Weller 100/140 Watt Iron Too Much?

smglbrth

Posts: 1,496

Hey all, with all the talk about changing caps on crossovers and such I'm thinking of tinkering with it. However, seems that most persons use lower wattage irons than the one listed above. When I was younger I used one that looked just like this Weller but it was with things other than crossovers. Is this too much of an iron to use on more delicate work? The two reasons I ask is because I have a Lowe's gift card to blow and I might use it for other, bigger projects down the road. Should I be afraid of "melting" something with this one? Lowe's does have lower wattage models I could get, just trying to get an opinion from those of you who do your own mods.

Also, do you get a certain type/brand of solder when modding?

Thanks!

Also, do you get a certain type/brand of solder when modding?

Thanks!

Remember, when you're running from something, you're running to something...-me

Post edited by smglbrth on

Comments

-

a high power soldering gun (or iron) like that isn't for PCB work, or solid state components in general (i.e., ICs, transistors), but it's good for heavier jobs - soldering to grounding tabs on chassis, de-soldering for restoration, point to point work, cables, stuff like that. It would be fine for point to point crossovers; try not to over heat capacitors. One can always use a heat sink (a pair of hemostats clipped between the soldering point and the component is way better than nothing - heat-sink-wise).

For solid state stuff, 30 watts or so is good; variable power (and thus temperature) is even better.

It pays to buy good soldering equipment! -

Thanks, I like the idea of a variable temp model so guess I'll have to go somewere else besides Lowe's. I know parts express has some decent models so I'll check there as I've seen a couple recommendations for different irons from there, here.Remember, when you're running from something, you're running to something...-me

-

You'll love dial a temp! I have a Weller WES51.

For solder, I really like the Cardas Quadeutectic (leaded). The flux residue cleans up easily too. Always wash the flux residue off with the highest concentration of Isopropyl alcohol (90% IIRC) you can get your hands on.Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

FWIW: I like the Weller soldering stations, and I like lead based solder :-) ahh, the smell of rosin and lead in the morning...

-

Yeah can't go wrong with a Weller station.

-

I am hakko man myself.

in the end its all just heat. generally speaking.:loneranger::loneranger:

I support the FX-888.

it has everything you need and more.

adjustable heat.

Sponge for flicking, i personally never touch my tip to a wet sponge, heat shock wears tips out, i just flick the excess solder onto it.

Wiremesh cleaner, the best thing ever IMHOP, no thermal shock and it scrapes away old crusty flux.

ceramic holder for your solder pen.

the pen is comfy.

the whole station is small and saves space.

ill walk ya thru my setup. do you need all this? No. but I do soldering as a hobby, I am always making those velleman kits and other fun electronics and cables ect. Plus if you put more effort into your skills and gear your joints will be better too, skills first though.

If you want to PCB solder heat control is nice, it is not necessary but its a great luxury to have. And if your unsure of your skills it can save your pads and traces. If you touch a 800f iron on a pad and keep it to long you'll burn the board and lift the pad and trace. The pros crank their irons but they can make something like 50 joints a minute. they just pop pop pop. With keeping your iron close to the melting point of your solder it allows you a nice buffer and a safety zone for your board.

for playing with solder i suggest get your self two of those helping hands things. take one apart and put the claws onto the other. this way you can have 2 hands hold the board and 1 or 2 hands hold the leads or other things. Its just helpful, check your local electronic store before radio shack, i got those from my local electronic store for 8.99 each, the shack gets 16~20, i have seen them go for. again, not needed but will make your life so much easier.

If your going to hunch over your work or plan on getting into soldering as fun, i suggest to get fume extraction. especially if your going to get right up to your work. you dont have to, but hey, if you want asthma go for it.

That little hakko thing is nice, or you can get inventive and get a carbon filter from your local fish supply store and then put that on a hepa filter, then on a fan as a diy type deal. Honestly, by the time you make all the mounts, spend the money for parts you will most likely have spent the money you would need to get one that is designed for that specific purpose.

If your only modding once, you dont need it at all. just get a fan, blow towards you and open the doors.

get the smallest diameter rosin core solder you can, .022 or .015, this will decrease the contact time you need to melt the solder to the board and lead. Less time = less heat. less heat= less damage, to board, pads and traces and components.

Maybe you know this already but rosin core not acid core. Lowes has both, and like i said maybe you know this but its good to cover all basis.

flux is your friend! your best friend in fact, yes the core of your solder is rosin flux but a dab extra will work wonders. flux will clean the pad and hold the heat for the solder to really wet. i am not sure of the difference between brand fluxes, i like the rat shack because its a past and i can put on a tiny tiny bit. Flux your joints when you desolder too. Flux is just the magic juice that makes everything go.

