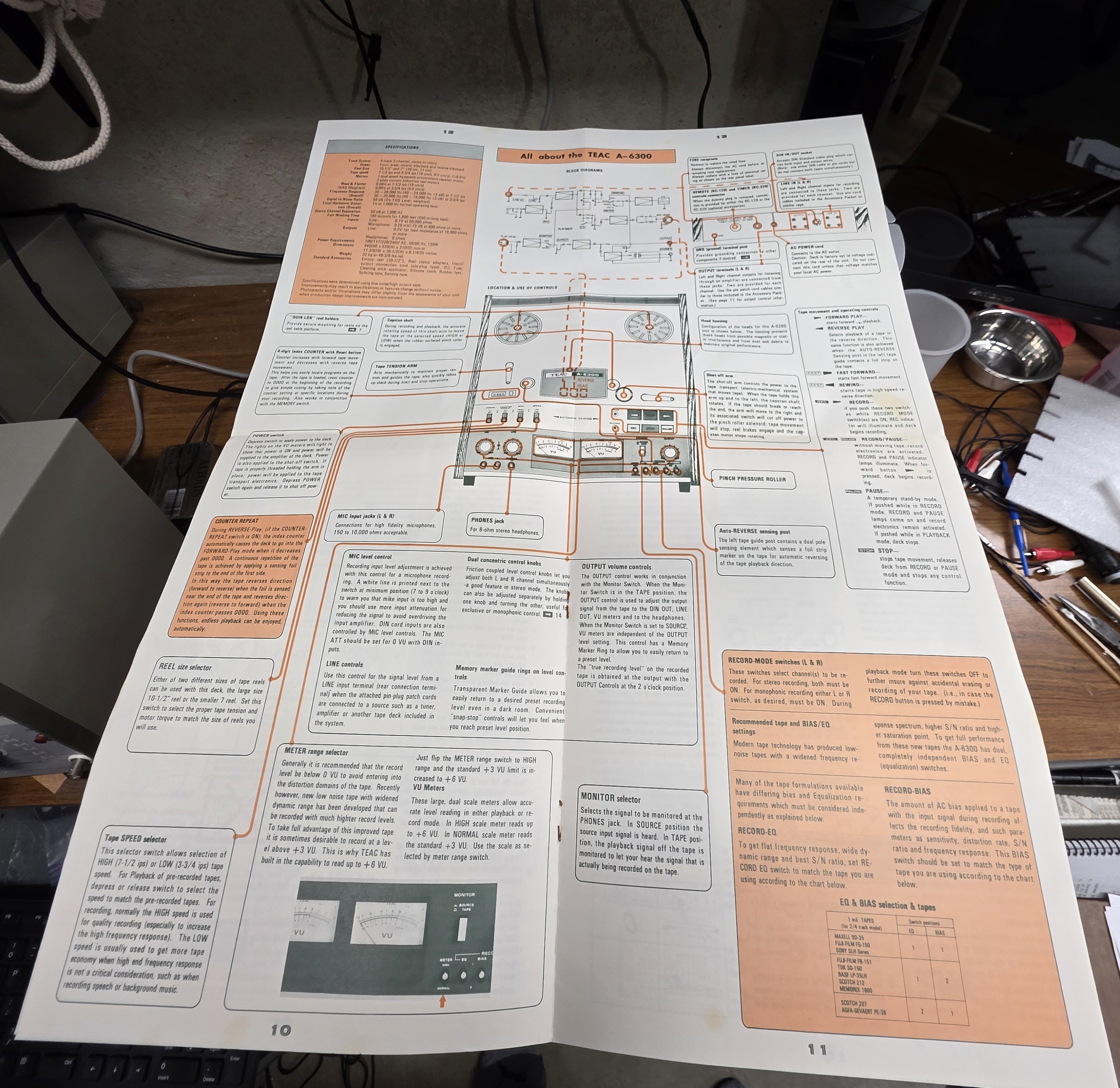

Been watching ebay. Got a nice condition original manual for the A-6300 for $25 shipped.

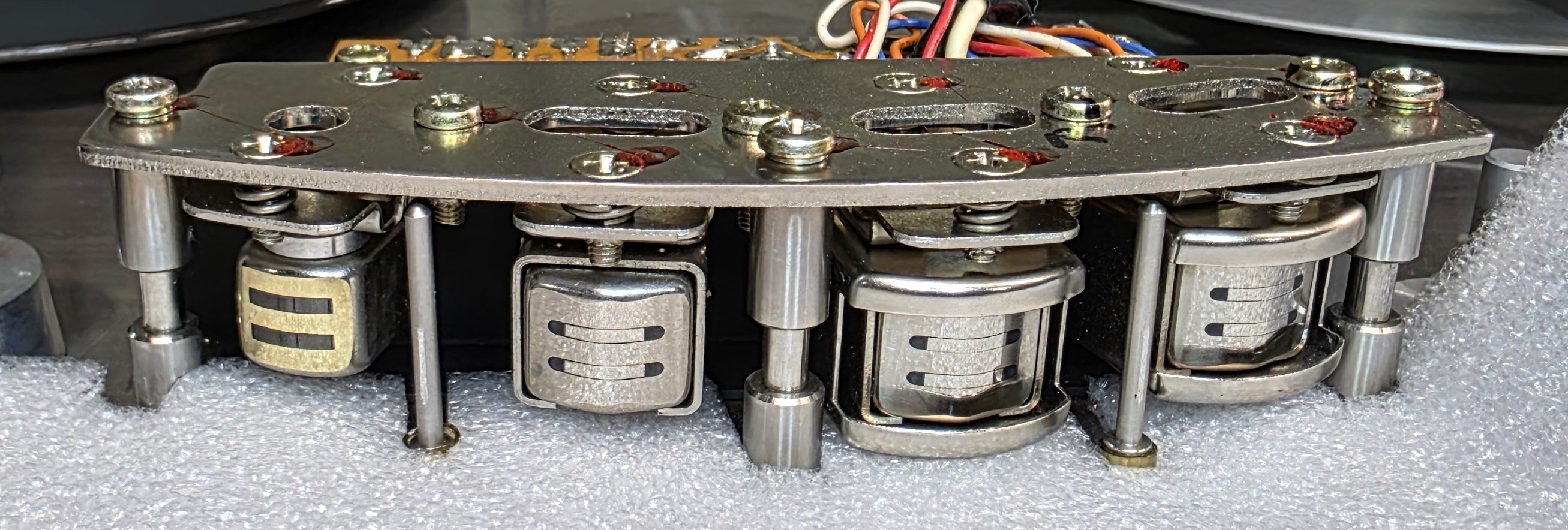

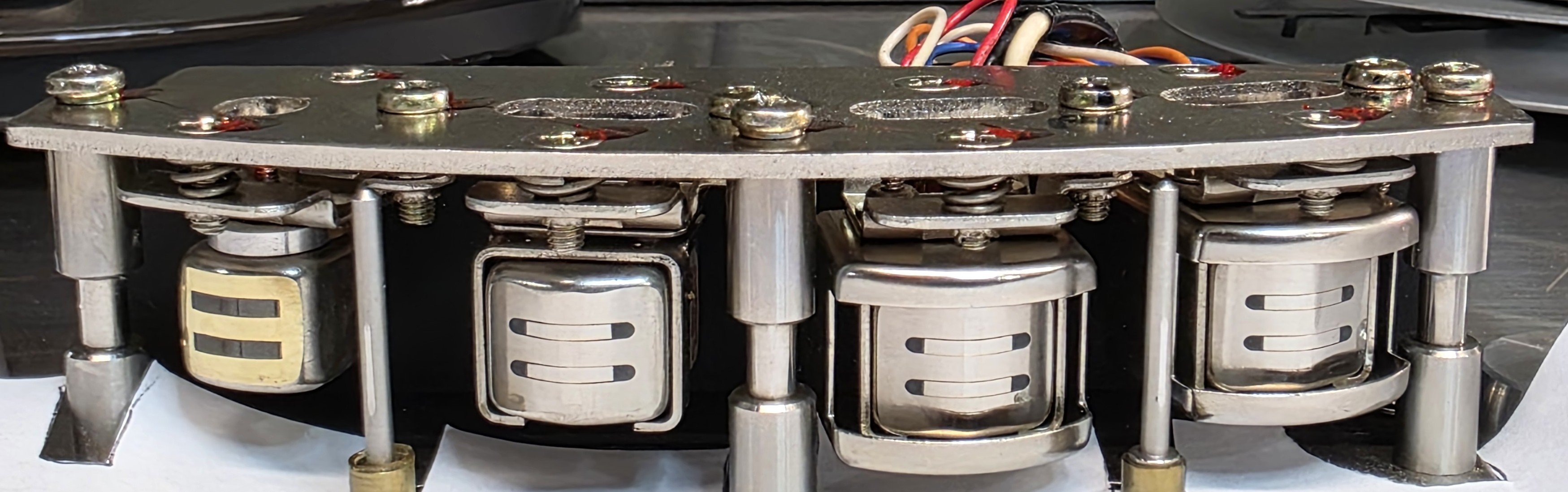

When taking pics of heads, it helps to have a piece of paper under them to reflect light on them. I tried some thin foam packing material. It's a great diffuser but the heads reflect the irregular surface which hides the true condition of the heads. These have very little wear for the age of deck.

Foam reflector under heads.

Paper reflector under heads.

Hopefully almost done..

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Lookin' good Richee! The 6300 is a beautiful piece, built like a tank!Carl

-

Thx Carl! You or Ed need another deck?

I have four here, too many. Pioneer RT-71, Teac 4010SU, A-6300 and X-1000r. Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *

I have four here, too many. Pioneer RT-71, Teac 4010SU, A-6300 and X-1000r. Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

The A series are sooooo easy to troubleshoot/repair compared to the X series, they are fun to work on. So, I snagged another A-6300 at a great price.

It had this sticky grease film on it. Seller said it was from an aunt's estate, no idea. The film laughed at Simple Green. Had to use rubbing alcohol to get it off. Fortunately, it didn't smell like a cigarette. Lots of dust inside.

Heads not worn too bad. Wood sides beat up a little. You can tell they tried to play a tape. Has the typical Teac issue, pinch roller linkage froze due to dried grease. After cleaning, I stuck a good pinch roller and a tape on it, forced the pinch roller linkage up, just press play. It played and sounded pretty good in FWD and REV so ordered a belt.

First two pics from seller ad.

A little better... Still needs some work. Polish the stainless. Clean and lube, DeOxit switches, pots, calibrate, etc....

