Any Carpenters in the house?

steveinaz

Posts: 19,545

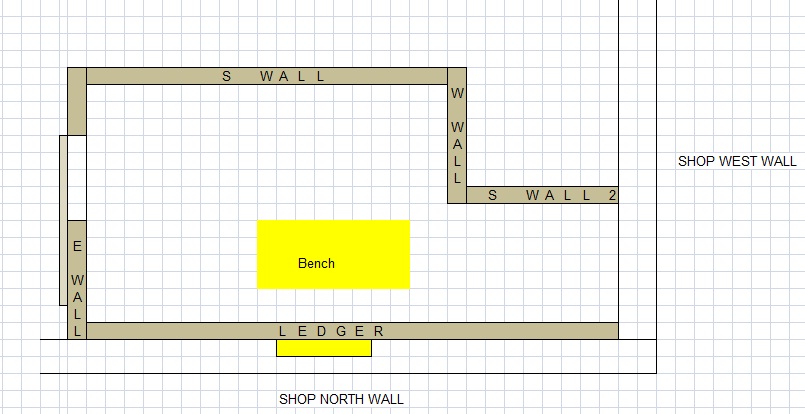

The roof will not be used for storage, and will only need to support my weight for occassional light bulb changes above it. I'm thinking of a rim-joist/framed out setup that will rest on the newly framed wall on one end, then span to a 2x8 ledger aboard attached to the existing structure to either set the joists on edge, or face mount using appropriate joist hangers.

Suggestions, ideas, certainly welcomed. I'm fairly handy and I'm not sweating the framing part at all, but not really sure how to attack the roof part of the project.

In the pic , the span will be from the South wall to the ledger---this is 16ft. The wide outer walls illustrated are the existing RV garage walls (2x6, 19ft high).

Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

Post edited by steveinaz on

Comments

-

I tend to over build everything just to be on the safe side...

I would use 2x10's at a minimum. Possibly double up every other if you notice flex. 16' is a pretty long span and it's going to have to support the roof, and roofing materials tend to be fairly heavy. -

And before I forget.

No matter what we say, always check your local codes.

Don't be afraid to exceed code. They are a bare minimum for safety, no harm in going over bare minimum... -

I would research products similar to these > http://www.bc.com/wood/ewp/simpleFraming/bciJoist.html

It is my understanding that they are much lighter and stronger than conventional framing lumber, also easier to work with.

I wish the joists under my living room had been done this way, it would've saved me a lot of stress and extra work when I finished my basement a few years ago.

As for codes, I don't know what's allowed where you are, Steve.So, are you willing to put forth a little effort or are you happy sitting in your skeptical poo pile?

http://audiomilitia.proboards.com/ -

Hello Steve,

I would use floor joist, up north we call them silent floor joist and they are fairly cheap easy to use, Just call up your local timber supplier till them the span and they will can till you what size joist you need.

Cheers

Roger -

Thanks guys, I definitely want to build it solid, as it's my first project of this magnatude. I was looking at I-Joists as an alternative, albeit an expensive one. The roofing material will be 1/2" (minimum) OSB sheets. It doesn't have to look pretty, as I won't be drywalling the interior, but I do want to do it right.

Should I basically just build a rim-joist type "frame" to cover the first 16' x 20' area, then add joists 16" OC using hangers? I assume I would then secure the roof framing with hurricane ties to the top plate/caps of the framed walls? Is my thinking correct?

I'm absolutely open to alternative methods.....Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2 -

IF there is going to be over 7 feet of height above the "floor"/ ceiling (which ther is, as I understand it) then you need to design the Joist as a floor joist, even though you don't intend to use it that way, who knows, and besides, what happens when you move? THe next people will not know is was only designed as a "ceiling" and not a "Floor"

The IRC has a couple of table that will be helpful for determining the joist and also the ledger and ledger bolts.

TABLE R502.3.1(2) FLOOR JOIST SPANS FOR COMMON LUMBER SPECIES (40# live & 10# dead)

or you could Identify it as a Limited storage attic/ sleeping room (what the code calls it, but there are other things required if it is 'called' a sleeping room) and go with this table

R502.3.1 Sleeping areas and attic joists (30# live/ 10# dead)

Either way it looks like your design is calling for 2X10 DF2 @ 16" OC (depending on what species is available in your area)

Douglas Fir is stronger by Hem Fir, and #1 is stronger than #3 (which is the typical framing material) All framing materials must have a Grading stamp on them.

Also see the details for connecting the joist to the ledger with hangers.