This is another point of heat control. If you had your 100-140 watt iron your flux would more than likely burn off very quickly. with temp control you can hang out very close to your solders melting temp and then the flux will only bubble a little and stay in liquid form letting the solder take a great joint. Just a fyi.

I have heard before you should get a little solder pen and a gun for the larger work like grounding tabs and ect.

I take the other end of the stick, if you get a station or a pen with enough heat just get more tips. for each function, tips are only 5~8bucks each, a gun costs much more.

from left to right, i have the chisel tips in smaller ish to medium size for solder cup and terminal joints where a conical tip wont do or a hoof tip wont fit. conical tips, well i haven't found too much use for these but most iron come with a conical tip, My favorite and most useful, in my experience, are the hoof tips. These have a 45degree face, there are 60d but meh its up to you. these tips rock, turn it on its side and you kade great contact with the pad and the flat face contacts the joint. awesome! the larger face ones i use for wire, solder cups and the tabs that were mentioned. very friendly and work well.

all in all, get tips before a gun and save some dough.

get your self some hobby brushes. the metal ones are the acid brushes, from any solder supply store, hobby lobby meh they are all over. You have to trim them otherwise they are not stiff enough to scrub away the flux.

i recommend the masters touch scrub brushes from hobby lobby, or a store like that, they are filbert style and they are nice and stiff, perfect. and all you need is one set, the tiny one for flux and the middle and big ones for cleaning.

IPA, or isopropyl alcohol, will clean rosin flux. get 90+ percent. Usually you can find 91 at walgreens ect. Ask, some pharmacies have 99%. the more pure the less water and junk in the alcohol.

Well, in that book i hope you found something useful.

Get your self a solder station, solder, flux and a way to clean it and your good to go!:loneranger:

enjoy modding, its fun and the rewards are worth it.

esr:loneranger::loneranger::loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

forgot to say,

if you have time, watch this place, they run sales from time to time, the fx888 was onsale for 69.99 but its back to its regular price.

they also have many other solder stations and pens. its your play ground.

www.tequipment.net

esr:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

^^^^Man, you went all out with that review Esreuter.

That was a good read!Testing

Testing

Testing -

Why thanks pepster.

I like to solder, its lots of fun.

I snapped another photo of some of my other goodies but i didnt post it because i figured my nerd meter went to 11 already.

but hey why not take it to 12 eh?

this is just stuff that i felt was overkilling the over kill.

other things i use to finish or desolder ect.

i got the pump bottles not for the ESD but, i dont like to use dishes for IPA and flux, then eat off them. I likes to keep my chemicals separate. And they are really nice because it keeps your alcohol from evaporating on you.

Solder sucker, i like that over wick, but can use wick in tight spots.

safety glasses.

two other bottles are for if i run into no clean or water soluble flux. I put in 2 drops of Palmolive dish soap and it really cuts the flux and its activator salts well, no dye and no scent is the best.

Then distilled water, for rinsing and mixing the soap, dont need any mineral build up on your joints.

brush sets for each and meh. All for fun.

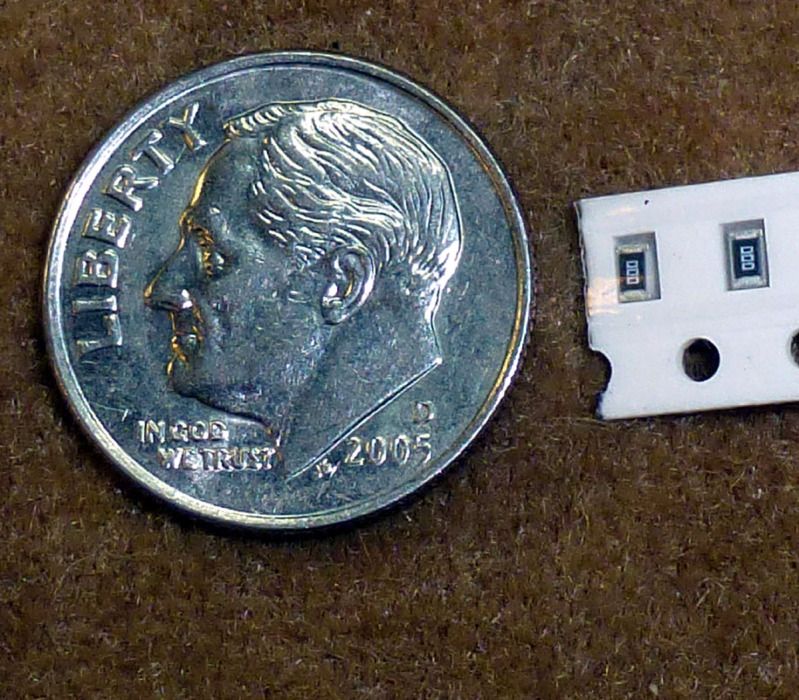

my latest conquest is surface mount devices. Tiny, delicate, heat sensitive, this will really hone your skills.