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

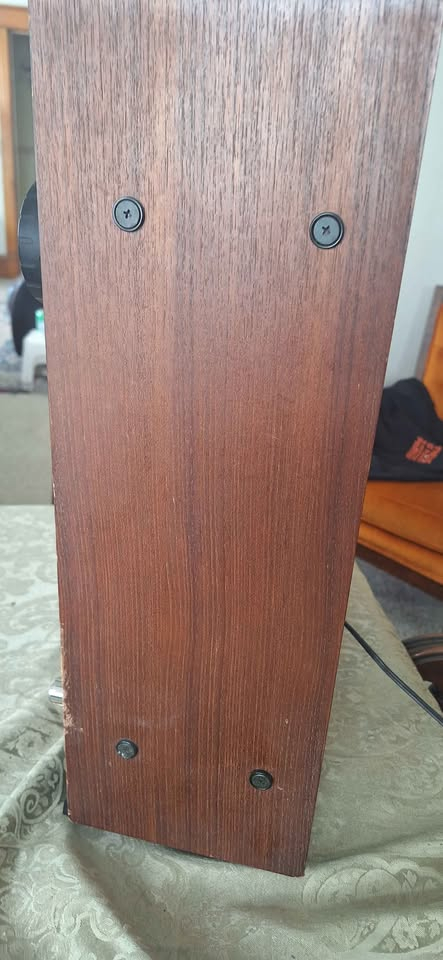

When the front edges of the veneered wood sides are beat up worse than the rear, and you don't have Jesse (F1nut) woodworking skills, you repair best you can, drill new dowel holes and flip them 180.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Just like a Futon!"....not everything that can be counted counts, and not everything that counts can be counted." William Bruce Cameron, Informal Sociology: A Casual Introduction to Sociological Thinking (1963)

