Going to try circuit board soldering, what tools do I need?

muncybob

Posts: 3,262

in Electronics

I figured I woud ask the experienced people here what quality tools should I be looking for instead of buying and regretting. I have very little experience soldering but will hone my skills on some crap I have laying around before opening up anything valuable.

With that said, what brand/type iron, helping hand, solder or anything you can think of should I consider buying? Utlimatley I would like to replace some of the caps in my preamp. Also never did this before and I am concerned about needing to drain them before working on them? If this is a wise move, how is it done or can I feel safe if they are laying dormant for an extended period of time?

With that said, what brand/type iron, helping hand, solder or anything you can think of should I consider buying? Utlimatley I would like to replace some of the caps in my preamp. Also never did this before and I am concerned about needing to drain them before working on them? If this is a wise move, how is it done or can I feel safe if they are laying dormant for an extended period of time?

Yep, my name really is Bob.

Parasound HCA1500A(indoor sound) and HCA1000(outdoor sound), Dynaco PAS4, Denon DP1200 w/Shure V15 Type V and Jico SAS stylus, Marantz UD7007, Polk L600, Rythmik L12 sub.

Parasound HCA1500A(indoor sound) and HCA1000(outdoor sound), Dynaco PAS4, Denon DP1200 w/Shure V15 Type V and Jico SAS stylus, Marantz UD7007, Polk L600, Rythmik L12 sub.

Comments

-

Much depends on your budget. The better stuff you buy, the easier it is to do the job quickly without damage to the board. Especially when replacing components. Boards are not indestructible. You can pull traces off boards or pull out the tiny through connectors (like a hollow rivet) that can connect top and bottom of board traces.

We will all have our fav brands too.

An adjustable solder station is a big plus. I like my Weller. Easily replaceable tips in various sizes.

For de-soldering, minimum would be a spring loaded solder sucker. A manual bulb type would be great if you had a helper, but the spring loaded are the better ones to have. Heat the joint and press the button to remove the melted solder. I actually ground a slot in the tip of mine so it can rest on top of the iron and form a better seal around joint. You can get replacement tips for solder suckers.

Best would be a heated solder sucker, like the Hakko in pic. Basically a solder iron tip with hole in it, electric motor vacuum pump when you press the button. Use in circular motion and it removes and can release legs of component from through connectors in boards where they drop out of their own weight.

Some flux would help, nothing with acid! Extra solder. RoHS boards (lead free) are the worst to desolder. Sometimes you have to add flux/extra leaded solder to dilute it some. I love leaded solder versus the unleaded. Much easier to remove it. My fav solder, Cardas Quad Eutectic. While expensive on a big roll, you can buy small amounts (24") from Sonic Craft (home of Sonic Caps).

http://www.soniccraft.com/product_info.php/cardas-solder-qe-24ft-p-521

Some pointy picks, small needle nose help. While a sucker removes most of the solder, you will have some residual on legs of components that cause it to stick to board or board through connector. Heat and press lead away from board/through connector to release it. Using excess force with something that is still partially soldered can rip traces and through connectors out of boards.

In extreme cases, I have used letter drills in finger drill to remove stuck solder in holes.

I like to clean up the solder flux after soldering. Some folks believe leaving flux behind can allow for dust to collect and for bleeder traces. I use 99% isopropyl alcohol. Less water in the higher percent iso.

I also leave some space between components and board.

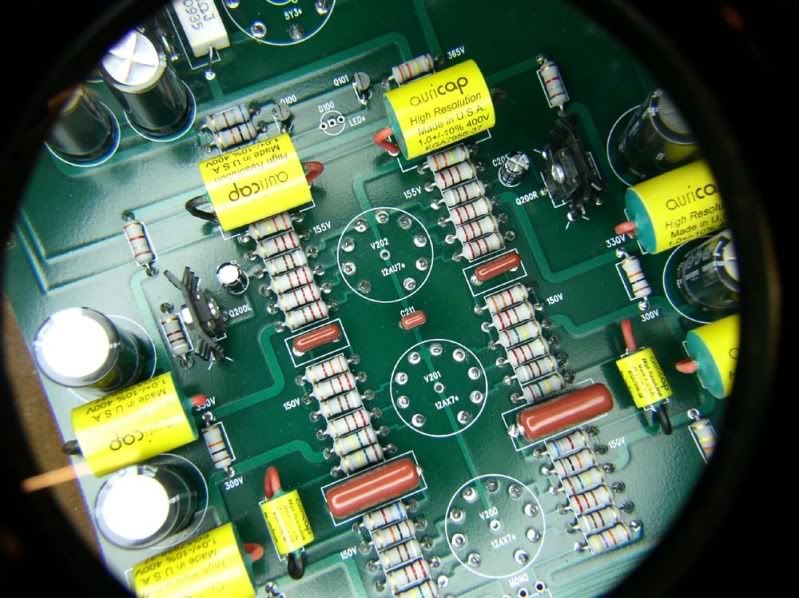

Some of my projects. New construction with Cardas solder.