FYI: When you use a hanger, the span length is from the hanger dimension, so it gives you a couple more inches.

http://publicecodes.cyberregs.com/icod/irc/2009/icod_irc_2009_5_sec002.htm

Not sure where you are wanting to use the Hurricane ties. The Ledger bolts to the studs. The hangers are nailed to the ledger with Teco nails. IF you wanted to add additional lateral bracing, you could block at the top of the Ledger and add a LP or A35 clip, but other than that I don't see a need for any hurricane strap, since as I understand it, the top plate would be over 10 feet higher. (19'-8' ceiling - 10" floor joist and OSB = 10.17')

Since you do have the head room, I would Definitively go to 9 feet high plate height or even 10 feet (would still leave 8 feet above it)

Having the extra headroom for swinging boards around, moving things around, or overhead storage ect, would be useful in my book. -

^^Thank you very much, very good informatiom for sure. How do you feel about 2.5" x 9.5" x 16' I-Joists (16"OC) inlieu of 2x10?Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

-

Steve you are looking at a pretty decent span. For 16 feet ceiling joists plan on using 2x10. You can go with 24 inch centers if you'd care to. The upside is that you can gain a lot of storage area, too. I would go heavier with decking if I did that, Like 5/8 ply or 3/4 OSB.

Another option is TJI Joists. They are engineered and truer than dimensional.

And remember to crossbrace midspan.

I would give you some links, but I don't feel like figuring out how. Google the American Wood Council for the span calculator and Weyerhauser makes TJI joists. -

Comparing the "I-joist brand at a local online Lumber yard, the I-joist 210x9.5" are costing $2.37/lf (retail). The SPF #2 better are at $1.62/lf ($26.05 each for a 16footer)

The biggest benefit about any I-Joist is that they are completely true and straight. With Dim lumber, you need to pick the good one out. IF you were a big construction company, that did not have the time to select each one, then the I-joist make a difference. You have the luxery in getting all straight and no knots ect. They cannot afford the time. At least my experience is that 16 foot members are already pretty decent shape, as it takes a good log to even be able to get a full 16 footer out of them. When ordering materials for plates (want straight) I always order at least 16 footers.

IMHO, I-Joist also are a pain when it comes to blocking ect. Yes you can order precut ones, but you still have to deal with the ends ect. With Dim lumber, you can just buy some utility grade 2x10's for that, also saving you money.

First thing is cost (and availability). Just a 'ball park' estimate, you will need

2X10: (14 @ 15') joist for the main area, (3 @ 16') for the small area, (17)* $26.05 (16ft's) = $442

TJI's 210X9.5's will be (14@15') + (6@8') = 258lf @ $2.37/lf = $612 [plus TJI blocking $35 ]

Ledgers are the same (5@16') (85lf/ 16)... (plus $20 for some 2X10X8' studs for the blocking and the small ledgers)

The 2X10's are actually 'stiffer' (total deflection under load at 0.33" vs the TJI-210's at 0.45"

SO I would go with the 2X10 DF2's x 16' with 3/4" Floor sheeting.

STEVES FLOOR.pdf

checked and 2X10 @ 24" oc fail in bending. -

Steve, feel free to PM me if you have any questions.

That way I will get a email on my phone. -

Good info there. I would like to point out that he is framing for a ceiling, not a floor. That's why I say 24" centers.

And he is still going to need cross bracing regardless. -

16" centers regardless of what he is framing. i build interior partitions in sheds all the time, and I haven't met a ceiling yet that didn't become a deck. Build it once, build it right. and the future is taken care of.Polk Lsi9

N.E.W. A-20 class A 20W

NAD 1020 completely refurbished

Keces DA-131 mk.II

Analysis Plus Copper Oval, Douglass, Morrow SUB3, Huffman Digital

Paradigm DSP-3100 v.2 -

I can dig that, but we are talking over a workshop in a RV garage. No way in hell it's going to become a bedroom or living space. At most it will be a place to store Christmas decorations or extra coolers to throw in the RV. There is no good reason to spend the money to frame for a 40-50 psf load when at the most its going to see 20. What's next, 3/4" T&G subfloor for the deck? Glued and nailed? C'mon people...

I would frame it 24" OC. Ledger on the existing wall with joist hangars, and platform on top of your new walls. You will need to box the ends on the new walls with 2x10's. No need to hurricane strap the joists, unless you want to, because the whole thing is inside.