-

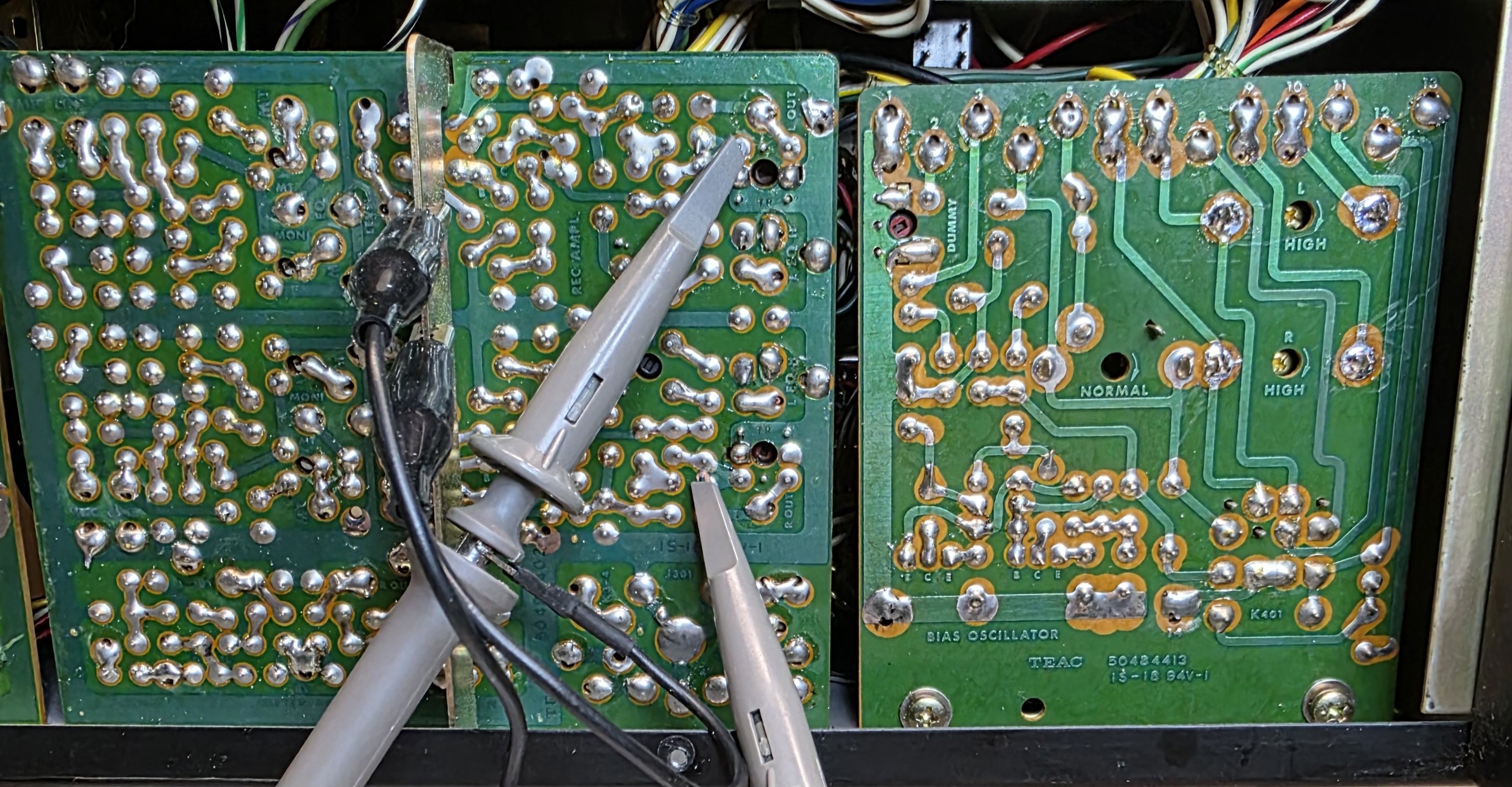

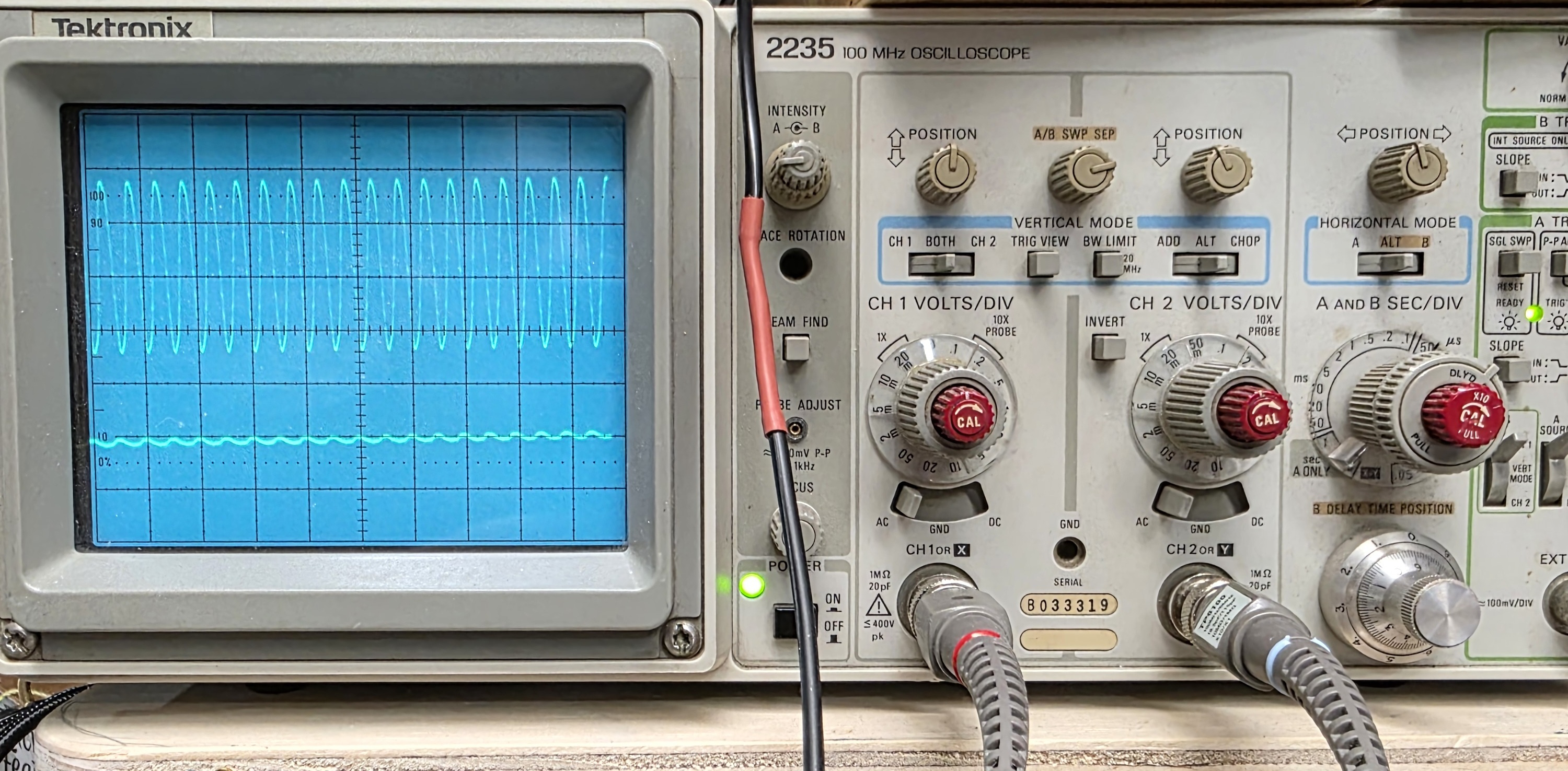

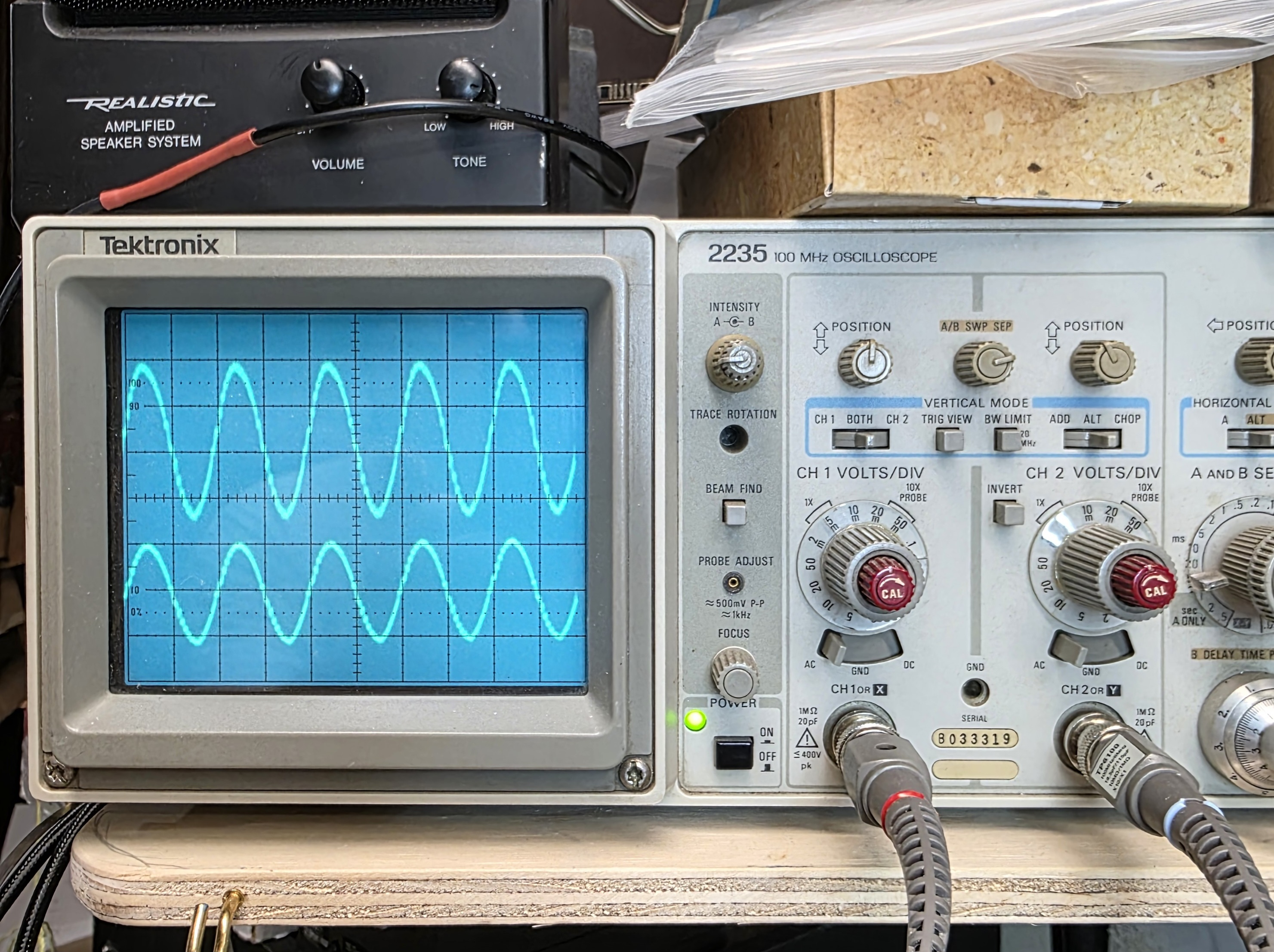

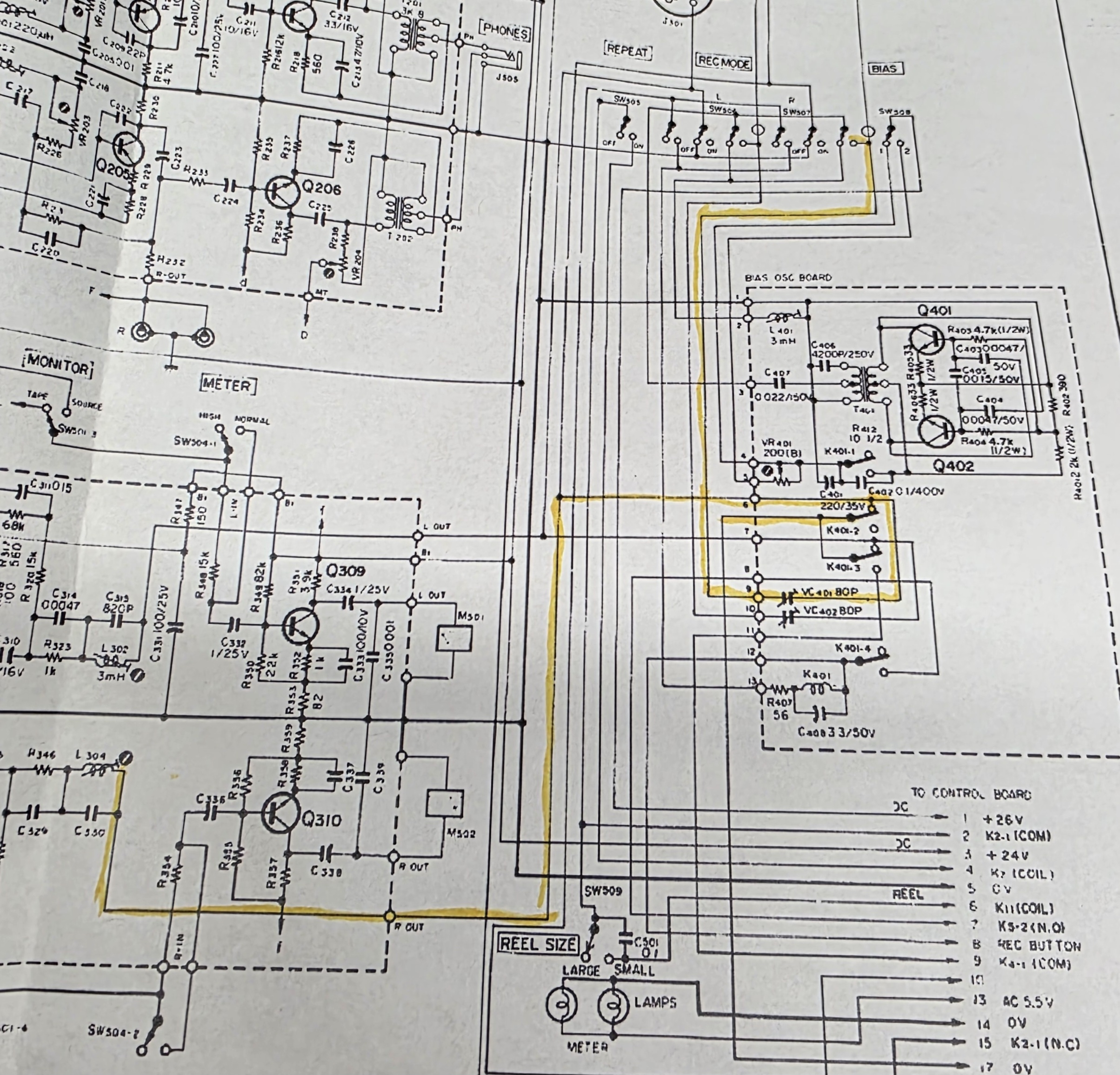

Output and minimum input levels all calibrated well on A-6300 deck two. But, trouble in paradise. Bias trap adjustment, connect scope to test points, press REC and PAUSE, adjust to minimum. I don't expect exact readings between channels, but they should be much closer. Scope channels set to same division.

Even though something isn't quite right, I go to next step, adjust bias. (The bias oscillator spec on this deck is 100kHz +-5%. You need bias to be able to erase/record on the tape).

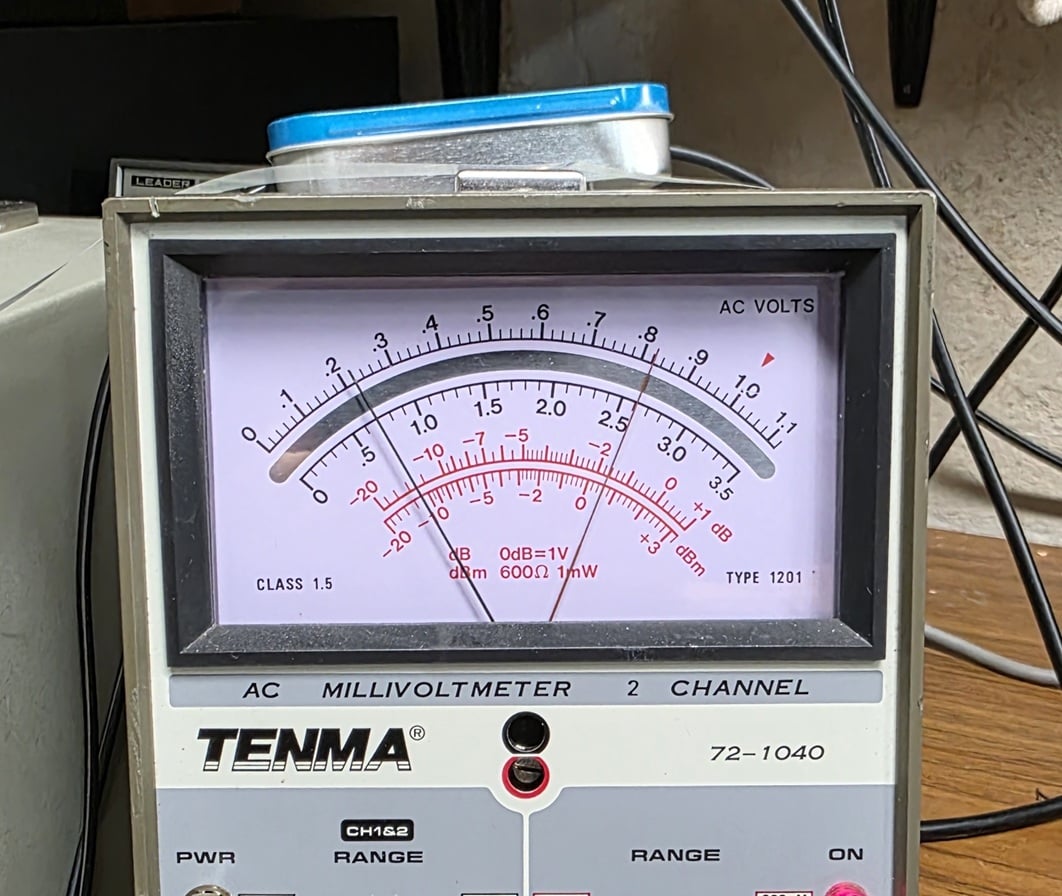

7kHz signal at -18dB. I can't get the range on the R channel. The SM tells you adjust for peak with trim pots VC401/402, then decrease by 3dB. I can't get much of a peak on R channel. (Teac used the overbias method, but I adjust bias by alternating between 1K and 10k signals but for now something isn't right). OH, I'm really enjoying the two channel dB meter!

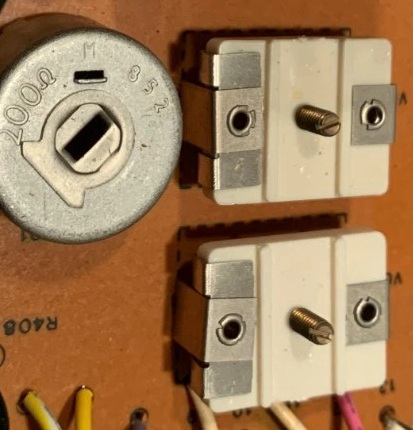

One of the trim capacitors doesn't feel right and gives erratic adjustment. I remove VC401/402 trim caps and test. One is 10-76 pf, the other is more fixed, tops out at 46pf (spec is 80pf).

A piece of clear mica falls out of the faulty one. Now I get a better range, but it still tops out at 46pf. I ordered a couple. For now, I reinstall but swap channels.

Now I get this adjusting bias traps. Scope channels set to same division. It's not uncommon for them to be slightly different. Much better! My bias range is much better too but still need to replace the trim pot. Set this on the side until parts get here.

Bias oscillator board VC-401/402 tied into L302/304 bias trap so guessing the broken mica in the trim capacitor was the issue.

Post edited by SCompRacer onSalk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Well duh, mount holes are not centered in sides, so no flip 180.

However I got some nice Walnut from Aaron's dads tree farm.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

On deck pics. First, original side panels repaired, dark Mocha stain to cover the sins and clear satin poly top coat. An untouched OEM side panel at left. My early serial 6300 side panels had a counterbore as they used a shouldered mount washer while the later serial had flat mounting washers.

New Walnut side, Watco Danish oil with satin poly.

The right side Walnut panel.

Left, late side panel mount hardware (17xxx) right, early (11xxx).

I had three Walnut panels to choose from. This one had some dark areas and didn't match first two Walnut side panels, even though you can't see both sides at same time.