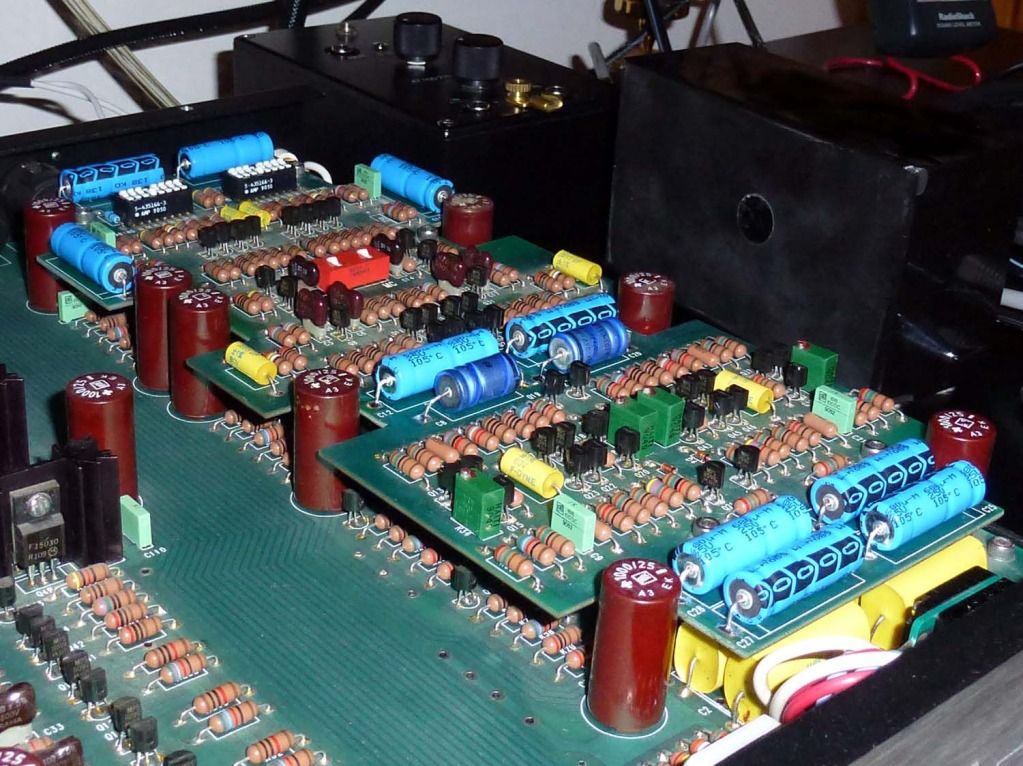

A total recap on a Krell KSL pre.....

....with phono board. Post edited by SCompRacer onSalk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *

Post edited by SCompRacer onSalk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

I have used a Hakko FX-888D for years and a Hakko 936 before that. You can pick one up for just under $100 new. You will need a good solder too. I have used Kester 44 for 30 years and it has never let me down.

-

Some good info, thanx! Nice job on that Krell, heck maybe I should just send you my board and caps!Yep, my name really is Bob.

Parasound HCA1500A(indoor sound) and HCA1000(outdoor sound), Dynaco PAS4, Denon DP1200 w/Shure V15 Type V and Jico SAS stylus, Marantz UD7007, Polk L600, Rythmik L12 sub. -

Are you looking to do through-hole soldering or surface mount? The irons above are good for through-hole soldering. However, recently I tried my hand at surface mount (SMT) desoldering / soldering and found that hot air is the way to go. I picked up a YIHUA 862D+ Soldering Rework Station and had fun repairing my son's hard drive controller board (after practicing on an old junk board).

Stan

Main 2ch:

Polk LSi15 (DB840 upgrade), Parasound: P/LD-1100, HCA-1000A; Denon: DVD-2910, DRM-800A; Benchmark DAC1, Monster HTS3600-MKII, Grado SR-225i; Technics SL-J2, Parasound PPH-100.

HT:

Marantz SR7010, Polk: RTA11TL (RDO198-1, XO and Damping Upgrades), S4, CS250, PSW110 , Marantz UD5005, Pioneer PL-530, Panasonic TC-P42S60

Other stuff:

Denon: DRA-835R, AVR-888, DCD-660, DRM-700A, DRR-780; Polk: S8, Monitor 5A, 5B, TSi100, RM7, PSW10 (DXi104 upgrade); Pioneer: CT-6R; Onkyo CP-1046F; Ortofon OM5E, Marantz: PM5004, CD5004, CDR-615; Parasound C/PT-600, HCA-800ii, Sony CDP-650ESD, Technics SA 5070, B&W DM601