5/8" for the deck if your going to walk on it. 1/2" would hold you, but what the hell. I would "H" clip your plywood though, Steve, because of the span. -

Thank you fellas, I definitely appreciate the insight and assistance. KCOC321, what do I owe you for the blueprint? That's awesome man, appreciate it. So go 2x10, block at center span in the large section, and move up to 5/8" or 3/4" decking. 10-4. I may as well benefit from being able to use the roof as another storage spot.

Tony what do you mean by "You will need to box the ends on the new walls with 2x10's?"

THANKS A MILLION FELLAS!!!Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2 -

When you frame the roof you will put in a ledger on the existing wall at the same elevation (above the new walls) as the ceiling. You will be hanging one end of the joists on the ledger in joist hangars. Then the other ends will be sitting perpendicular to and on top of the new walls. That is called platform framing. (This will give you the full 8' of height in the shop.) In order to do this you will need to make the 16' dimension to the outside of your new wall. You will have to cut all of your joists so the end 1 1/2" inside the outside edge of the wall's top plate, but you might want to any way to make sure all of the ends are square.

The ends of the joists will need to be capped in, so you take another 2x10 and nail it to the ends of the joists with at least 3 nails(I would put 4). This will stiffen that end up so the joists won't roll over on you. It also give you good nailing for the deck on the perimeter. That is called a ribbon box.

KCOC321's blueprint shows a ledger around the room and you hang the joists in hangars. That is called balloon framing. If you do it that way you lose the 9 1/2" of head room from the 8' wall height. You also spend more in hardware.

As far as bracing, you can go solid blocking if you want to. I would just use strap bracing. You put in the top before you put the decking down and nail the bottom from underneath. -

Just carpenter ants

-

Tony, thanks---I got it. My plan was to use joist hangers on the ledger against the existing structure, and then to "platform" the other end on the new walls top plate, with a rim joist face (don't know if I'm saying that right).Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

-

Cool. That's the ticket.

I know you say you aren't going to put up a ceiling, but if it were me I would buy a few extra studs and put in some sheetrock nailers for the future, just in case. Its a lot easier to do now and it might cost you an extra $20. When your anal **** goes to put up the ceiling you'll love me for doing it now... -

Tony, really appreciate your time and effort, thanks man. It'll be a few months before I start, but I'll definitely take pics along the way and share with you guys.

My main goal was to enclose this area so I can heat it. The RV main garage has 19ft ceilings, open rafters, and roof venting that just exhausts any heat right out of the roof. The RV garage itself is 68ft x 38ft, so warming the entire structure is a no-go, LOL.Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2 -

Darn it, I guess I'll be forced to buy a pnuematic frame nailer and a bunch of other tools.Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

-

No problem, my brutha...

Yep, your gonna need a nail gun, a nice new 6 foot level, framing square, worm drive circular saw, reciprocating saw.... Hehehe, Bev is gonna luv you.... -

Framing nailer incoming (Porter Cable pnuematic) should be in my paws Tuesday....hehe.Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

-

...cheapest way is to use a double 2x6 onto short expand and use metal studs and track (3.5") 16" on center .....tied together. very simple. Get fire retardant 2x6's. fire retardant drywall

...can't support weight above except insulation. -

Paslode framing nailers are freaking awesome.

The only thing to keep in mind with the Porter Cable is make sure you have a compressor to run it properly. -

Sent you a PM Steve.. More than I wanted to put in here and clog up the thread.

And you don't owe me anything for the 'sketch', just payin it forwards..hehe -

I've got a NIB framing nailer I'd loan you for cost of shipping if you can cancel your order.

-

Appreciate that Ken, but I've been looking for an excuse to buy one, LOL. It was only $179 at Amazon, model FR350B. I've got a compatible makita air compressor (4.5 cfm @90psi) so I should be good to. Thanks again though, appreciate the offer.Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

-

Here's a general framing question; is there a particular way to determine how to "split-up" a long run of wall? For instance, I have 1 wall that will span 19ft; should I do a 16ft run then 3ft run, or do a 10ft and 9ft run? Assuming of course theres no window or door openings....do carpenters have a rule-of-thumb on something like this?Source: Bluesound Node 2i - Preamp/DAC: Benchmark DAC2 DX - Amp: Parasound Halo A21 - Speakers: MartinLogan Motion 60XTi - Shop Rig: Yamaha A-S501 Integrated - Source: Rotel CD14MkII CD Player - Speakers: Elac Debut 2.0 B5.2

-

Nah. What I do is stagger the split on the plates, making sure to land the breaks on a stud. The top seam gets stiffen by the double top plate.