Post edited by SCompRacer onSalk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Cherry sides, first coat Tung oil.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

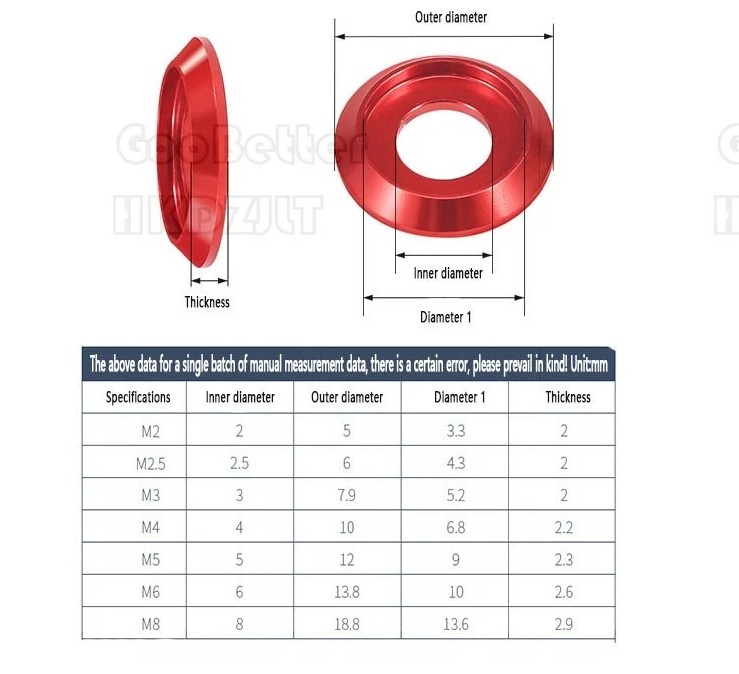

The new hardwood sides get a finishing touch. I obtained some aluminum anodized shouldered washers and M4 Phillips head Stainless screws with black finish. (Allen and Torx head are also available). They replace the OEM flat head screws with plastic shouldered washers. Sometimes the OEM screws are in sad shape from poor storage or stripped from using Phillips instead of JIS drivers.

You can get the shouldered aluminum washers in various sizes at ebay or Amazon. They offer different colors too. I went with black on black. I liked the contoured head of these screws better than new flat ones. I guess you could call them a flattened pan head. The seller only had these style M4 screws 60mm long so I cut them down to the 22mm length needed.

I had to use M5 washers as the M4 screw head (8.7mm) is too large for the M4 recess (6.8mm). (They are sized by hole in washer). The recess in the M5 is ~9mm while the head of the M4 screw is ~8.8mm so it's a snug fit. The OD of M5 aluminum washer is the same diameter of the OEM screw head.

I liked the shape and gloss to match washer. One could go with bright stainless screws too.

Other option, flat head with a flatter finish.

A taller Fisheye style washer is available.

Two coats Tung oil.

OEM left.

Post edited by SCompRacer onSalk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

SCompRacer wrote: »Cherry sides, first coat Tung oil.

By far my favorite wood, for furniture and smoking. -

By far my favorite wood, for furniture and smoking.

Aaron has me thinking about a Cherry (or ????) cabinet for the X-1000r to replace the OEM fake vinyl wood wrap cabinet. The capability regarding tools is there at his brothers shop for the perfect sized square cabinet. The difficulty is all the thin shim pieces inside. Lots of (cue Hervé, The plane! The plane!) planing work.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

DO IT!!!

-

I say do it also! The X-1000 cabs are really cheaply made.

Carl -

After some interruptions and lack of interest, it's time to get back on the second A-6300 deck so I can sell it. I had playback frequency response calibrated very well on both decks. Record on both decks needs some tweaks varying record EQ cap values, so the record frequency response is as tight as the playback response. Older tape got a frequency boost in the 7-10kHz range that modern tape doesn't require. More on this process later.