only problem i have, i can only attach SMD, i dont have the tips or hot air guns to free SMD chips and pins. Properly, i could always heat and yank. yikes.

smglbrth, dont mind this post, it was just to spike the nerd meter to a new high.

again, all you need is: station, flux, solder and a way to clean it.

ESR:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

mhardy6647 wrote: »and I like lead based solder :-) ahh, the smell of rosin and lead in the morning...

I love the smell too! I don't care for the RoHS solder. One of my recent mod projects was an RoHS compliant board. That stuff was very hard to remove with solder sucker and wick.

Esreuter, my latest project involved installing 12 SMD jumpers. I also repaired a computer mother board long ago when I broke a SMD resistor off installing a CPU water block. I am into a 9" lighted ring magnifier for the small work. Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

oohh thats cool.

I love watching the videos when the people do the drag solder.

just put down a stick of solder, flux and then drag.

Yeah ill have to invest in a mag glass for the smd, they get pretttttyyy small.

and some tweezers. I thought i saw a heated tweezers for the hakko, but it may have been a model up from mine.

well, as i think of it, what is the name of the special solder additive that expands the plastic or liquid state of solder for up to 10+ seconds.

that is a cheater way to remove some smd chips.

ill have to look it up.

every had any chance to mod the xbox controllers and fix the mother boards?

ESR:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

My early days had me helping my father doing plumbing. Heat draws solder. I did copper water, drain and even some lead drum trap work in old buildings. Now there is a lost art. Just enough temp to soften the lead, an asbestos glove for wiping the joint. Too much heat and blop, it hits the floor. Too little, a poor leaking joint. My uncle was a TV repair guy, back when transistors were taking over tubes.

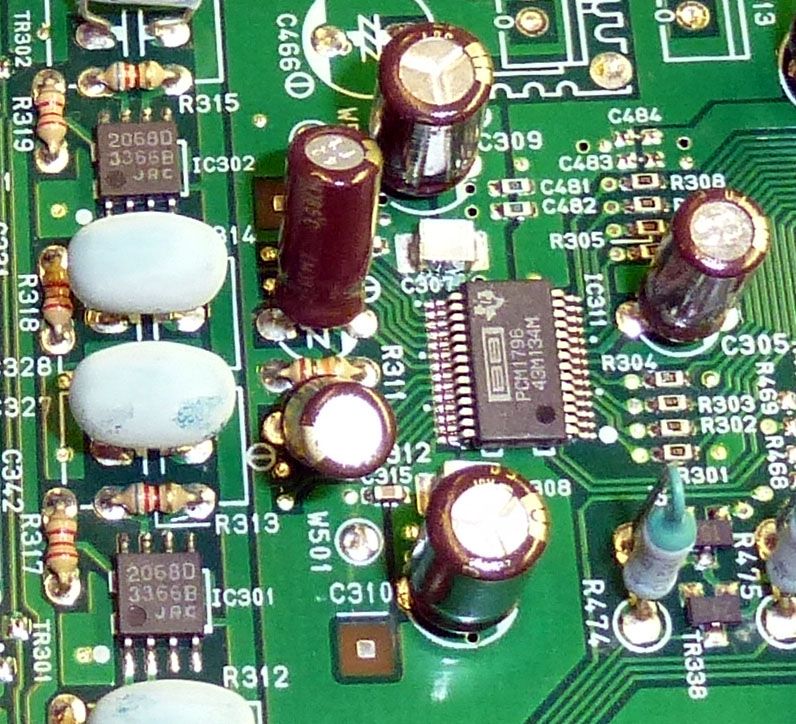

I do have a nice pair of fine tip tweezers that came with a protective tip. Very helpful for removing SMD's from the packaging and placing/holding. I do confess to some Playstation modding ~ 15 years or more ago. My eyes were much younger then. My next challenge will be soldering tiny wires to the audio board of a Denon DVD player by a Burr Brown PCM1796 to extract PCM (CD) and DSD (SACD) data for my external DAC. Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 *

Salk SoundScape 8's * Audio Research Reference 3 * Bottlehead Eros Phono * Park's Audio Budgie SUT * Krell KSA-250 * Harmonic Technology Pro 9+ * Signature Series Sonore Music Server w/Deux PS * Roon * Gustard R26 DAC / Singxer SU-6 DDC * Heavy Plinth Lenco L75 Idler Drive * AA MG-1 Linear Air Bearing Arm * AT33PTG/II & Denon 103R * Richard Gray 600S * NHT B-12d subs * GIK Acoustic Treatments * Sennheiser HD650 * -

ooo. a real hacker.

non of that code stuff. getting inside and rewiring the brain of the machine. or piping the info before it gets manipulated.

i like it.

