VTI BL Series Rack Deadening

SCompRacer

Posts: 9,090

VTI BL series racks are popular for the price, but the hollow posts could use some deadening. I've used lead shot and while it works great to deaden and add mass, you have to be careful lifting the sections. Over time, weight and vibes can loosen the lower threaded spike caps. You lift a section, a cap falls off and you have a real project recovering the spilled shot. That happened to me once. One could try a bead of super glue around the lower caps, but it is a metal cap and a painted tube.

Due to a system change, I sold my old double wide BL 503 bought a BL 404. I came up with this method to deaden the tubes. You have to carefully remove the top caps. VTI suggests inserting a long punch through the spike hole and tapping the top cap off. What you use as a long punch is important as a sharp object can dent the thin top caps. Stay at the outer edge of cap, not the center and slowly work your way around.

Get yourself some 1/2" copper pipe insulation. This material was 1 and 3/8" in diameter, perfect to fit snugly inside the tube. Cut to length and insert the insulation in the tube and re-install the top caps. If you want to add mass, get some plastic pipe and plastic caps. Cut pipe to length, glue a cap on, fill with lead shot and maybe some oil and glue the second cap on. Insert in the center of insulation. I used a chunk of 1/2" copper pipe to illustrate. It would be easier to use plastic versus soldering copper pipe.

I used spray insulation once through the spike hole in bottom of tube without removing the top caps, but you have to be careful of excess application. It will continue to foam out the hole and the sticky residue was difficult to remove from the metal cap. That could stain the metal painted surface if it were to get on it, so be careful if you use the spray insulation method.

Due to a system change, I sold my old double wide BL 503 bought a BL 404. I came up with this method to deaden the tubes. You have to carefully remove the top caps. VTI suggests inserting a long punch through the spike hole and tapping the top cap off. What you use as a long punch is important as a sharp object can dent the thin top caps. Stay at the outer edge of cap, not the center and slowly work your way around.

Get yourself some 1/2" copper pipe insulation. This material was 1 and 3/8" in diameter, perfect to fit snugly inside the tube. Cut to length and insert the insulation in the tube and re-install the top caps. If you want to add mass, get some plastic pipe and plastic caps. Cut pipe to length, glue a cap on, fill with lead shot and maybe some oil and glue the second cap on. Insert in the center of insulation. I used a chunk of 1/2" copper pipe to illustrate. It would be easier to use plastic versus soldering copper pipe.

I used spray insulation once through the spike hole in bottom of tube without removing the top caps, but you have to be careful of excess application. It will continue to foam out the hole and the sticky residue was difficult to remove from the metal cap. That could stain the metal painted surface if it were to get on it, so be careful if you use the spray insulation method.

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *

Post edited by SCompRacer on

Comments

-

The Dude is a craftsman! Very nice, Rich. Is sand a possible viable option with this rack?

Just in awe of your DAC each time I see it. -

Rich,, thanks for posting that. What a creative fellow you are!JC approves....he told me so. (F-1 nut)

-

Thanks Mike and George! Just trying to make the stuff I can afford a little better.

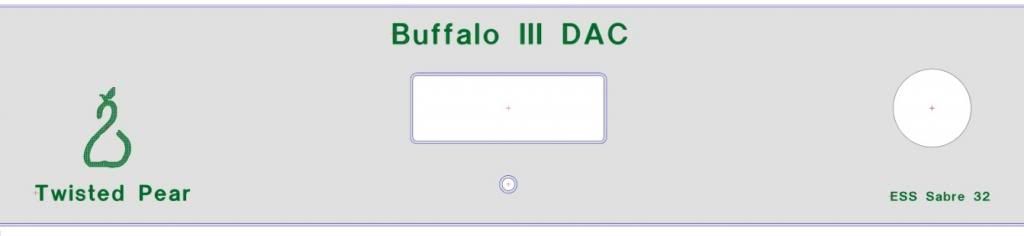

Mike, I have an enclosure in progress for the single BIII DAC I have built. Once again I turned to modushop in Italy for a Pesante 2U (88mm x 435mm, 300mm deep) as they machine both sides, anodize after machining and offer a fully vented top cover. Here is a partial narrow screen print of the .svg file. Silver 10mm front panel machined both sides (get that LCD closer to front), chamfered edges on openings, recessed manual control knob, white on blue LCD, remote control, shunting power supplies, discrete balanced out, RCA out, headphone out. Inputs, maybe USB to I2S and SPDIF coax. I have two guys that want to demo it...if it gets past them I'll send it to you for a trial. Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

Hey Rich, I just wish I had a VTI rack that I could tweek a little! Nice touch!

-

Great idea. I have a lamp that used to drive me nuts when the ball on the end of the pull chain would bang against the hollow metal post. Frost King (rubber) also makes a pipe insulation made with Armacell which is nice and dense and great for deadening. It may even work better than the Frost King foam.Stan

Main 2ch:

Polk LSi15 (DB840 upgrade), Parasound: P/LD-1100, HCA-1000A; Denon: DVD-2910, DRM-800A; Benchmark DAC1, Monster HTS3600-MKII, Grado SR-225i; Technics SL-J2, Parasound PPH-100.

HT:

Marantz SR7010, Polk: RTA11TL (RDO198-1, XO and Damping Upgrades), S4, CS250, PSW110 , Marantz UD5005, Pioneer PL-530, Panasonic TC-P42S60

Other stuff:

Denon: DRA-835R, AVR-888, DCD-660, DRM-700A, DRR-780; Polk: S8, Monitor 5A, 5B, TSi100, RM7, PSW10 (DXi104 upgrade); Pioneer: CT-6R; Onkyo CP-1046F; Ortofon OM5E, Marantz: PM5004, CD5004, CDR-615; Parasound C/PT-600, HCA-800ii, Sony CDP-650ESD, Technics SA 5070, B&W DM601