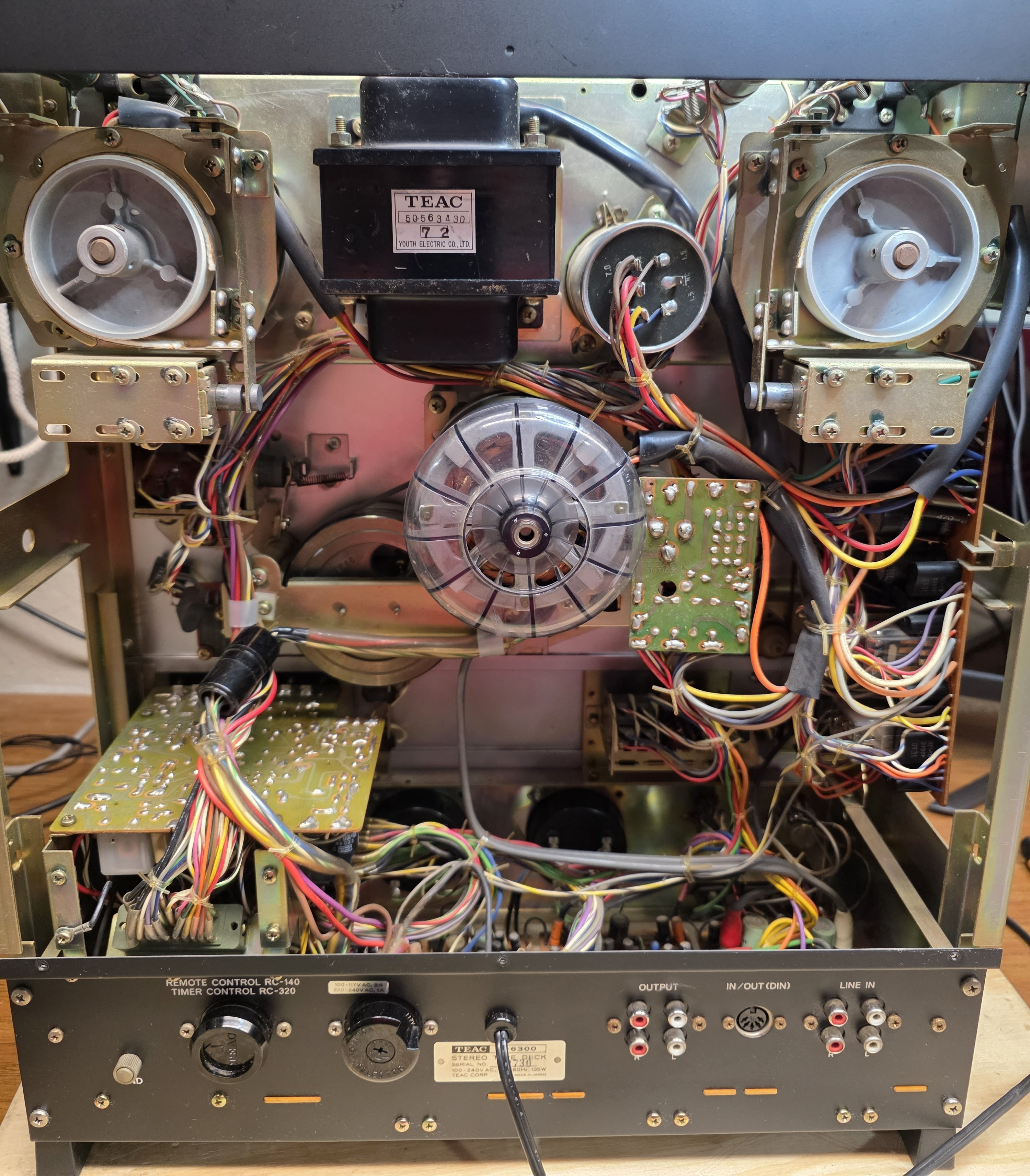

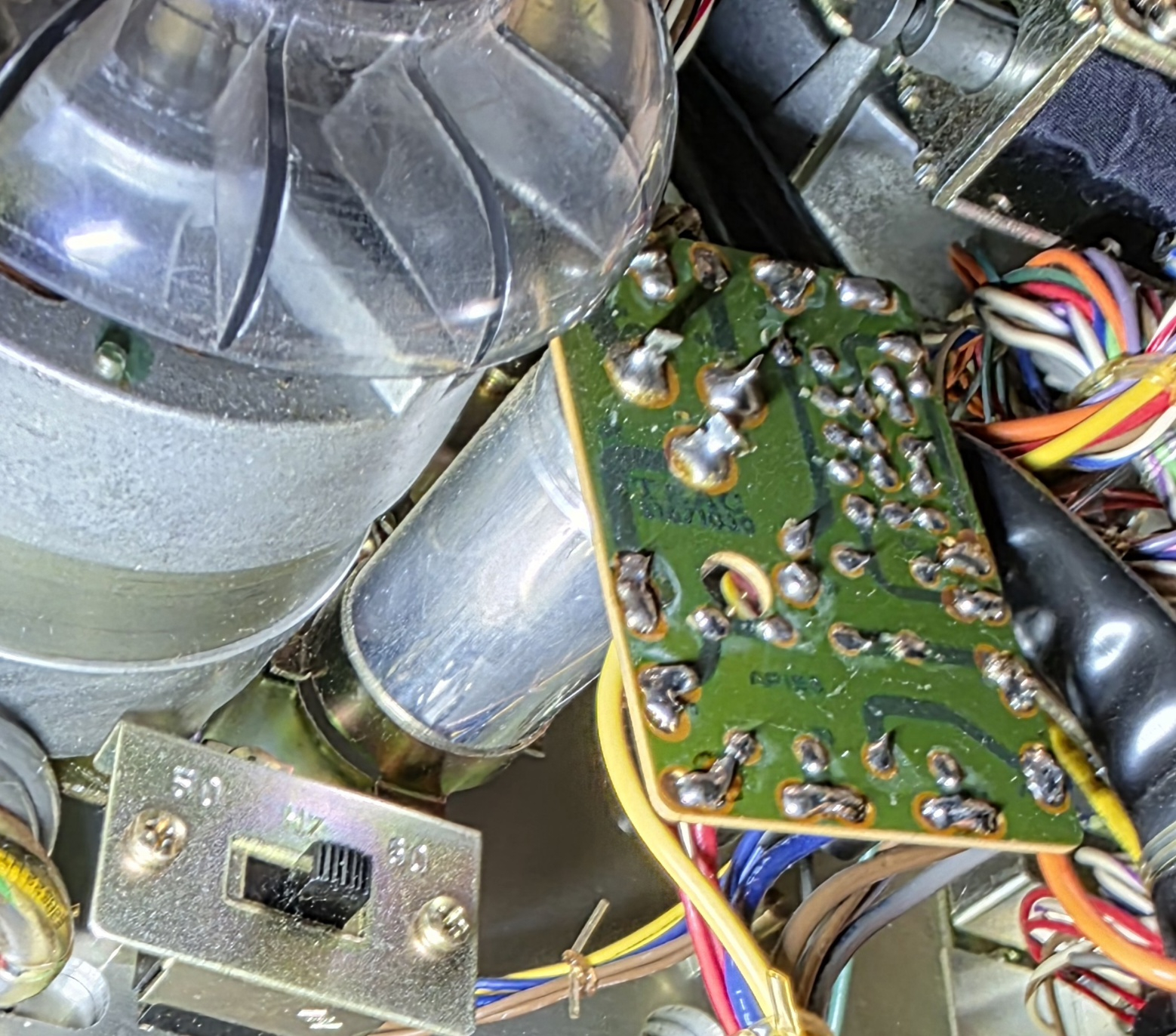

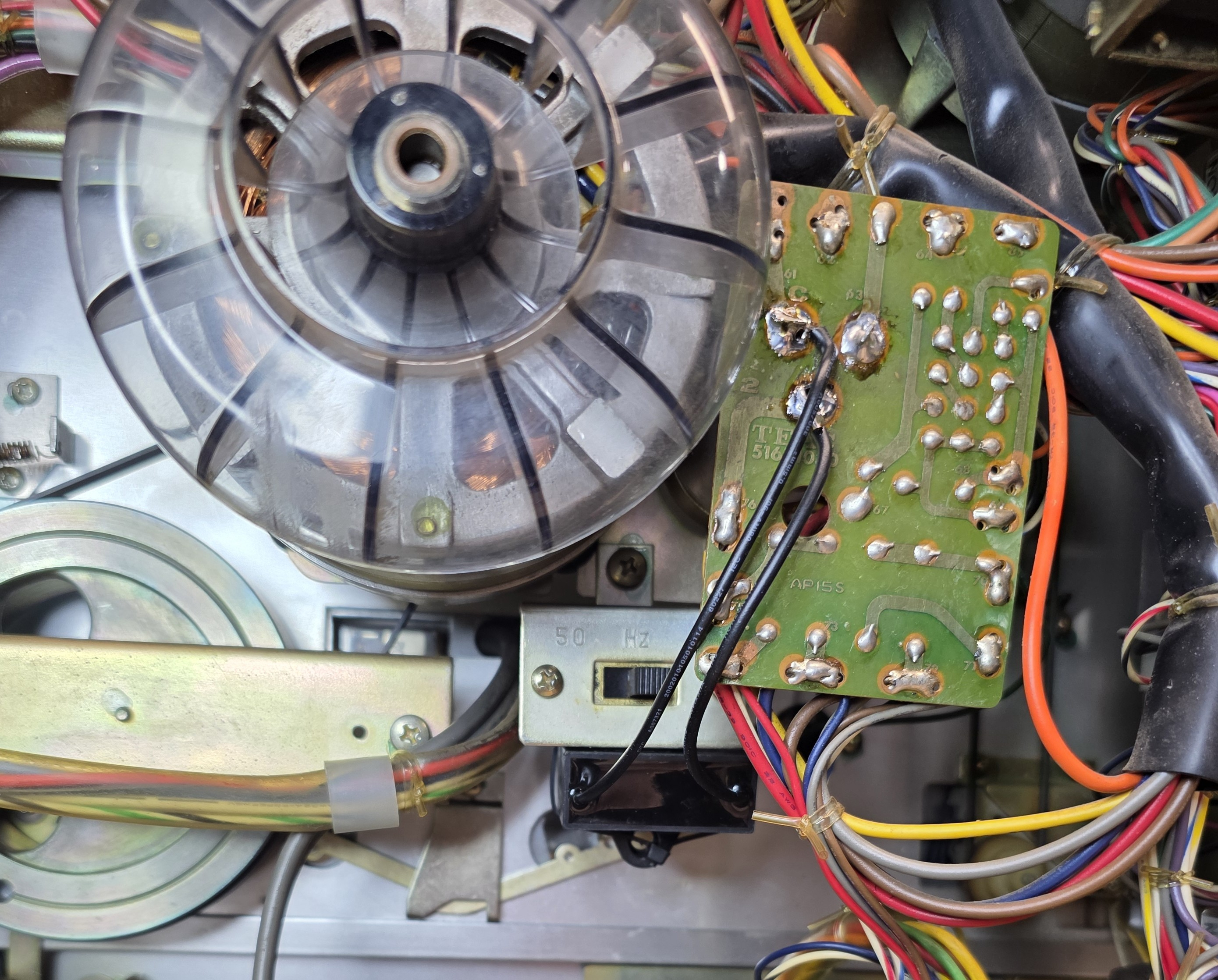

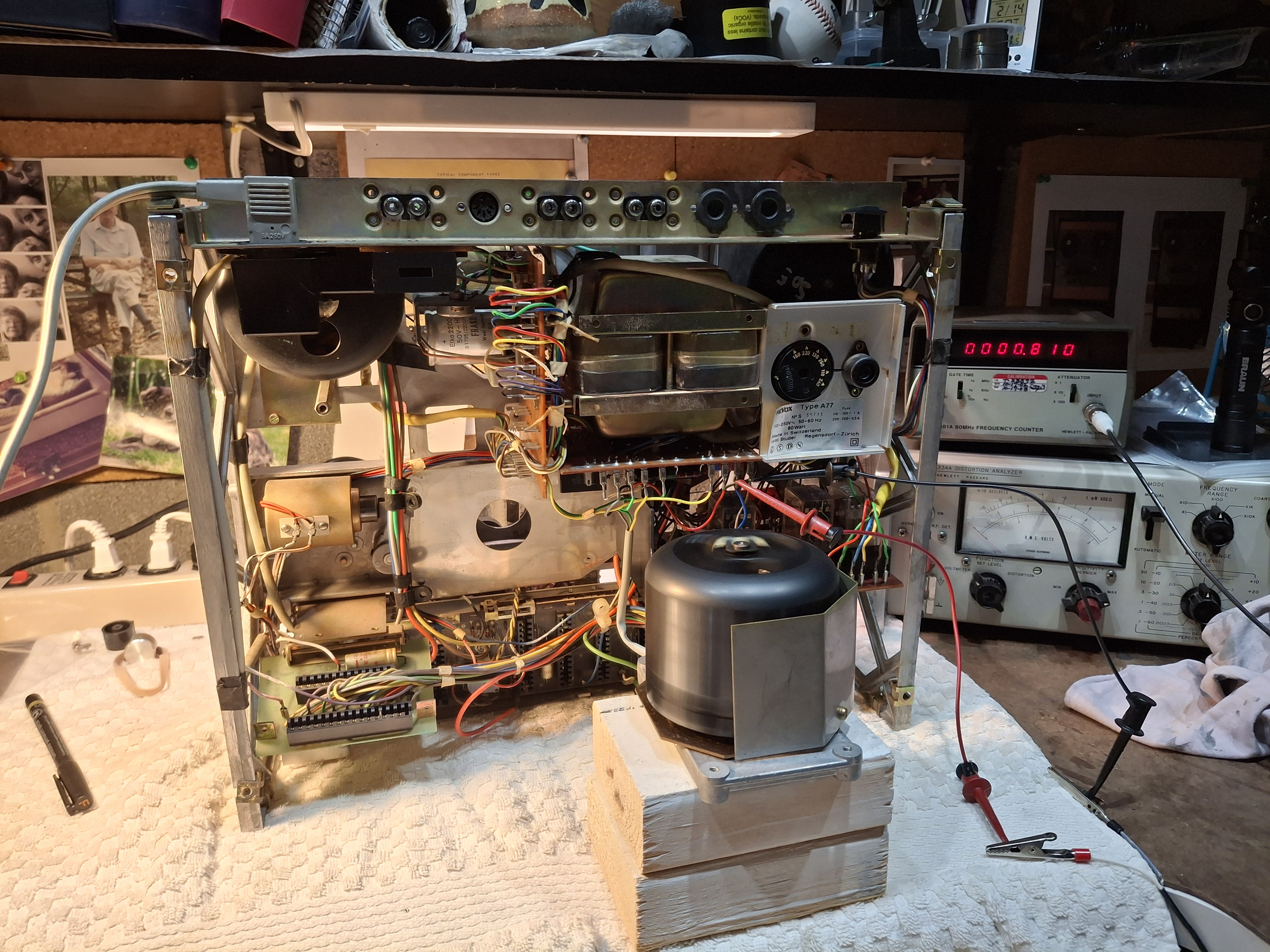

When I first attempted the record EQ mods, I ran into capstan motor speed issues on the second deck. Motor run caps can fail or cause speed issues like the ones in ceiling fans.