ESR:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

Quick question,

You guys ever use Wonder solder?

Your thoughts?Testing

Testing

Testing -

Esreuter - That was great read and very insightful. Nerdy?, heck no I thought it was pretty cool! I have some strong points as well which don't apply here and Nerdy isn't the right word for any of it!

Thanks for the info and pics!Remember, when you're running from something, you're running to something...-me -

no problem.

glad to help out the community.

esr:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

You have also picked a great way to kick the ball off into soldering.

of course the best way i think are the velleman or little electronic kits like them for ~20 bucks, not much to worry about ruining there.

this way, your speakers are at risk, but you know how many guys are here who can fix your XO if you break it?

lots! i am sure for a fee but you have a decent safety net.

plus, from my monitor II PCBs and the other PCBS i have seen in photos they are all single sided. You have much less to worry about in terms of heat, time and PCB expansion.

Dual sided boards you have to watch out, in the thru hole they have a copper tube, i forget its exact name, i think its just a eyelet. When you touch a hot iron to PCB of course it expands, and too hot on a dual sided PCB will pop the eyelet out, pads and stuff might survive but you have this little copper tube just rattling away.

your going to have fun and lots of enjoyment when the mod is finished, then the 200 hours break in, it just gets sweeter as the ball rolls. My monitors are kickin something new every time i watch a movie now. I notice a new tone, or some clarity on voices or crashes and it sets me back in my chair like whoa nice, still giving out surprises.

on a side note what speakers are you modding?

ESR:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

I actually use three separate adjustable Weller soldering stations. Each one has a different size/style tip so I don't have to swap them around.

I learned to solder when I was a kid building Heathkit Ham Radio gear. Today I use mine primarily for rebuilding circuit boards for solid state pinball machines. How's that for "nerdy"?

lol

Check this out. My company is moving to Chicago and they had some equipment they weren't taking. They held an auction for employees last weekend and only six showed-up for it. I picked this awesome electrical workbench up for a song ($10.50)! I had been wanting one of these for a long time.

It's a Made In USA heavy-duty professional-grade "Flexible Montisa" workbench with 12 protected outlets, ball-bearing drawers, and a 36" x 72" workspace in almost new condition. :biggrin:

-

I'm considering doing my 8t's and new acquired 7C's. They both sound great now but I realize it's not going to last forever. I made the mistake of already telling my wife that if I actually get this done I could have these speakers for the rest of my life (as in not only rebuilding the crossovers but also making sure the cabinets are still sealed and replacing the foam tape on all the drivers when done, binding posts, etc...). You know, I just don't see modern speaker building getting better in terms of price/performance. However, since I haven't purchased anything "new" lately, guess I don't know for sure. The only thing that really worries me about the 7C's is the passive going south, one thing at a time!Remember, when you're running from something, you're running to something...-me

-

Now thats epic.

and it was a steal.

even if you dont do electronic tinkering a desk with built in power like that is a gift.

ill give ya 11$ for it.

you make .50!!

all profit.

ESR:loneranger:AVR: Sony 5600ES

Center: CS2II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Front: Monitor 70 II (Clarity Caps PX, Perfect Lay coils, Mundorf resistors)

Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

Rear Surrounds: Monitor 40 II (Clarity Caps PX, Perfect Lay coil, Mundorf resistors)

More to come :biggrin: -

gc - that is simply an awesome bench!

-

Yeah I think I got a good deal. I had been looking for a nice electrical bench like it for some time and even the cheap Harbor Freight and Global West Chinese-made benches with similar features were around $600 new.

These heavy-duty Flexible Montisa made in USA (Michigan) benchs like this one list at close to $2,000 new! Flexible Montisa is widely used by the government, schools, and major American corporations. This thing looks brand-new. Even the drawers are mint.

Here's the website: http://www.flexiblemontisa.com/ -

I would go $12 on it if you will include shipping, thanks. :razz:

That is an awesome workbench!

Congrats man!

What a score!Testing

Testing

Testing