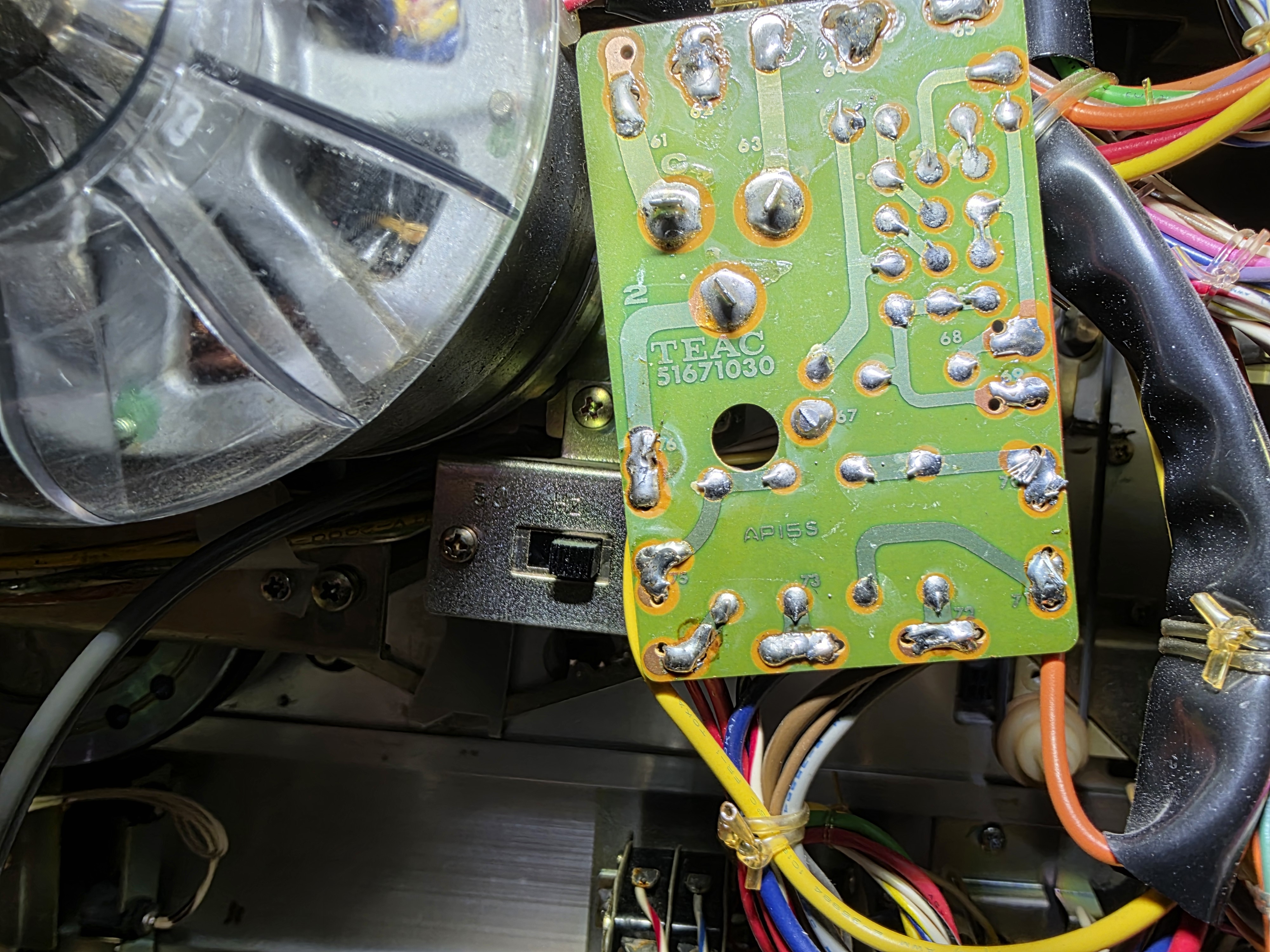

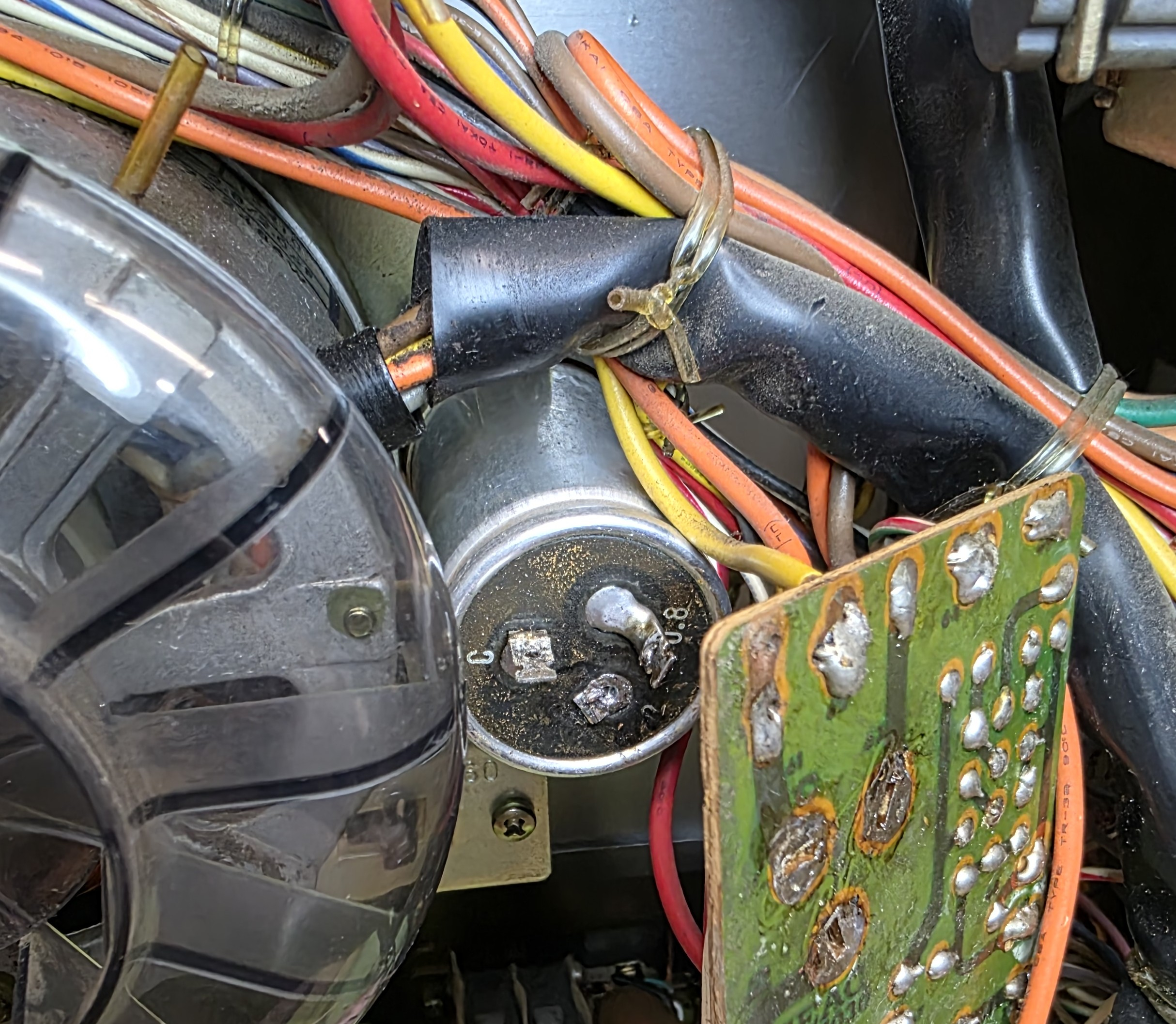

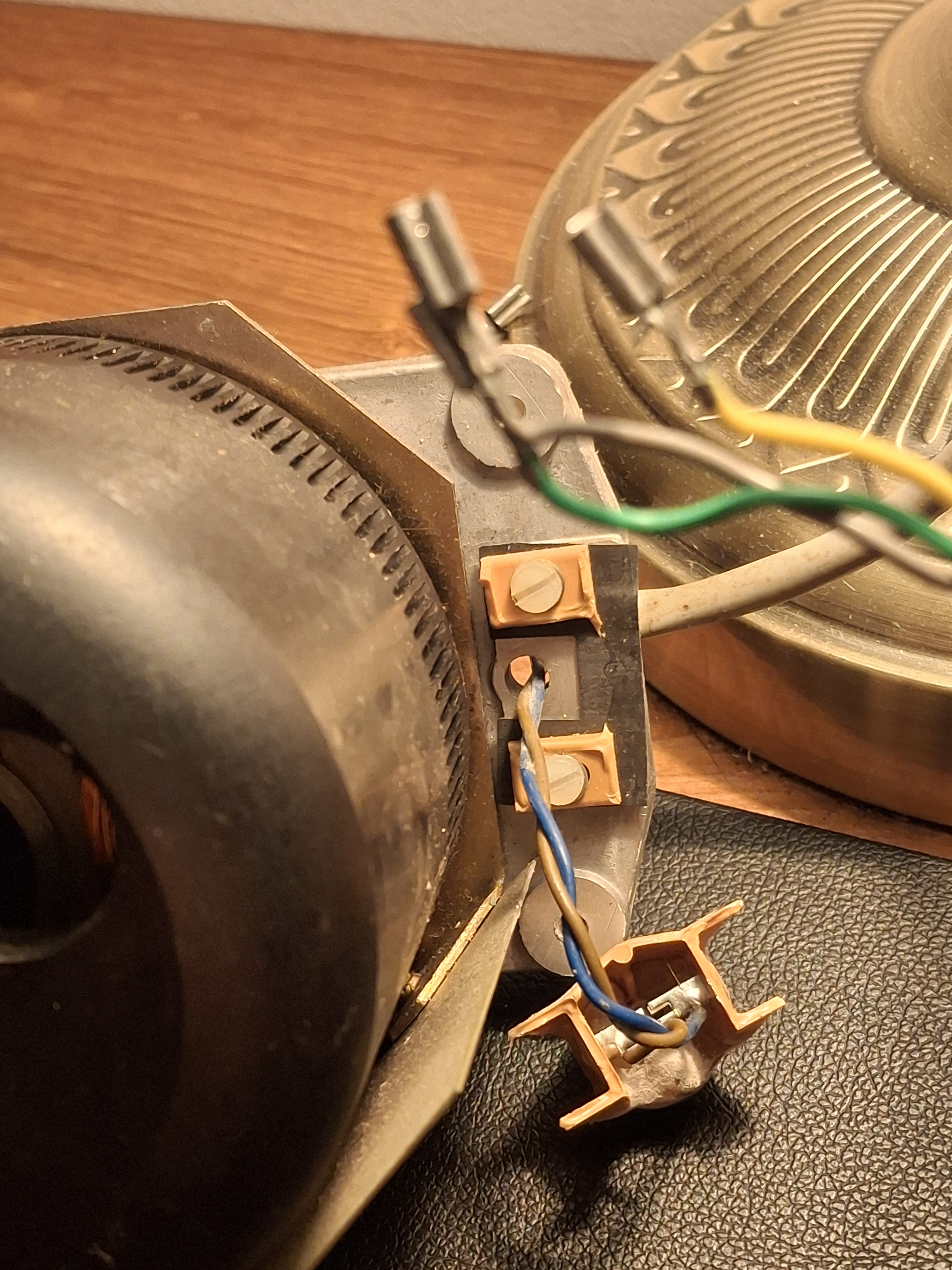

Teac mounted the base of capstan motor run capacitors to the inside of deck. They soldered a motor run PCB to the top terminals. Remove the can, now you have to secure the PCB to prevent it from flopping around and shorting out. Motor run caps for multi voltage decks will have two values, one for 60Hz and a second value to boost capacitance for 50Hz operation. (The other thing, you move the capstan motor belt to a larger 50Hz pulley).

The 6300 capstan motor capacitor has two values in it. A 2uf for 60Hz operation and a .8uf value added to the 2uf by flipping a switch for 2.8uf 50Hz operation. One way is to desolder the terminals from PCB, cut the 60Hz tab off and resolder the common and .8uf 50Hz terminals back on the PCB.

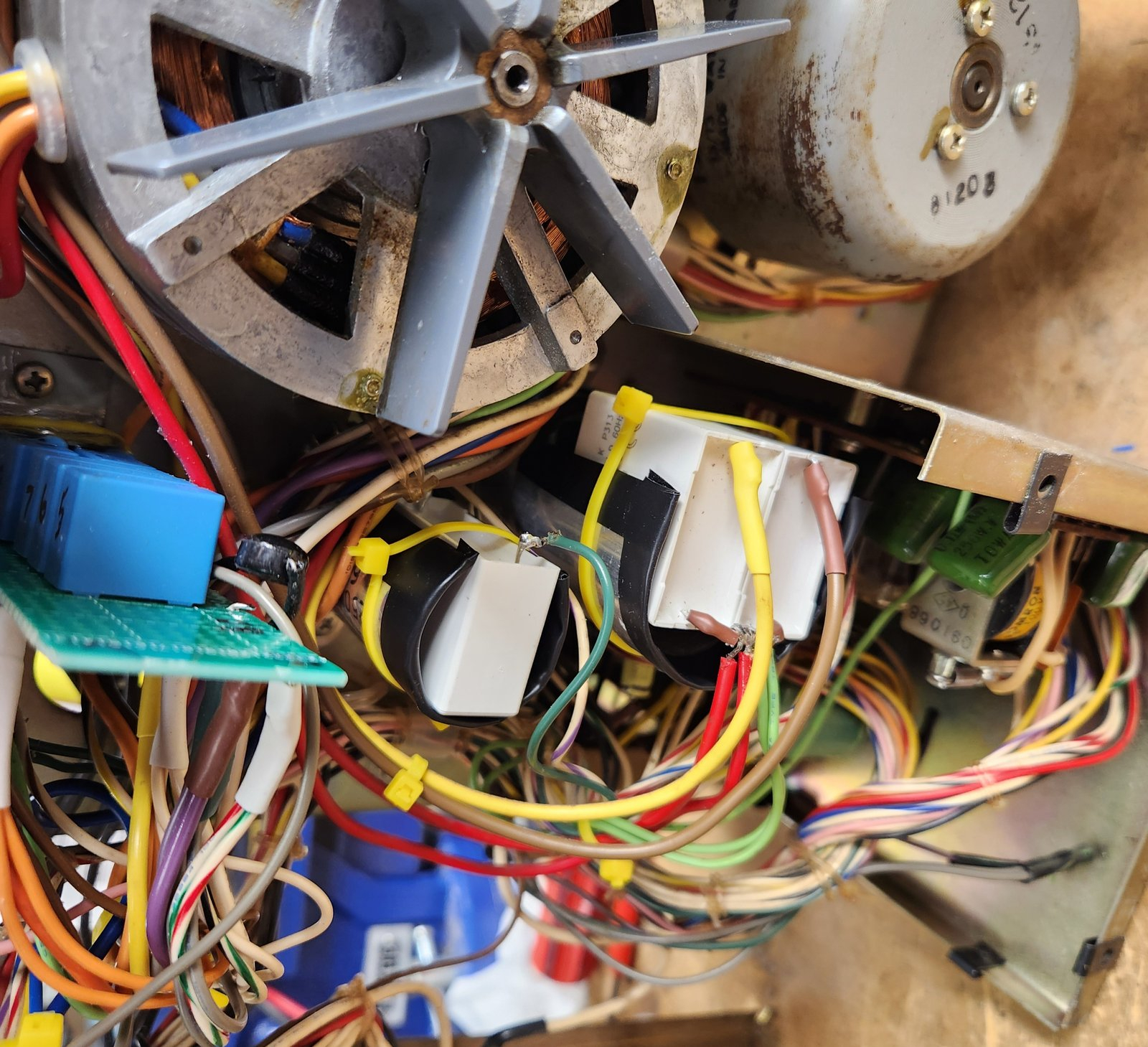

Then solder one wire of the ceiling fan motor run cap to the C or common terminal and the other wire to the 2uf trace. I zip tied the motor run cap run to the 50/60Hz switch bracket.

In a previous deck, a Teac A-4010US, I used Icel by Nichicon MAB series motor run capacitors for capstan and reel motors. Mouser and Digikey were out of stock for the value needed. They mentioned minimum order, tariff issues, so I got a ceiling fan motor run instead. The motor run capacitors in that deck were also mounted at the base with wires to terminals (no PCB), so I gutted the cans, covered sharp edges and zip tied the new caps into them. It was a US only deck and while the cans contained 50Hz values, no wires or 50/60Hz switch were installed/connected.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

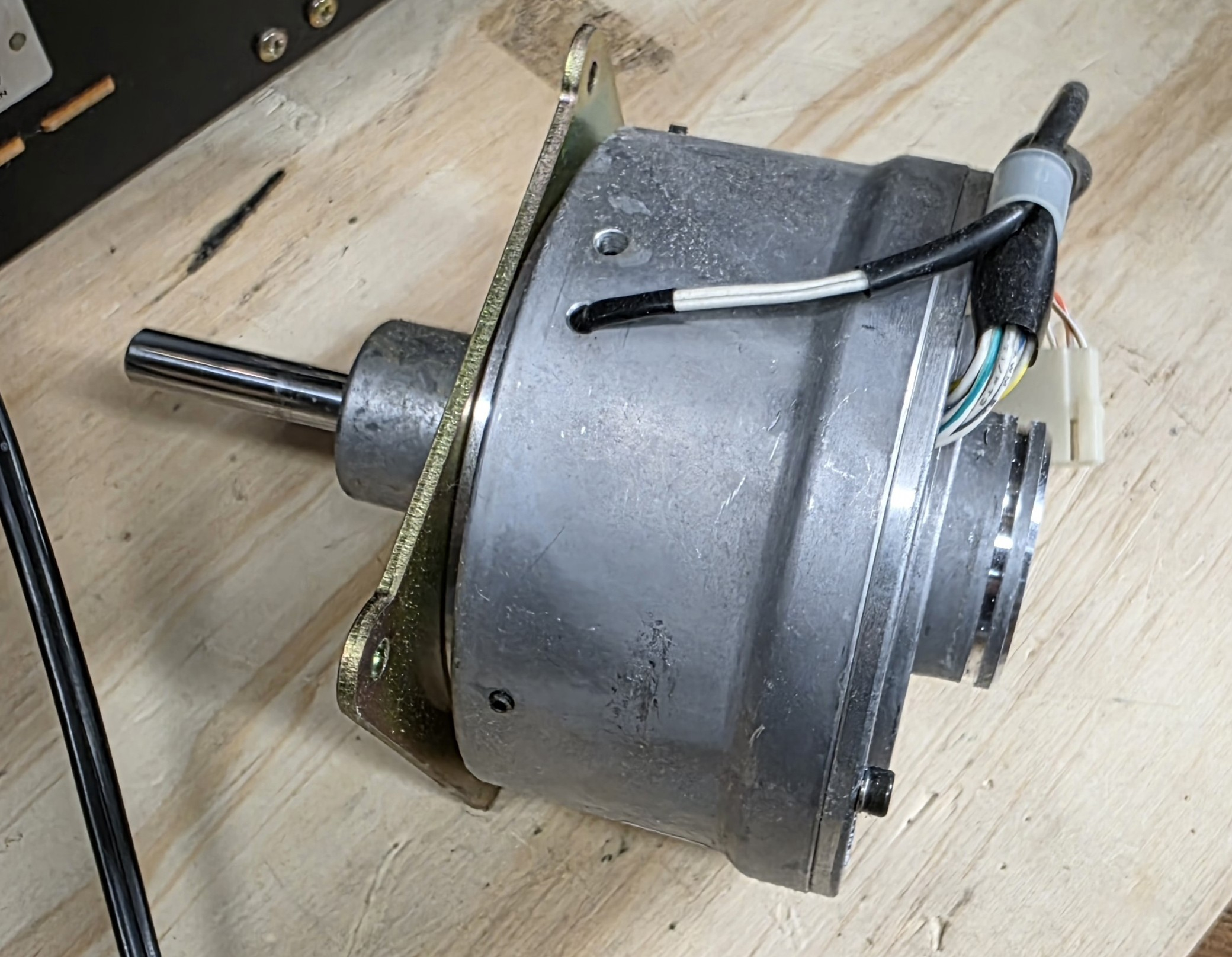

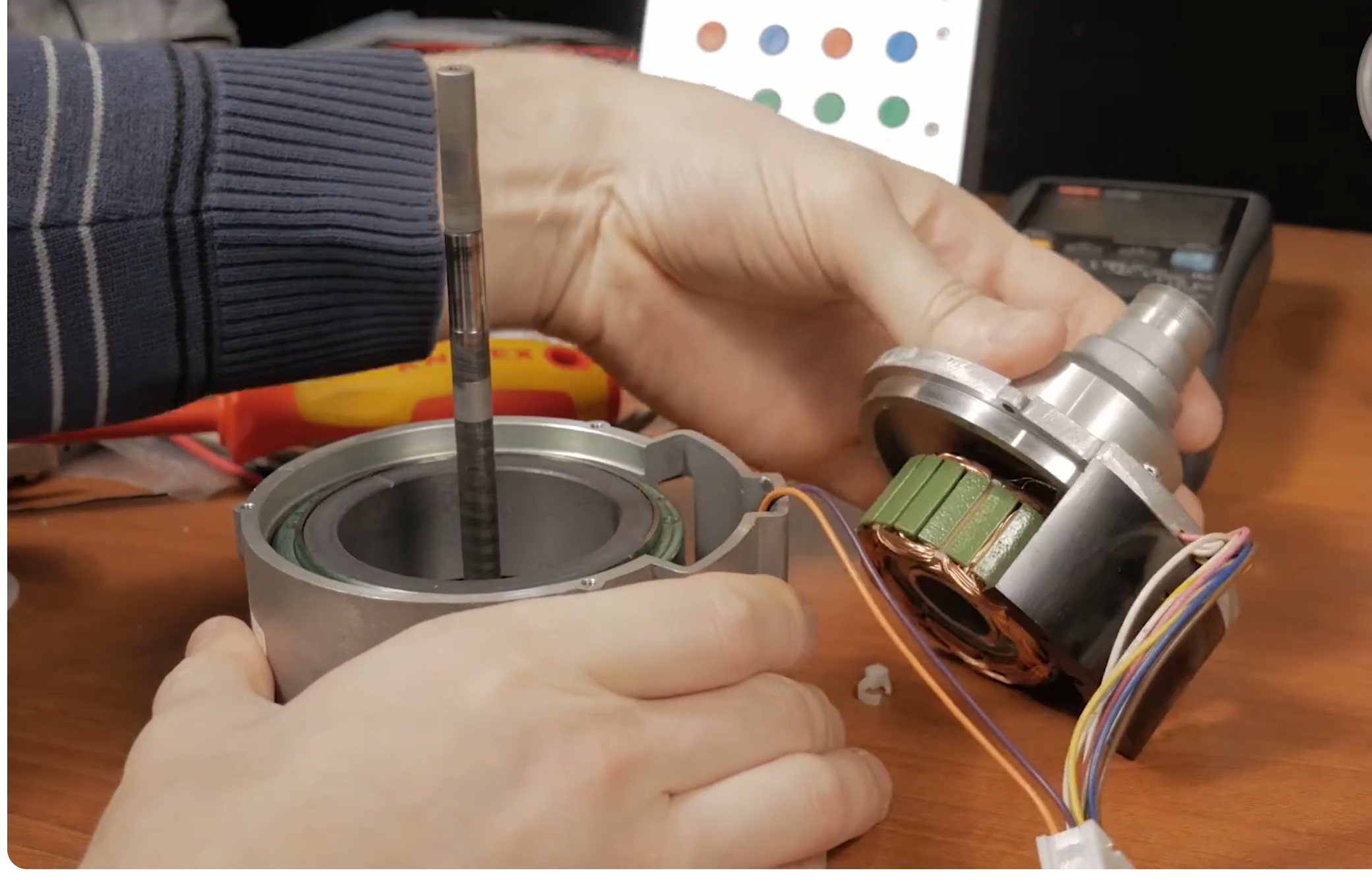

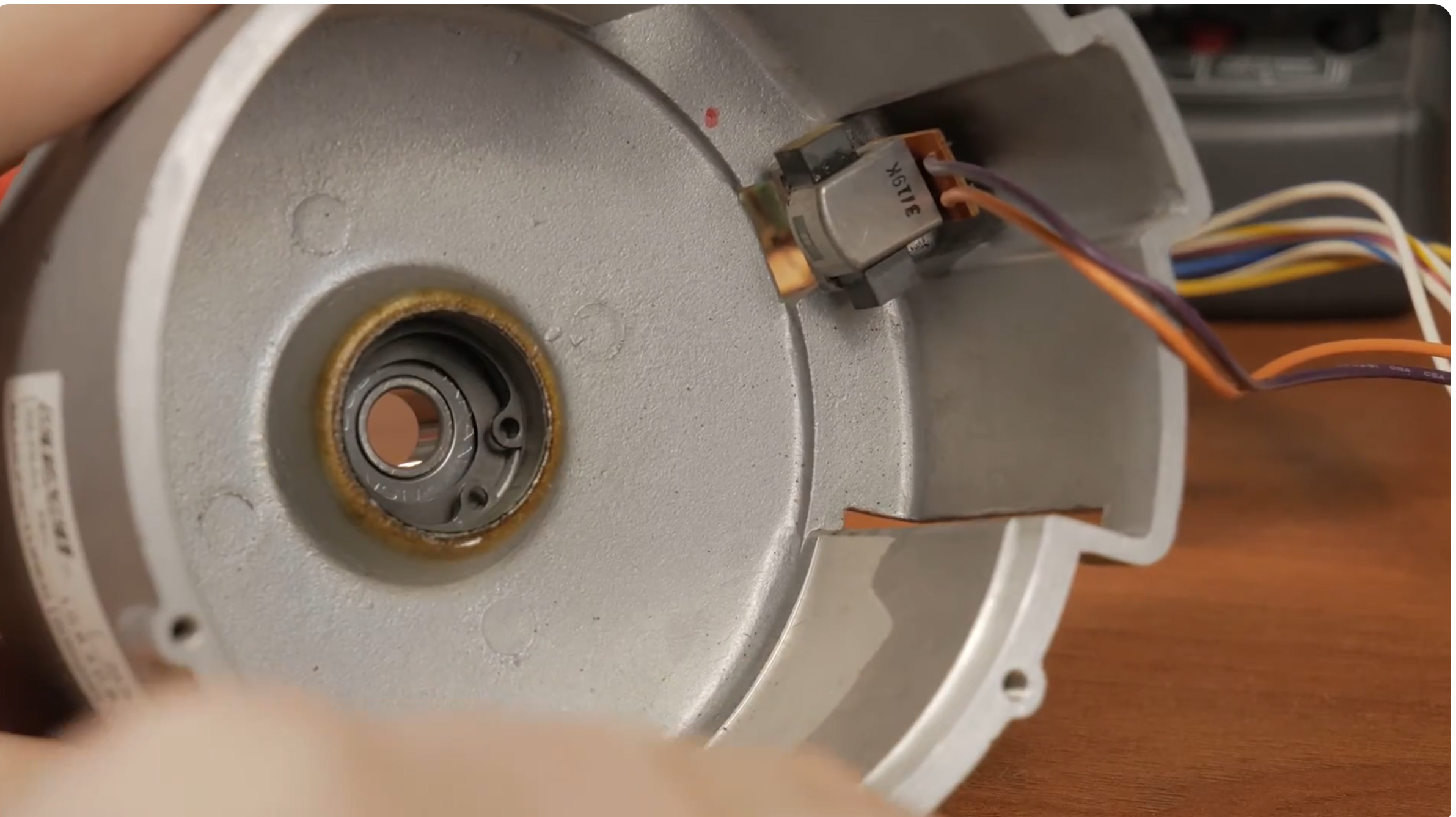

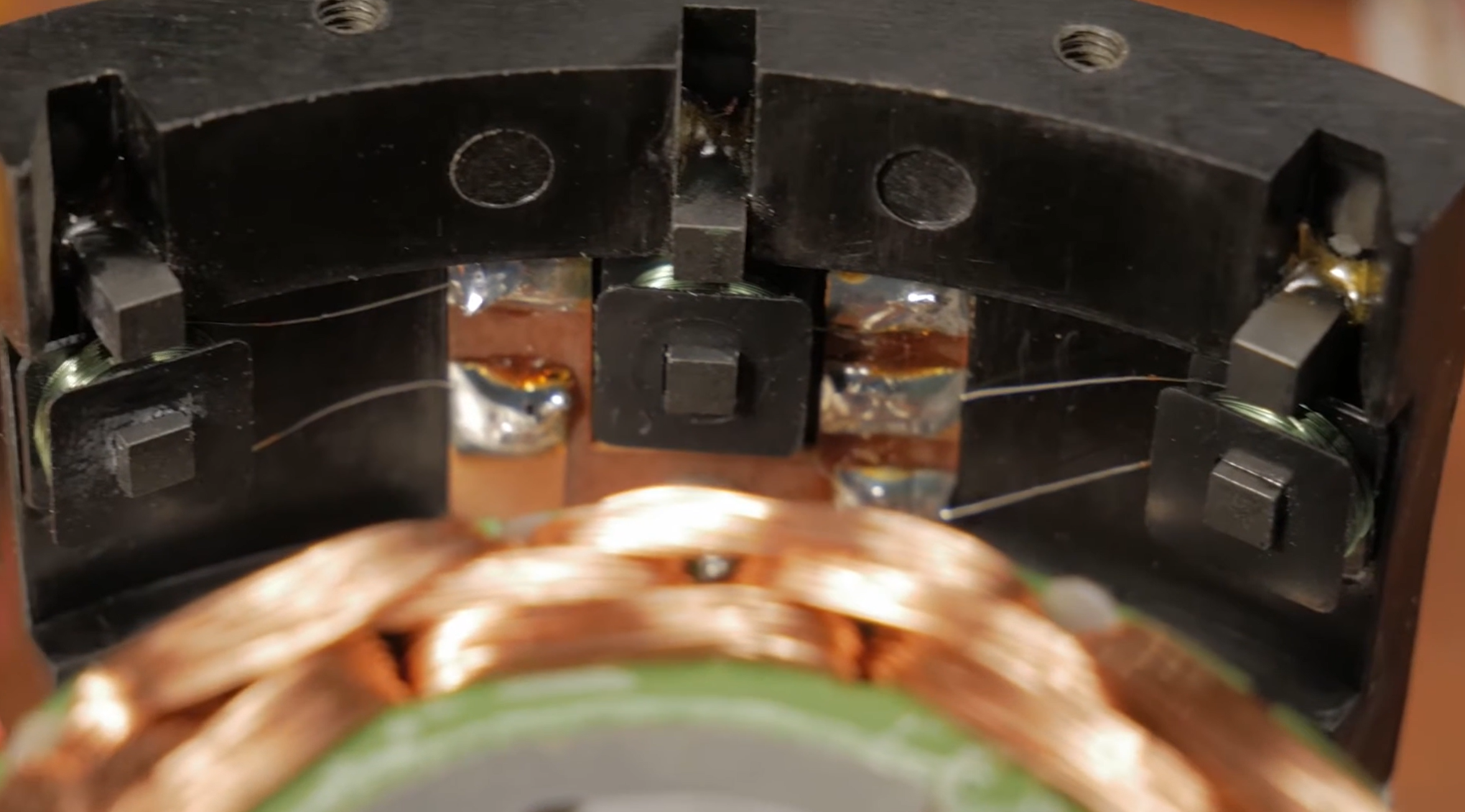

Nice to see your progress on the Teac, Rich. I'm working on a Revox A77 for a customer and it has some speed issues as well. The A77 uses a tachometer placed close to the spinning rotor of the capstan motor. I initially suspected the speed control board and since it is a feedback loop circuit it is difficult to diagnose. I ended up checking every component on the board and replacing some out-of-spec capacitors. But the problem still happened, the capstan motor would rev up going faster and faster. Then I connected a spare motor to the circuit and it worked fine, this indicated the problem was connected with the motor. After pulling the motor I could see a broken tachometer mounting:

-

I used a two part epoxy, Araldite, to repair the tachometer then connect it to the speed control board using a test jig I have and it now worked.

-

Nice save and fix Ken! The Teac A series are not quite that sophisticated.

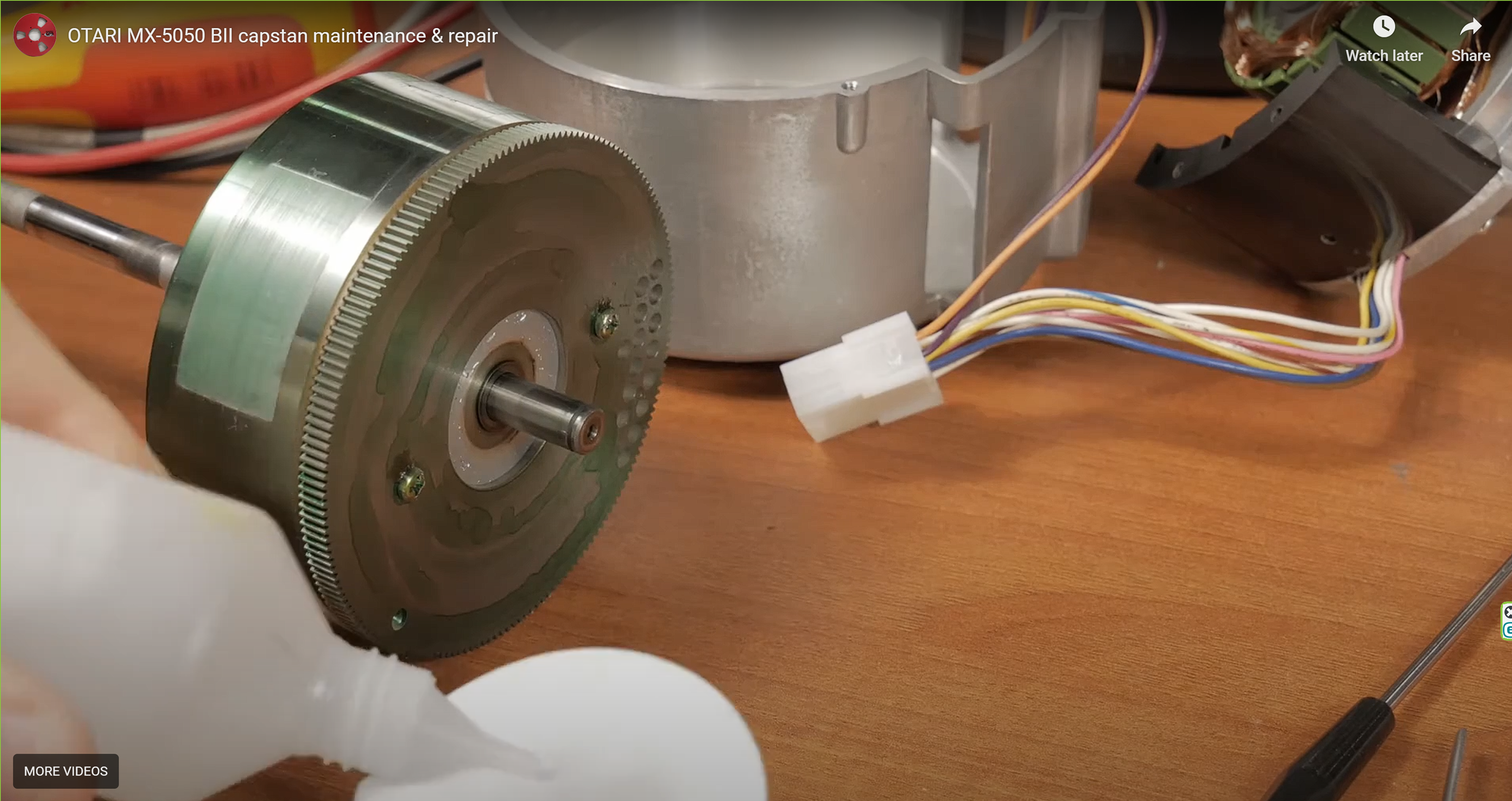

My Otari capstan motor has some rotation sensors and two magnets on the side of a tach head that can loosen/fall off with rough handling while shipping. While searching for Otari MX-5050 BIII-2 info, I found a youtube video by Anthony Scott showing the preventative re-gluing repairs. The video shows a motor for a BII, same motor used in BIII. It's on my to do list.

I found the info/video after removing and reinstalling my capstan motor to access sticky pinch roller arm/tape lifter linkage. The BIII added a harness plug to the motor while the BII wires were soldered to a control board. Anthony added Molex wiring connectors to his BII motor.

https://youtu.be/McqL88f9anI?si=ws4UMZtkpZ7fgjIO

https://youtu.be/McqL88f9anI?si=ws4UMZtkpZ7fgjIO

Post edited by SCompRacer onSalk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *